Sophisticated engineering skills and creative

concrete design: Allplan software in use in France

Construction contractors and architectural firms are increasingly discovering the room for creativity and aesthetic appeal that concrete has to offer. French company Société de Préfabrication de Landaul (SPL) specializes in precast walls and operates two state-of-the-art precast factories and two design offices. SPL relies on Allplan Precast for designing precast elements used in out-of-the-ordinary projects. This article presents two project-specific applications of the design software: the “Identity” building complex in Rennes and the “Talards” residential development in St. Malo, France.

Inclined walls made of precast elements: the “Identity” building complex

The “Identity” complex of buildings located in Rennes, France, is an extraordinary architectural masterpiece. Architecture firm Blanchard Marsault Pondevie designed “Identity” as a crystal geode composed of three interconnected rock sections.

A silver aluminum mesh encloses the three parts of the building and interlinks the roofs and façades in a filigree manner by creating a silver thread. In the upper part, the cladding of “Identity 2” consists of very narrow diamond shapes to offer the greatest possible protection from the sun. In the lower part, however, the large-mesh structure allows a generous amount of daylight to enter. The three “Identity” buildings are designed to form the EuroRennes business district near the new central station. “Identity 2” accommodates offices, retail stores, and a movie theater.

Flexibility, precision, and innovation

One of the specific features of the “Identity 2” project are its inclined walls, which lend a unique appearance to the building. Société de Préfabrication de Landaul (SPL) was commissioned with designing and producing these sloping elements.

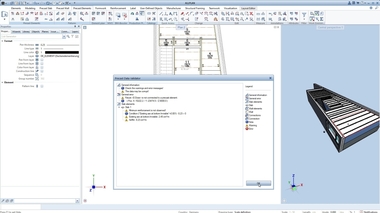

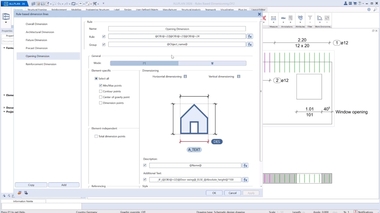

SPL specializes in precast walls and operates two state-of-the-art precast factories and two design offices. For precast design, SPL relies entirely on its tried-and-tested solution, Allplan Precast, which enables the highly automated design and production of precast walls.

The “Identity” project was the first of its kind for SPL because inclined walls were designed and manufactured for the first time in the history of the business. SPL takes pride in having delivered all prefabricated elements covering a total area of 800 m² to the highest quality standard and on time. The project took just one year from design to installation of the walls.

Precast elements form an extraordinary façade: the “Talards” residential development

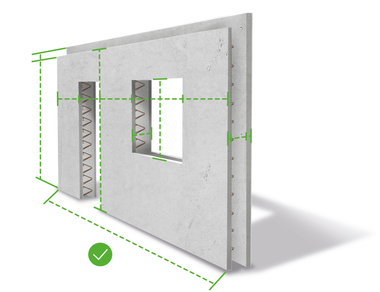

Concrete comes to the fore whenever it is exposed to give buildings a spectacular appearance that people remember for a long time. The “Talards” residential development in St. Malo, France, clearly demonstrates how textured form liners can be used to design façades in a creative manner. The building ingeniously combines architectural design freedom with the efficiency of precast.

French company Société de Préfabrication de Landaul (SPL) was commissioned with designing and producing the walls using textured form liners. SPL specializes in precast walls and operates two state-of-the-art precast factories and two design offices in Landaul and Rennes. For precast design, SPL relies entirely on its tried-and-tested solution, Allplan Precast, the CAD software for precast design and construction supplied by Allplan.

Design variety and efficiency

Elastic textured form liners were used for the “Talards” complex of residential buildings located in the French region of Brittany. SPL used such form liners to manufacture the textured prefabricated walls at the precast plant. One of the challenges that “Talards” posed regarding the textured form liners was that the project site is located in the immediate vicinity of the sea, exposing it to the harsh oceanic climate. This meant that particularly thick form liners had to be used due to the salty air and constantly high humidity.

Design challenge mastered

In addition, aligning the vertical joints and the textured form liners between the levels was exceedingly demanding for the design team. However, the team members mastered this challenge, too, thanks to the numerous automated workflows and processes integrated in Allplan Precast. In total, SPL designed and produced 490 m² of precast walls for the building comprising 33 residential units spread across the ground floor and five levels on top of it. The design of the walls took six months to complete, while their installation required another four months.

CONTACT

Société de Préfabrication de Landaul

ZI de la Gare Ouest

56690 Landaul/France

+33 2 97 59 49 50

Allplan Software Engineering GmbH

Urstein Süd 19/1/6

5412 Puch b. Hallein/Austria

+43 6245 21001-0