Mineral foam for use as a structural core layer in concrete sandwich panels

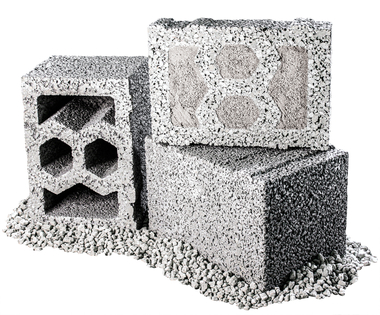

In the construction industry, the use of prefabricated solid structural components is increasing constantly. This is because industrial prefabrication ensures a high quality standard while reducing construction time significantly. More specifically, installing multilayer precast reinforced concrete panels fitted with inside polystyrene insulation has become a widespread approach. This construction method can generally be used to create hybrid components that fulfill both structural and energy efficiency requirements. However, because of the solid bond between the polystyrene insulation elements and the adjoining concrete shells, such components pose a significant challenge in terms of their subsequent recyclability. Separation of the materials is a complex process owing to the different composition of the individual layers, which is why components can be fed back into a closed material cycle only partially and at great expense. As an alternative to petroleum-based insulation materials, mineralized foams can be used, which demonstrate a clearly superior performance.

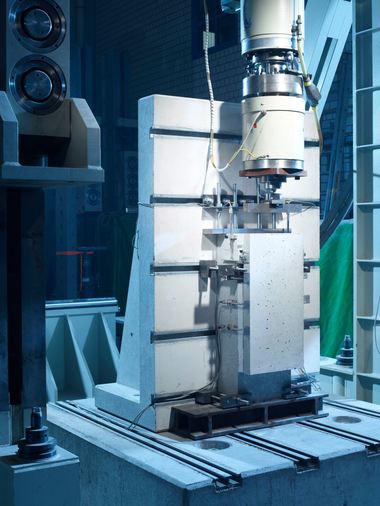

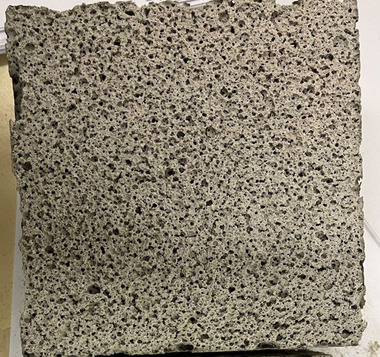

This is the starting point of the “ReCoWall” research project jointly conducted by the Department of Concrete Structures and Structural Design at RPTU and Zuber Beton GmbH. Replacing polystyrene insulation with mineral foam aims to establish a fully reversible composite cross-section in which the core material can have a positive effect on load bearing and deformation behavior in addition to its insulating effect. To investigate this issue, extensive testing needs to be conducted at the material and component levels. Initial tests concentrated on the mechanical properties of the mineral foam. The mix designs reached compressive strengths of up to 3.30 N/mm². The resulting stiffness values of the material also suggest that the core layer contributes to the load-bearing effect, which will be verified in the further course of the project by means of component tests and related numerical simulations.

This project is co-funded by ZIM; of the Federal Ministry for Economic Affairs and Climate Action and AiF Projekt GmbH.