Multimodal digital manufacturing for material-efficient concrete components

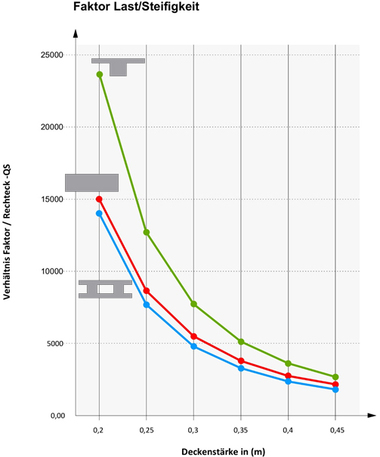

Concrete is the most widely used construction material in the world. Floor slabs in buildings account for approximately 60 % of the concrete volume used in building construction. Current flat slab constructions, with thicknesses of 20-30 cm, are highly resource-intensive and not optimized for CO2 efficiency. Meanwhile, ribbed and waffle slabs are no longer economically feasible with conventional manufacturing methods due to high labor and formwork costs. This paper addresses this issue and explores how automated manufacturing processes can enable the production of lightweight, material-efficient floor slabs with an optimized CO2 footprint. Three innovative multimodal manufacturing methods for slab production are presented:

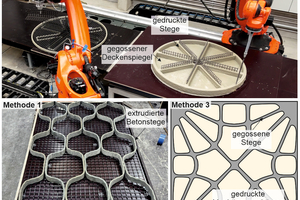

Method (1) facilitates the production of thin-walled sandwich slabs with an internally structured honeycomb core. Carbon-reinforced concrete webs are created using a stationary extruder, shaped into a load adapted geometry, robotically placed into a formwork, and complemented by an upper and lower cover plate. The force transfer between the cover plates and the webs is achieved through a combination of connection reinforcements and profiling of the extruded webs.

The multimodal manufacturing process of method (2) combines the robotic casting of a thin slab with the additive manufacturing (3D concrete printing) of reinforced carbon concrete webs, designed to follow the main moment trajectories. Various ceiling modules are connected through post-tensioned dry joints.

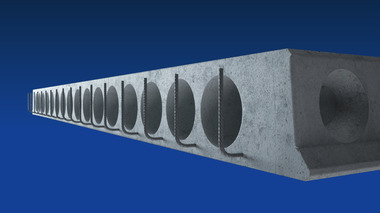

Method (3) involves robotic reinforcement installation, and the additive manufacturing of lightweight displacement bodies made of mineral foam in low-stress areas of the slab. An optimized slab with internal structural efficiency is created through a casting process.

These innovative construction methods reduce the self-weight of the slabs, save materials, and lower CO2-emissions, thereby improving sustainability in the construction industry.