New wet-cast plant including coating line installed at concrete manufacturer Bachl

After the hermetic slab press had advanced in age, the Bachl company decided to invest in a wet-cast production line for the manufacture of garden and landscape building products as well as tactile paving systems in order to meet the growing demand by means of state-of-the-art technology.

Karl Bachl GmbH & Co. KG looks back on a long, successful company history: the Bachl company was founded in 1926 in Deching near Röhrnbach in the Bavarian Forest region of Germany. Following the initial production of masonry bricks, the great demand in construction material after the Second World War led to the foundation of the Karl Bachl Ziegel- und Betonwerk oHG in Deching, thus expanding the product range by concrete blocks and brick chippings. Later the company manufactured prestressed concrete beams and terrazzo products additionally. Further concrete factories followed in Hengersberg, Steinerleinbach and Eisenhüttenstadt as well as ready-mixed concrete plants in Regen and Sulzbach, thus the continuous expansion in the field of concrete.

Today, the Bachl group of companies has a workforce of about 2,800 people in Germany and abroad and is considered to be the largest employer in the region. Apart from the major business unit of insulating material and plastics processing as well as the areas of building materials, construction elements and precast concrete production, the construction sector with the areas of building construction and civil engineering, road construction, future house and turnkey industrial and commercial construction still plays a major role in the Bachl group of companies. In the last few years, Karl Bachl GmbH & Co. KG has extended the portfolio by the acquision of several companies such as the Bayerwald Fenster Haustüren GmbH & Co. KG or Metz Forming GmbH & Co. KG.

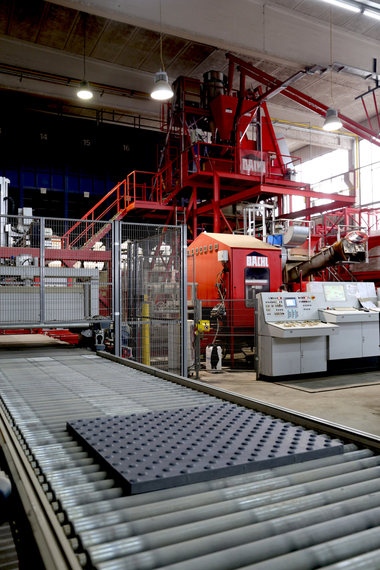

SlabFlex plant supplied by BFS

After the hermetic slab press for the manufacture of concrete products had advanced in age, it was certain for Bachl that they would have to invest in a wet-cast production line. In this regard, Micheal Goldschmidt, manager technical advice tactile paving systems and building materials for garden and landscape construction, stated: „This plant technology is ideal, in particular, as far as our production of garden and landscape building products as well as tactile paving systems is concerned; moreover, the demand is growing continuously. Since May 2016, a SlabFlex line of BFS has been operating at Bachl. The special feature of this plant is that it enables producing slabs having very variable sizes. Dimensions of 20 x 20 cm up to 100 x 100 cm and a maximum construction height of 25 cm are possible.“

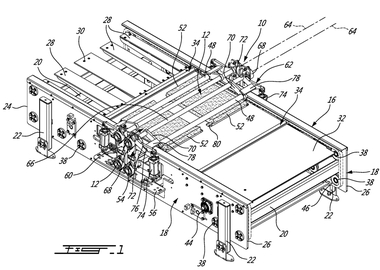

Bachl is working with a semi-automated production line: The production is running fully automated, a forklift deposits the pallet stacks in the buffer and feed stations, whereas removal and packaging are carried out manually. The SlabFlex line includes one concrete metering system, volumetric multi-dose feeding system with automated volume adjustment, release agent spraying system with variable spray nozzle adjustment, vibrating table, automatic demolding system, turning station and mold cleaning station each. Due to the modular design of the SlabFlex, the production line can also be extended by a surface coating system.

Depending on the size of the slabs to be manufactured, the pallets are provided with up to six polyurethane molds in a single- or double-row.

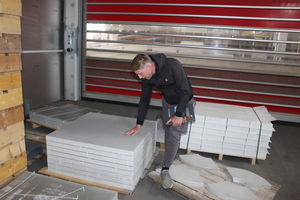

Production boards made by Intexmo

Intexmo GmbH, Ehingen, supplied the molds together with the matching production boards equipped with wooden support frame. „Since we had manufactured a complete solution, Bachl was able to integrate the production boards, including the molds, directly in the production line,“ explained Jürgen Steiger, General Manager of Intexmo. The pallets loaded with molds are automatically destacked on the buffer station and are subsequently carried to the cleaning station by indexing conveyor.

His colleague Jürgen Reiser added: „We supplied the complete production units, i. e. a production unit consists of a stack of 10 production boards including wooden support frame and molds. Our molds allow Bachl to produce patio slabs, swimming pool slabs to all kinds of tactile paving systems as well as bus stop curbstones.“

Patio slabs can be produced in sizes up to 1 x 1 m featuring various wood textures and natural stone surfaces. For the tactile systems all surfaces are CNC milled according to the specifications of Bachl, customized molds for project orders were provided as well. „We are attending Bachl with the wet-cast production line right from the beginning and, of course, carry on offering advice and assistance,“ Jürgen Reiser added. „Moreover, we have developed a raised bed for Bachl, according to the design of Betonista, which can be produced in series. Depending on the product, different polyurethane types are used as well, i. e. of different shore hardness. Automatic production and above all the demolding system have a very gentle effect on the mold which can lead to higher cycle rates.“

Growing trend towards wet-cast production

Products manufactured in a wet-cast process become more and more popular in Germany as well as internationally. „The slabs convince by the faithful reproduction of a natural stone and wooden look. In addition, this method allows the design of extraordinary surface textures. The surface structure achieved in a wet-cast process is much denser compared to stamped concrete products,“ Jürgen Steiger enumerates the advantages. Color requests and color combinations are not limited by this method either, he added. According to the product ordered, Intexmo reproduces the molds in the in-house model-building department based on original samples of stone or wood.

In addition, Intexmo offers product-specific support frames made of wood, aluminum and steel. „Custom-made designs, for example, CNC-milled surfaces or specially designed block geometries are, of course, always possible,“ emphasizes Steiger. The company founders, Thomas Hergöth, Jürgen Reiser and Jürgen Steiger, look back on experience gained over more than ten years in the production of wet-cast molds.

This trend was reflected not least on the well-attended BFT WetCast expert forum held in the Ulm-based Steinbeis-Schule which was continued some months ago, after the successful kick-off event in 2018 (BFT editor‘s note).

Further project partner Remei/BPB/Betra

The Bachl company has been partner of the Remei/BPB/Betra group of companies as regards liquid colors for many years now. Therefore, some joint experience has already been gained, moreover, there have also been repeated points of contact in other areas. Decisive for the cooperation in the major project of wet-cast were rehabilitation works at BPB on the said paved areas. In this process, a potential for optimization was recognized for this product series which, after the implementation, above all is to increase sales and minimize possible complaints.

„In close cooperation with Bachl, we created a project plan and a corresponding optimization concept. It quickly became clear that additional plant equipment was needed, among other things. For such projects, we very much like to cooperate with BM Anlagenbau und Dosiertechnik GmbH located in Hameln, because we can look back again on many years of joint experience,“ explained Dominik Ahrens, the person of contact for Bachl at Remei.

The preliminary tests were carried out at the Dechingen plant in November 2020 and the results were positive, as expected – in response, new plant equipment was ordered and integrated in the production. Since June 2021, wet-cast slabs have been manufactured as well as controlled and monitored by the concrete test center of BPB on a regular basis. „Even after the completion of the project, we continue to work closely with Bachl, as there is always need for action and improvement owing to the large number of shapes and sizes etc.,“ concluded Ahrens.

Cooperation partners wanted for Bachl

Michael Goldschmidt, manager technical advice tactile paving systems and building materials for garden and landscape construction at Bachl, concludes: „Apart from the mentioned project partners, the companies Kniele for mixing technology and Bikotronic for plant control systems were on board as well; of course, our thanks also go to them for the successful implementation of the modernization project. With a production capacity of about 60,000 m² of concrete products per year, in single-shift operation – which does not even reach the maximum capacity utilization yet – we are now excellently positioned for the future.

On this occasion, we would like to refer to the fact that Karl Bachl Betonwerke is currently looking for cooperation partners in the field of tactile paving systems and patio slabs – interested parties are welcome to contact the BFT editorial office or contact us directly.“

CONTACT

Karl Bachl

Betonwerke GmbH & Co. KG

Deching 3

94133 Röhrnbach/Germany

+49 8582 18-0

BFS Betonfertigteilesysteme GmbH

Dr.-Georg-Spohn-Str. 31

89143 Blaubeuren/Germany

+49 7344 9603-0

Intexmo GmbH

Nobelstr. 37

89584 Ehingen/Germany

+49 7391 75260-00

BM Anlagenbau und Dosiertechnik GmbH

Werftstr. 11

31789 Hameln/Germany

Remei Blomberg Gmbh & Co. KG

Industriestr. 19

32825 Blomberg/Germany

+49 5235 963-0