Production of wood-concrete composite floor slabs optimized

The company Brüninghoff, a leading manufacturer of wood-concrete composite floor slabs (WCC floor slabs) in Europe, has further optimized the production process of these elements and is stepping up their marketing for the construction-component market. For this purpose, production capacities at the Heiden location in the German state of North Rhine-Westphalia are being appreciably extended. In future, other general contractors and construction companies, project developers and the craft trades that procure and install the products will also profit from the technical, economic and ecologic advantages of the composite elements. They combine the positive properties of wood and concrete and benefit from the synergy effects of both materials. Stability allowed by shear-groove connectors between concrete and wood structurally provides an extremely strong bond. Here, Brüninghoff orients the production process of the fully prefabricated elements of wood and concrete with a view to consistent sustainability

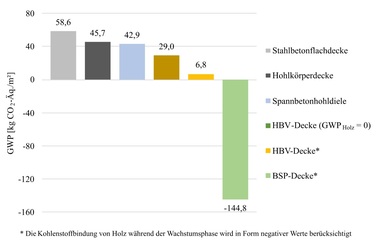

In the manufacture of wood-concrete elements, Brüninghoff actively pursues possibilities for optimized climate-friendly building. The higher-priority objective here is to manufacture the concrete components of the WCC floor slabs as climate-friendly as possible.

Reduced quantity of material and high degree of prefabrication

WCC floor slabs are considerably lighter than conventional reinforced-concrete floor slabs. WCC floor slab elements, compared to pure wood floors, have greater stiffness and inertia – and thus possess enhanced structural performance and sound insulation properties. Basically, production of fully precast elements under protected conditions in the plant ensures uniform high quality standards and optimal use of material. Brüninghoff uses shear connectors to connect the two materials. This is because they ensure effective structural performance – enabling at the same time cost-efficient and fast production. This type of connection is particularly suited for production of precast elements of wood and concrete. Series production – with a very high degree of prefabrication – furthermore generates faster returns for investors, since work times at the construction site are considerably shortened.

Environmentally friendlier concrete formula

In manufacture of the wood-concrete composite floor slabs, Brüninghoff decided on CEM III. With this type of cement, part of the especially climate-damaging cement clinker is replaced with granulated slag – a factor with a positive effect on the eco-balance. In this way, the change from CEM I to CEM III markedly reduces carbon-dioxide emission per cubic meter of concrete. This type of cement produces a lighter color of concrete – at the same time, it is a challenge to precast production, since production in the precasting plant places special demands on early strength. In order to optimize this factor, Brüninghoff changed the concrete formula. In this connection, use of cement per cubic meter concrete was also reduced, which also has positive effects on the entire eco-balance of the elements.

Even if the use of CEM III must be viewed as bridge technology, adaption of the concrete formula demonstrates Brüninghoff’s agility and a consistent orientation aimed at lower processing emissions. In future, at the location in Heiden, now under construction, recycled aggregate will moreover be used for production of floor slabs and, in this way, for floor slabs manufactured with R-concrete. The hybrid specialist is currently working on developing suitable formulas.

In addition, Brüninghoff – against the background of its own sustainability strategy – is considering possible recycling of the WCC floor slab. The hybrid specialist is already working on a type-pure separation of the material combination after end of service life, aimed at returning the construction elements and/or materials to the production cycle to counter resource scarcity.

CONTACT

Brüninghoff GmbH & Co. KG

Industriestr. 14

46359 Heiden/Germany

+49 2867 9739-0