Modular production plant for non-autoclaved aerated concrete

NAAC – lightweight aerated concrete, is a newly developed construction material from Multicon, with identical and/or similar production characteristics as normal aerated concrete (AAC). For its manufacture, however, energy-intensive production steps, such as grinding of sand and hardening under steam pressure are omitted – with the result that the entire system, according to the supplier, can be offered at approx. one-third of the price of conventional AAC plants. Both fly-ash and granulated blast-furnace slag can be used as cement substitute.

In contrast to cut aerated concrete, wall panels of any size can be manufactured with this new construction material, and the space required for production is only 50 % of alternative methods. Existing AAC plants can be combined with this new technology without difficulty. Furthermore, 24-hour operation is not required, and hardening takes place under energy-neutral conditions, with normal pressure and/or self-curing at 60° C.

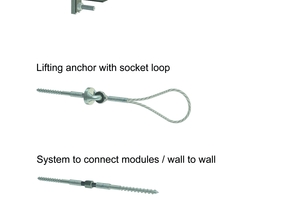

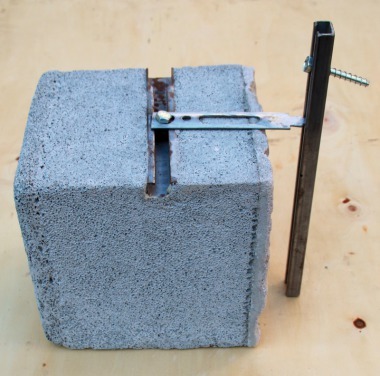

In addition, with NAAC all installation parts can be fixed in the formwork, whereas with cut AAC, according to the supplier, they are subsequently anchored using drilling/gluing technology.

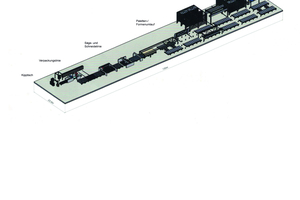

The joint module – which provides predetermined breaking points for wall panels in earthquake-endangered areas – can also be manufactured with low gross density, using this lightweight aerated concrete. These modular production plants contain the following modules:

A fully automatic mixing plant, including a pore-generation station

A curing chamber

Pallet / formwork circulation

A sawing and cutting line

A packaging line

A tilting table for 90° lifting of large wall panels.

A statement from Precontech Managing Director Dieter Rausch summarizes this system: “The ability to manufacture lightweight aerated concrete, without energy-intensive autoclaves – in the form of large walls, panels or blocks – will revolutionize this market. These benefits will result from both cost-efficient manufacture, as well as from installation with fewer joints, which will enable significant economic savings. We, as Precontech, are the sole owner of the industrial property rights for this connection technology.”

Initial negotiations underway

In Saudi Arabia, talks with three major manufacturers have already taken place. They showed great interest in combining their existing production technology in the future with autoclaves with the new plant without autoclaves. This will also enable manufacture of large wall panels.

The same applies for the worldwide largest aerated concrete market, India, where initial talks with aerated concrete manufacturers took place at World of Concrete Mumbai.

In the Philippines, the first plant without autoclaves will be built to manufacture large walls, as well as floor and roof panels, for a large residential construction project on an area of 18 ha.

Serious talks are currently underway with the largest manufacturer of aerated concrete in South Asia, with plants in Singapore, Malaysia, Indonesia and the Philippines.