Limitation of crack width in non-metallic reinforced concrete components

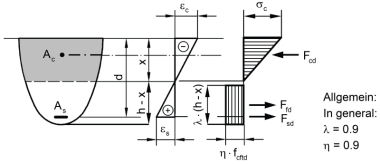

With the introduction of the DAfStb Guideline “Concrete members with non-metallic reinforcement”, the verification of crack width limitation is standardized for the use of non-metallic reinforcement in Germany for the first time. The concept of predicting

the crack width used for designing steel reinforced concrete members is adopted to non-metallic reinforcing bars and grids. A testing and evaluation procedure is recommended for the material-specific determination of the characteristic value of an average bond stress of reinforcement grids. The proposed approach

currently leads to conservatively determined

bond stresses of low value, which require

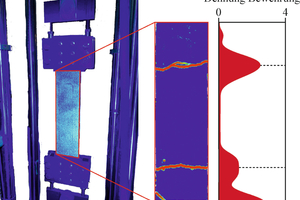

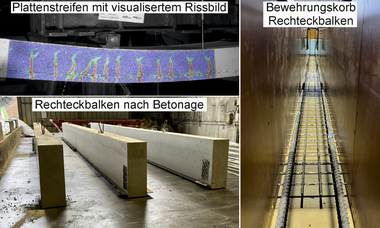

higher reinforcement ratios to limit the crack width. Therefore, explicit test methods to determine the bond stress are necessary in the future. Crack opening tests, in which a single fibre strand is placed centrally in a concrete specimen to conduct

a uniaxial tensile test, are one possible option. The reduction of the concrete cross-section to a minimum providing a predetermined crack initiation allows for a continuous measurement of the crack opening. The crack opening is set in relation to the reinforcement stress to derive a bond stress that allows for an appropriate application of the design concept proposed in the DAfStb Guideline to verify crack width limitation.

It is apparent that the non-metallic reinforcement experiences significantly greater strains in the serviceability limit state than when using reinforcing steel. Recent investigations with a continuous measurement of the reinforcement strain using fibre optic sensors confirm this. The material properties of non-metallic reinforcement therefore inevitably lead to a reconsideration of the crack width limitation when planning

a concrete struture, as the reinforcement ratio determined in the service ability limit state, including deflection

control, are often decisive

for design.