New automated production solutions in concrete construction

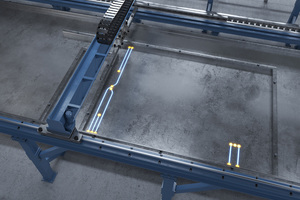

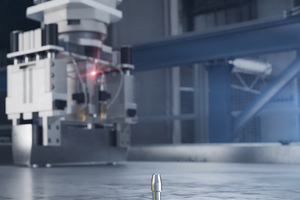

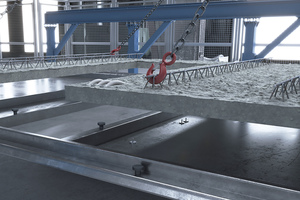

An increasing number of precast concrete plants is using formwork robots to automate production. Kaiser, the leading supplier of innovative electrical installation systems, has now developed bespoke solutions for the electrics to be integrated into this type of factory production. The company‘s new B2 concrete construction programme enables the fully automatic placement of electrical boxes on the positions of the formwork table marked by the plotter according to the CAD data, resulting in increased efficiency in prefabrication.

Innovative magnetic solution

The key feature is the system magnet which, with an adhesive force of 500 N, provides a secure hold for all new B2 one-gang junction boxes, large slab ceiling boxes, end and transition bushes, wall and ceiling transitions and the Halox system for the manufacturer‘s magnet attachment on metal formwork. The complete installation requires only one type of magnet. Four lateral slots ensure precisely positioned placement of the magnet by the gripper of the robot arm and torsion-proof installation of the one-gang junction boxes.

These are all equipped with a special slot for the system magnet. Lamella with stabilising ribs pick up the magnetic pin when the box is positioned and pull it flush onto the formwork for sealing. This ensures a secure fit. Two opposing domes prevent the one-gang junction boxes from twisting and a peripheral sealing lip prevents the ingress of concrete when it is distributed on the formwork table. The magnet can also be removed later with a screwdriver through four lateral openings.

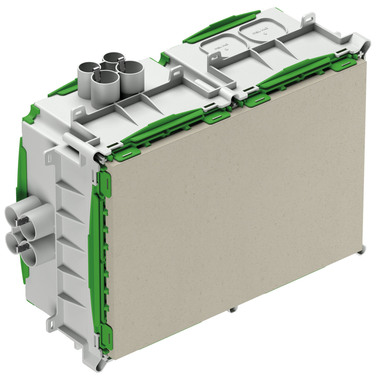

Large one-gang junction boxes

The new B2 one-gang junction boxes are designed as a single square piece for quick positioning and provide plenty of space for terminals and cables thanks to their large volume. Connectors integrated into the side of the boxes enable a torsion-proof and fully insulated combination of multiple boxes at a standardised combination distance of 71 mm. Four screw domes and two expanding claw fields are available for secure fixing of the installation accessories. Special connectors ensure toolless connection of conduits. The one-gang junction boxes are available in sizes 48.5 mm, 68.5 mm and 83.5 mm.

Loadable ceiling boxes

For slab ceilings, the new B2 programme includes the large slab ceiling box 115. In addition to the slot for the system magnet, Kaiser has provided the box, which is available in a diameter of 115 mm, with a quick-release cover that makes it easy to create conduit entries using punch pliers. An undercut on the cover allows the concrete to circulate and, in conjunction with the M5 hook mount, gives the large slab ceiling box a load-bearing capacity of up to 10 kg of luminaire suspension systems. Eight easy-opening options are provided for cable or conduit entries up to 25 mm diameter and four for larger conduit diameters up to 32 mm. This covers 99 percent of all conduit applications.

Solutions for wall and ceiling transitions

For wall and ceiling transitions, the B2 programme offers end and transition bushes and wall and ceiling transitions at 30° angles with reclosable covers and signal brushes for easy location in the concrete surface. They are also equipped with magnetic mounts for a secure and flush hold on steel formwork, but can also be used on wooden side formwork due to their nail domes and large adhesive surfaces. Their solid, lateral snap-in contours enable a secure connection of multiple wall and ceiling transitions.

Time and cost benefits

The products in Kaiser‘s B2 concrete construction system set new standards in precast concrete, ensure precise and flawless electrical installation and bring significant time and cost benefits for the manufacturer, especially in automated production.