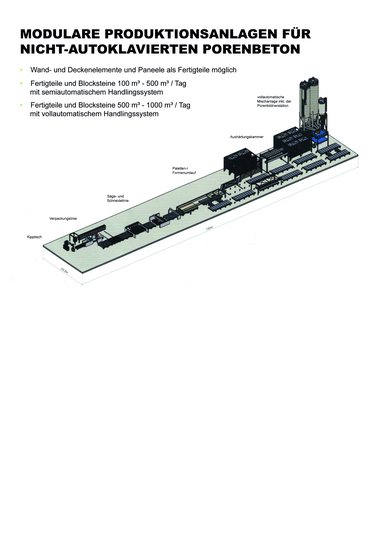

New modular NAAC production system

Megapore offers the plant and equipment needed for the production of non-autoclaved aerated concrete products, ranging from blocks and panels to complete sandwich wall elements (NAAC). The frequency-controlled colloidal mixing technology produces the highly reactive nano-colloidal suspension, on which the Megapore lightweight concrete is based, by means of the for this purpose specially developed frequency-controlled colloidal mixing technology.

No autoclaving necessary

The capital investment in a Megapore production system, according to the manufacturer, is considerably less than that required for the typical production plant for autoclaved aerated concrete. Because the conception of the plant engineering also allows for the installation of smaller as well as mobile plant, cost-efficient operation is possible also in regions where the market cannot absorb very large quantities of lightweight concrete products, or where long transport routes restrict competition. Since the Megapore plant engineering requires no autoclave, 24-hour production is not required; and the footprint is around 50 % less.

An existing Megapore production plant can be easily enlarged to meet growing demand; the Megapore production process, moreover, is also suitable for standard concrete products.

The modular production systems are suitable for the manufacture of precast wall and floor elements as well as panels. The production capacity for precast elements and blocks with a semi-automated handling system ranges from 100 to 00 m³/d and/or with a fully automated handling system 500 to 1,000 m³/d.