Practical tips for thin-brick-embedded precast façades elements

One of the architectural trends in building construction in recent years has been and continues to be façades with brick surfaces. While in certain regions brick wall and façade surfaces are an everyday traditional construction method, it is discernible that thin clay brick embedded precast concrete façade elements are gaining importance also nationwide, whether designed as panels or as a sandwich element. Hence, more precast concrete plants are dealing with this surface finish.

There are many reasons for this, including the variety of design options and the robustness of the surface. Assuming that in the future sustainability and acceptance considerations may make it even more important to offer alternatives in terms of a building´s visible outer skin, brick surfaces represent an important option for precast concrete manufacturers.

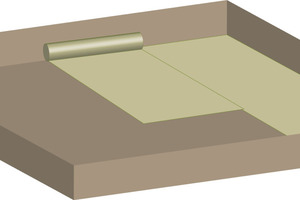

Retarder paper as mould inlay and contact zone

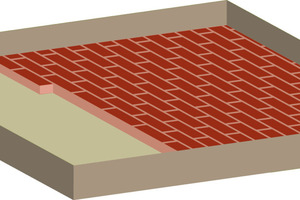

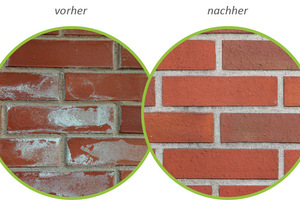

However, when designed as a precast concrete surface there are some challenges in terms of craftsmanship when placing or fixing the thin brick in the correct position on the mould surface before the mould is filled with concrete. Various aids are available for this purpose (wooden strips, joint tapes, formliners etc.), but it must be taken into account that the bricks have size tolerances due to the manufacturing process. Also, it is almost impossible to prevent cement paste from seeping through along the sides and towards the surface of the brick to harden there. Since the surfaces of the brick are often rough and to a certain extent absorbent, this contamination can usually only be removed with considerable cleaning effort.

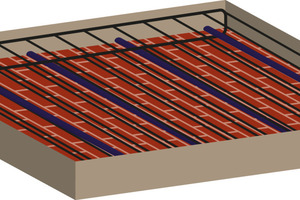

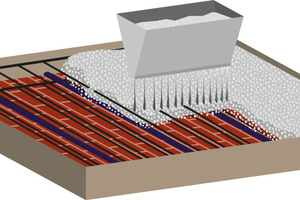

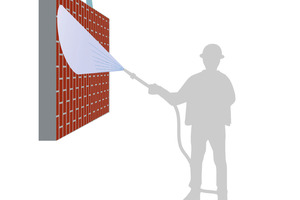

To simplify this cleaning procedure, experienced precast concrete plants use paper coated with a surface retarder (also known as exposed aggregate concrete retarder paper) as an intermediate layer and contact zone in between the mould and the brick surface. Therefore, the cement paste that reaches the surface of the brick cannot harden there and is simply removed with a water jet after demoulding the precast element. See Fig. 1 to Fig. 6 (Highly simplified graphic representation - detailed description available at www.hebau.de. All graphics are protected by copyright).

Long-term observations pay off

When using formliners made of polyurethane or similar, in which the design pattern and the positioning of each brick are represented by the corresponding formliner texure, it is possible to work with cut-to-size retarder paper strips. If there are considerable size tolerances of the brick, a thin stretchable cloth can be treated with a liquid surface deactivator before using this as the intermediate layer between the formliner and the brick surface. If no such stretchable cloth is available, a surface deactivator (to be determined in a preliminary test) can also be applied directly to the formliner or brick surface.

Marcus Herrfeld, managing director at Hebau explains that, „Our observations over many years have shown that only certain surface deactivators (also called exposed aggregate surface retarders) are suitable for the mould surface materials, do not affect adjacent mould parts, and leave a near sterile brick surface that is also suitable for subsequent surface protection products such as anti-graffiti coatings. Therefore, expert consultation is recommended.”