GFRC-elements for the New Chancellor Square in Bonn

The Wasa Construct division is gaining in importance within the Wasa group. Only small formats were manufactured in the first years of polyurethane mold production, but now the share of large molds for façade construction is increasing. For the last seven years, Wasa has been involved in major projects, where the interaction of modern technology and professional skills was essential. By constructing the New Chancellor Square in Bonn, Wasa has proven their talent in the field of mold making once again.

The new Chancellor Square, combines innovations from a wide variety of fields. Futuristic architecture encounters modern building materials – sophisticated detailed solutions facilitated with expertise from Wasa. The construction project, which is managed by the Art-Invest Real Estate project development company, sets new standards for Bonn and the region. With its high point of 101,5 m, the New Chancellor Square forms a fresh landmark in the middle of the city quarter. Only the Post Tower and the Langen Eugen in the former government quarter, close to the New Chancellor Square, will still outgrow the building in height.

House 2 is nearing completion. Construction work on houses 1 and 3 is also already well advanced. Lift rails, portals and cabins have been installed for the shell structures to be accessible. After their final completion in 2022, the 28 stories of the tower and two other building areas will offer modern office solutions, areas for gastronomy and retail, as well as event and conference areas. The New Chancellor Square will consist of three building structures grouped around a large public square, offering a characteristic landmark to Bonn’s skyline.

12 casting models and 30 PU matrices

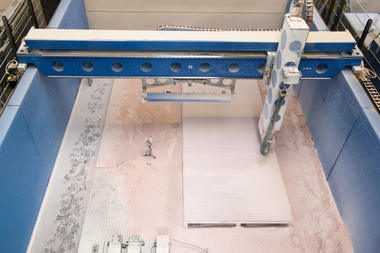

The Lindner Group, based in Arnstorf, Bavaria, commissioned Wasa to produce 12 different casting models, of which 30 PU matrices were made with their corresponding production frames. The dimensions of the matrices are considerable. The longest model measures 11.0 m in length; the corresponding PU matrix weighs 240 kg. Glass-fiber reinforced concrete elements, were produced on the matrices supplied by Wasa. The façade will consist of a total of 2,786 GFRC elements.

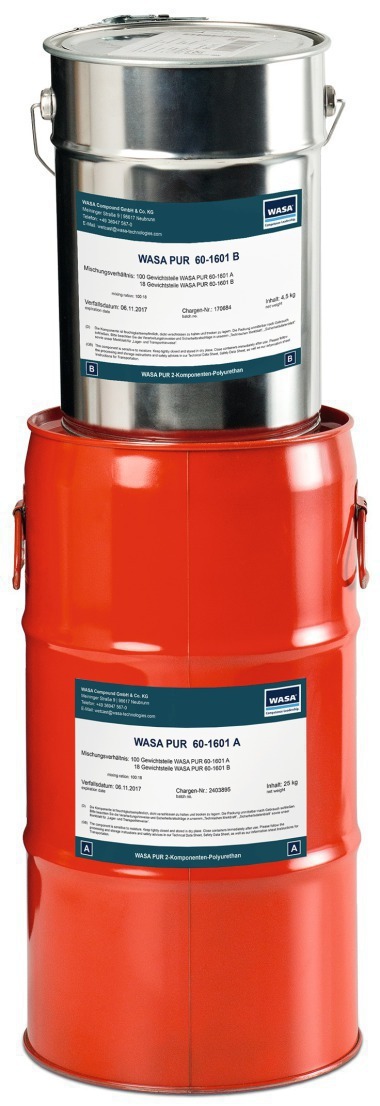

The great efficiency with which Wasa operates is also reflected by the short time required for production, which only took two months: order placed in mid-June 2020, delivery already mid-August 2020. All the milled components, needed for the production frames and casting models, were able to be manufactured on a modern, 5-axis milling machine. Without this investment, which Wasa made at the end of 2019, it would have been impossible to meet the delivery date required by the Lindner Group. Several hundred façade elements were produced on some of the formwork during the construction work. The first and last elements to be installed had do have the same surface finish and identical geometry – a major challenge for Wasa Pur PU system, which has once again proven its worth by this major project. Two-component casting resin was easy to process, due to its low viscosity with the associated flow properties, a long pot life and the smooth surfaces.

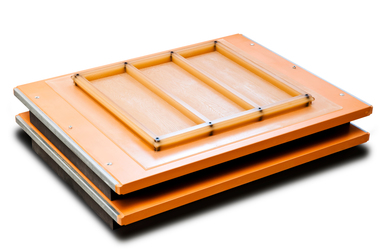

Wasa Shuttering

Another innovation ensures rapid progress: Wasa Shuttering – a method that was specially designed and developed for producing flat concrete products and for which a utility model application has been filed by Wasa. Among other things, this process eliminates the need for time-consuming silicone work to seal formwork and form chamfers. This generates savings on both material resources and working time. Wasa Shuttering ensures a uniform joint pattern, the geometry of which can be individually adapted to a customer’s wishes. The shaping of the chamfer pattern on the precast concrete components is also unproblematically reproducible in large quantities.

The façade of the New Chancellor Square is the latest in a growing list of major projects undertaken by Wasa – proof of its great innovative strength and high quality.