On course for the future with ultra-modern precision formwork

B+S Engineering GmbH specializes in the production of molds and machines for the precast concrete industry and supplies plants all over the world. After the eight-month rebuild phase and the associated investment of 1.6 million euros in a larger and more flexible milling machine, the company is still on course for the future.

The worldwide demand for production equipment for the manufacture of precast concrete elements such as poles for high- and low-voltage power lines, tower segments for wind turbines and cable shafts is constantly increasing. B+S Engineering GmbH, based in Rheine-Kanalhafen, specializes in the manufacture of molds and machines for the precast concrete industry and supplies concrete plants all over the world. After the eight-month rebuilding phase and the associated investment of 1.6 million euros in a larger and more flexible milling machine, Managing Director Stephan Sehliger has put his company further on course for the future.

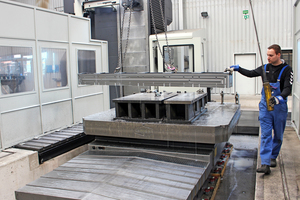

The much larger milling machine is a multi-tasker; milling and turning on one machine. With a machining volume of 10.0 x 3.0 x 1.5 m, a fully automatic milling head changing system and the possibility of pendulum machining, the milling machine not only expands the performance spectrum of the B+S company, but also ensures more flexibility and productivity. Its commissioning was duly celebrated, for which Managing Director Stephan Sehliger had invited his 55 employees and project participants to an official inauguration in March. Mayor Peter Lüttmann also accepted the invitation, praised „the investment in the future“ in his speech and cut the opening ribbon. This was followed by a short demonstration of the new machine by cutting machine operator Nico Evers.

„This investment is trend-setting for our company, and for the operation of such a high-tech plant, skilled workers such as well-trained cutting machine operators are certainly still to be recruited,“ commented Managing Director Sehliger.

High accuracy and precise positioning

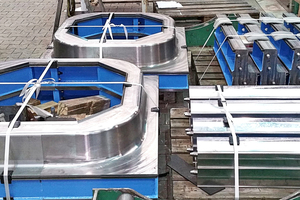

Quality and precision are decisive features that have an impact on production times, costs and sales prices. Production of precision concrete components not only requires appropriate production equipment. A decisive factor here is the tightness of the formwork. Tight manufacturing tolerances in the production of the formwork lead to a high fitting accuracy of the sealing elements and prevent the escape of fine particles from the formwork. Likewise, the joints of the concrete parts are very precisely formed, which greatly simplifies the subsequent assembly of the finished parts on the construction site.

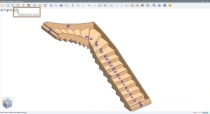

Components up to a volume of 10.00 x 3.00 x 1.50 m can be machined on the new milling machine - and without this mechanical machining, the tolerances could not be permanently guaranteed. B+S has a strong presence in this segment and has developed its own design based on solidly manufactured welded assemblies with subsequent mechanical processing. The formwork segments are correspondingly accurate - and permanently so.

The formwork segments fit together exactly, even when several formwork segments are combined. This is why the tight manufacturing tolerances are so immensely important and can only be achieved by mechanical processing. The accuracy of the formwork prevents bleeding of the concrete at the formwork interfaces and thus reduces rework on the stripped product.

Betonelemente Schmidt in Bad Salzschlirf in Upper Hesse produces with several B+S panel formwork systems, which are designed as a modular system in order to be able to reproduce different dimensions. The precision and flexibility are a decisive key to the success of the company from the district of Fulda. The general high accuracy of the frame elements and precise positioning of the sealing elements on the spigot end ensure trouble-free assembly on the construction site.

Wide range of applications

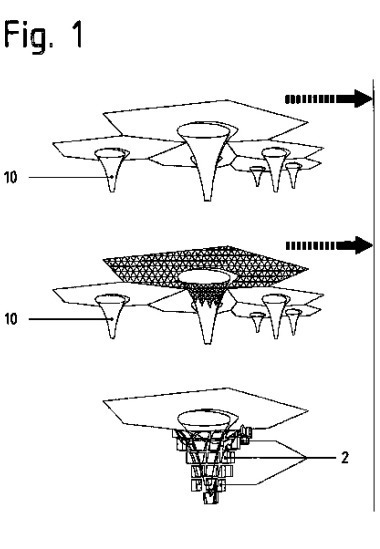

New quality standards in the production of frame-shaped precast concrete elements can secure the future of companies and employees. The variance of framed concrete products is constantly increasing and there is a wide range of possible applications.

The following are some examples on framed precast concrete products:

Frame elements: From history, frame elements are known for use in civil engineering. Due to the increased heavy rainfall events, these very frame elements are also increasingly used for stormwater retention.

Concrete tanks: Water is one of the most important resources of our earth and it is necessary to protect the groundwater. In many countries, it is now a requirement that stormwater catchment tanks be used in new construction.

Elevator and fire protection shafts: In the past, these components were usually cast in place concrete. Now, these elements are also available as precast elements to shorten local construction times and increase the safety of new buildings.

Room modules: Affordable housing is currently a hot topic in all countries, and there are now various systems on the market as precast concrete elements that are very economical and sustainable.

Waste collection containers: very intelligent separation systems can now be found in many apartment blocks, in public spaces and along highways to make disposal effective.

Transformer Stations: In the age of electrification, the need for transformer stations has increased tremendously.

Bicycle garages: concrete bicycle garages with intelligent locking systems offer improved protection against theft and protect bicycles from the elements.

„We focus on quality and precision to ensure our customers‘ success. To this end, we have invested heavily in recent years - in October 2022, our fourth CNC milling machine already went into operation. We are therefore ideally equipped for the future,“ concludes Dipl.-Wirtsch.-Ing. (industrial engineer) Stephan Sehliger.