ModularesBauen congress 2022: Expanding knowledge and networking

The 2nd ModularesBauen congress was held in Aachen in September 2022. The event was co-hosted by Aachen Building Experts e. V. Its members include various institutes of RWTH Aachen University as well as concrete-processing companies such as Florack, Lucem or Nesseler Group.

Prof. Markus Kuhnhenne, director of the Institute of Steel Construction at RWTH Aachen University, welcomed the approx. 170 congress participants to the Aachen Technology Center (Technologiezentrum Aachen; TZA) on the city’s Europaplatz. Prof. Kuhnhenne reminded the audience of the wide spectrum of modular construction and pointed out that this forward-thinking technology cannot be considered separately for the different construction methods. As a matter of fact, achieving the greatest possible degree of sustainability requires not only comparing all types of construction. Rather, the best of each building design should be applied, striving for hybrid implementation. In order to even begin to cover the wide range of modular construction, the hosts, consisting of Aachen Building Experts e. V. and Technologie Marketing AG (TEMA), had put together a packed program of 28 presentations for the two-day congress.

Wide range of presentations

The following presentations were of particular interest to precast concrete construction:

Andreas Schimmelpfennig, managing director of CREE Deutschland GmbH, gave a lecture on the merits of hybrid timber-concrete construction, which uses in particular composite floor slabs in which thin concrete surfaces are supported by wooden joists. CREE Deutschland GmbH is a subsidiary of Zech Group, which also includes BWE-Bau Fertigteilwerk GmbH based in Lemwerder. CREE and BWE are working closely together on the timber-concrete composite floors.

Dr.-Ing. Sisi Zhang, who is working with the Institute of Concrete Structures at RWTH Aachen University, gave a lecture on the 3D printing of reinforced concrete using the AMoRC method. Concrete printing as such is widely known and used. Dr. Zhang is concerned with introducing steel reinforcement into the printing process, that is, the simultaneous printing of concrete and steel.

Matthias Kalthoff, M. Sc., from RWTH Aachen University presented a new type of floor slab that consists of extruded carbon-reinforced concrete. The floor slab has relatively thin covers on the top and bottom sides, which are connected by arrays of undulating carbon-reinforced concrete strands arranged in a cross pattern. As a result, the fairly thick floor slab has a considerable load-bearing capacity but is nonetheless largely hollow on the inside, which can be used for the installation of building utilities.

On the second and final day, a panel addressed integrative solutions in particular forconstruction and refurbishing work involving existing structures. Antje Vargas from GeoClimaDesign AG presented the modular Geo Standard concept, which is suitable in particular for the serial refurbishing of larger old structures. It involves heating the historic premises by means of heated ceiling slabs. Large room heights are an advantage as they allow unobtrusive installation of an additional built-in ceiling. Tests have shown that users perceive the heat radiating from the ceiling as pleasant and free from draught.

Arched bench

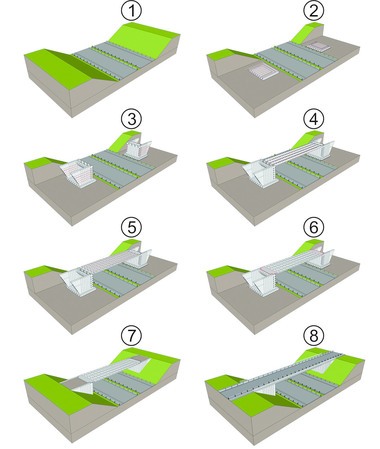

Andreas Borgstädt from Holcim (Deutschland), finally, presented the numerouspossibilities opened up by modular construction with carbon-reinforced concrete elements. He gave numerous examples, such as the bicycle bridge in Winterthur presented on page 92 of the 2022 edition of Jahrbuch Beton Bauteile, which was built using the CPC construction method, as well as case studies on balcony designs that require 80% less material and produce 75% less carbon emissions. He referred to modular bridges in CPC design, which simply need to be plugged together, and finally presented the arched bench created as a demonstrator at Zurich University of Applied Sciences (ZHAW) in the summer of 2022.

In this project, the flat, 24-mm thick concrete slabs were bent to the maximum, yet slowly. The bending process created fine surface cracks, which softened the carbon-reinforced concrete slab and made it possible to narrow the bending radius even further. Neither the load-bearing behavior nor the design life of the component changed thanks to the non-corrosive carbon reinforcement. Two CPC wedges were inserted in a final step to ensure, similar to a bowstring, that the structure remains stable under stress.

Conclusion

The ModularesBauen congress 2022 and the insights gained from it can be aptly described as an analogy to Professor Kuhnhenne’s opening words: “Just as sustainable structures are created by networking construction technologies, sustainable progress is created by networking knowledge.”

Text: Dipl.-Ing. Robert Mehl