Precast construction using concrete trusses for waste sorting building

In the Bavarian municipality of Eitting, a factory building was realized with a self-supporting roof structure made of 50m-long beams. Laumer Bautechnik manufactured them using precast concrete segments, which were only connected to each other at the construction site in a friction-locked manner.

In particular, precast construction, which is characterized by its cost-effective design, provides a wide range of opportunities for realizing sustainable building structures in the future too thanks to high-quality production alternatives. As an example, Laumer Bautechnik GmbH located in Massing has designed and produced, just recently, a large number of concrete trusses for the construction of roof structures.

Certainly, the roof structure for a large waste sorting building in Eitting near Munich is particularly noteworthy in this regard. The hall building, designed as a classical frame construction using precast concrete elements, is spanned by a self-supporting roof structure with a support span of 50 m. Upon request of the client, the roof structure was to be designed in prestressed concrete beams for reasons of sturdiness and because of the fire protection specifications.

In case of a classical TT beam design for the planned beams with a length of 50 m, a roof pitch of 5 degrees and a ridge height of 3.50 m, the overall weight per beam would have amounted to approx. 80 t. These framework conditions are very difficult for production, storage and transportation of the roof beams. Only a few precast concrete companies are in the position to manufacture prestressed concrete beams in this dimension. Therefore, a new innovative construction concept was pursued and implemented for this building project, so that the manufacturing precast concrete plant was able to realize the roof beams.

Innovative construction type

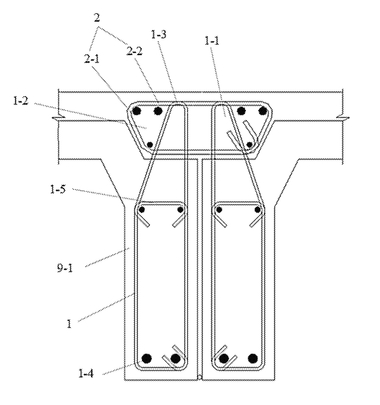

In order to simplify the above-mentioned framework conditions, according to this principle of design, the roof beams were planned as trusses to reduce the weight, the ridge triangle was „cropped“ to lower the component height, and to shorten the component length, the beams were produced as segments in two pieces that were connected to become one part by means of innovative reinforcing steel couplings at the construction site later. At the same time, the protruding reinforcing steel bars on the front side of the top and bottom chords were coupled with each other at the center of the beam. Each beam half was separately pretensioned by means of strands, in order to make use of the favorable effect of pretensioning, in particular, in respect of the stiffness of the beams. External pretensioning was not applied additionally in the joint area of the reinforcing steel couplings.

This concept finally allowed reducing the weight of the beams to 63 t, cutting the transport length of the beam segments into halves at 25 m and diminishing the component height to 2.80 m. For transport alone, this resulted in quite remarkable saving potentials.

Structural concept

For the implementation of these concrete trusses as separated, prestressed beams, a lot of detailed structural verifications had to be provided. Apart from the usual verifications in the limit states of load-bearing capacity and serviceability (SLS) in the stage of construction and in the final state, many individual details had to be solved, such as at the joint, for the connection of the component halves, for attaching the compression and tension struts, regarding the tilt stability in the construction state and the anchoring concept. Special attention was paid, in particular, to the joint area with the enormous compression and tension forces acting in the top and bottom chords, in order to safely transfer the occurring loads in the stage of construction and in the final state. With the aid of the reinforcing steel couplings, it was possible to transfer all forces in the stage of construction immediately after connection of the building components. Additional, defined steel plates were inserted as pressure contact merely in the top chords. For the final state, the area of the top chords was additionally grouted with a high-strength, low-shrinkage concrete compound. As protection against corrosion, the reinforcing steel couplings used in the tension zone were also grouted after the installation of the beams.

A virtually monolithic condition of the beams was consequently achieved after the grouting works. Tilt stabilization in the final state was obtained by means of a roof framework made of steel, classically designed by compression and tension struts as well as diagonal members.

Production

The concept of dividing the building components simplified the construction of formwork in a resource-conserving way, since the molds had to be made only for halved truss lengths and afterwards, they could be used for all beam segments. In combination with the easy-compacting and/or self-compacting concretes, the beam molds could be designed as vertical formwork, since the highly flowable concretes are filling all areas of the mold without the need of additional intensive vibration.

Two different concrete mix designs were used for the production of the beams: A concrete with a higher proportion of superplasticizer (consistency class F6) was used for the confined area of the struts and bottom chords. A „normal“ concrete with lower flow characteristics was used in the upper area of the beams, so as to realize the top chord slope of 5 degrees. The two concrete types were made compatible particularly concerning the similar rate of hardening, to avoid the formation of a horizontal separating joint in the web area of the beams. The concrete strength class of both concretes was C50/60.

Transport and assembly

By dividing the beams, transport was much easier, while reducing the transport costs substantially. The two beam halves were carried to the construction site in one load, on site aligned in suspension on a crane with the aid of an auxiliary construction and then connected on the front side by means of the reinforcing steel couplings in a force-locked manner. Afterwards, the beams were placed on the precast concrete columns with the aid of two truck-mounted cranes. Then the joints of the beams that are non-tilting in the erection state were subsequently grouted with a high-strength, low shrinkage concrete compound so as to be able to transfer all loads in the final state too. In addition, a roof framework was installed for tilt stability.

Saving potentials and more advantages

Substantial saving potentials come along with this method of construction. The slender cross-sections in the strut area reduce the concrete consumption considerably, thus also reducing the weight of the beams accordingly. Moreover, the required amounts of reinforcement diminish. The resource-conserving savings of formwork material is another positive aspect of this construction method. Owing to the reduced beam weight and the halved transport length, it was possible to cut the transport costs for this construction project considerably.

Apart from the aspect of structural stability, aesthetic criteria pay an important role too. The resolved truss area provides the roof structure with a spatial openness and lightness; even a flexible use of the same as an installation level is possible. In addition, the engineering approach of the load-bearing effect of the compression and tension struts is impressively reflected by the structural design of the truss structure. Requirements concerning fire protection are met by reinforced concrete elements anyhow, thus allowing simplified verification.

Conclusion

In particular, when it comes to large spans, truss systems with the positive characteristics as mentioned above can be a reasonable alternative. The concept of dividing the beams and connecting them later on site also allows precast concrete plants with restricted formwork lengths to manufacture wide-span systems cost-effectively. This also leads to new production opportunities for precast concrete plants with limited production and storage lengths. The production range can be expanded considerably in this way.

The entire project report (in German language only, incl. supplementary diagrams, 3D models and author vitas) can be found in Betonbauteile yearbook 2024.

Text: Christoph Schmidhuber