Radar technology: an alternative for determining material moisture in sand, gravel, concrete and surfaces

Imko develops and produces moisture-measuring technology for a large variety of applications

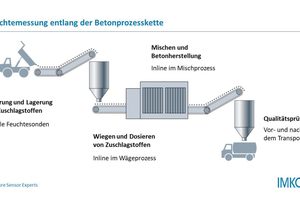

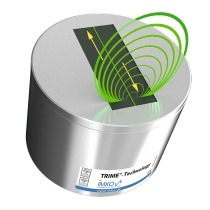

in construction, soil and bulk solids since 1984. Their most prominent solutions are the instrumentations of the entire process chain of concrete production. Based on the revolutionary Trime radar technology, the measurement of water content is enabled with high precision in challenging processes: without measurement drift, caused by wear. This sounds highly complicated, but the exact opposite is the case. Trime technology deploys a radar-signal through the device, resulting in a defined measuring field at a sensor. This measuring field is geometrically constant and measures all water within this field. Water molecules are dipoles and are aligned in the electric field, which consumes energy. Trime measures this fact with highest precision.

In the past 40 years Imko has improved measurement and calibration. The sensor reliably measures gravel, sand and crushed stone up to 32 mm, as well as other aggregates. Calibration curves for all conventional types of aggregates are stored in the standard settings of the probe (plug and play). Wear and abrasion do not influence the measurement principle. Recalibration at periodic intervals is not necessary. As an option, carbide steel surfaces delay and/or prevent early wear on the sensor and definitely extend its lifetime. The sensors are compatible with all conventional control systems and are easy to set up and commission. Using the same technology with various sensors, Imko performs mobile measurements in sand and aggregate at delivery or storage, or during batching underneath the silo hatch. More durable sensors are used inside mixers. At the job sites, Imko also measures water contents in various applications. The determination of the w/c ratio is the most common one and even moisture contents within finished flooring can be realized. All of the above stated enables process control and documentation through delivery and finishing in uniform quality as required more and more in several regions. This makes measuring fun as Imko states: “measure with pleasure.”