Soest building construction specialist delivered 900 precast elements

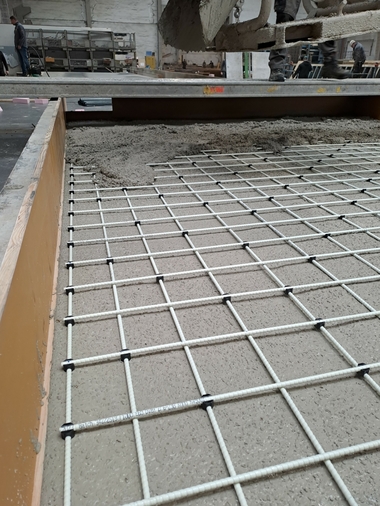

Following the demolition of the former department store Dieler in Menden in the German state of North Rhine-Westphalia, the newbuild presents a challenge in terms of material logistics and construction-site management. In the center of the building, the company J. Lehde GmbH from Soest, Germany, has set up a revolving tower crane that can lift loads of up to 20 tons. This arrangement enables installation of the precast reinforced-concrete elements: in particular, columns, wall panels, floor slabs, joists and stairs. Fast-track construction is typical for building with precast reinforced-concrete elements, since the elements are manufactured ahead in Soest and delivered just-in-time by truck.

Timing at the construction site is especially important here, since only the Gartenstrasse is available as storage place for the material. Martin Butz, Managing Director at Lehde, explains: “We share the storage and work space at Gartenstrasse with the building-shell constructor and the other trades that will sooner or later go into the building. That can be rather tricky.”

Precast elements guarantee fast construction progress

Despite these difficulties, Lehde was able to complete the lower floor within only five weeks. Completion of the remaining floors will take approx. three weeks each. The speed of construction, in addition to excellent fire protection, is another advantage when building with precast reinforced-concrete elements. In-situ construction, in the company’s own estimate, would take much longer than the currently planned end of construction on 31 December 2024.

Lehde’s top slewing crane will be removed, part for part, from the central opening of the building shortly before project completion. For this purpose, according to the construction schedule, Lehde will need a 400-ton, truck-mounted crane in March 2024. “We have proceeded like this for previous projects: for example, for construction of the Kress building in Soest,” declares Butz. Logistics is likewise part of the daily project routine for Lehde : “We know exactly which part is produced in the plant on which day. On that day it must be delivered by truck to the construction site in Menden and immediately connected to the other parts. Everyone there has digital support.”

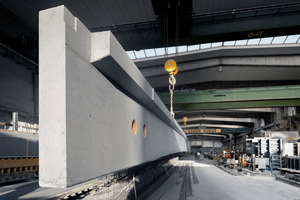

The former Dieler House in the lower city area of Menden had stood empty for years. Decades ago, the retail company Küster had occupied the building. Not least for that reason, the investment company Siepmann founded the company Geschäftshaus Küster GmbH for the construction project. Lehde delivered around 900 precast reinforced-concrete elements (approx. 4,000 tons) for the four-story building: 140 columns (up to 9.50 m length and weighing up to 6.5 tons), 184 joists (up to 9 m length and weighing up to 9.1 tons), 332 floor slabs (up to 9.50 length, 2.57 m width and up to a weight of 7 tons) as well as 242 wall panels (up to 9.39 m length, up to a height of 3.94 m and weighing up to 19.25 tons). The contract volume, for the Soest building construction specialist alone, ranges at around 3 million euros.