Successful extension of the laboratory building at Meier Betonwerke

The new laboratory cube at the precast plant Meier Betonwerke in Lauterhofen, in Bavaria near Nuremberg, is 23 m long, 10 m wide and 4.25 m high. Insiders know that this rather inconspicuous one-story building is the treasure chest on the company grounds, because the traditional company in southeast Germany is researching there for the future.

But, early in planning, mundane requirements demanded consideration. The company needed space for the measuring and test equipment, as well as storage facilities and additional workplaces. And for the stated goal of “further development with future prospects,” as desired by the company management, it was necessary to once again extend in detail the basically simple design requirements.

Now, since the summer of 2022, up to three laboratory technicians work at the same time in the new building of the Syspro member company. Their tasks include further development of prototypes, updating of formulas and of quality assurance for concrete, steel and all system products that the family-run company has been offering and producing in its history of over 140 years.

Attractive workplaces

“Concrete lab” the staff call the cube with its separate inner hall, the narrow corridors and the social area filled to the brim with high tech that adjoins the previously used laboratory rooms of Meier Betonwerke. “With this extension, we not only wanted to equip new workplaces, but also to make the creative and technical possibilities of our concrete construction elements tangible to enable us to present potential customers with approaches to sustainable solutions,” says Dietmar Melchner, the company’s Head of Sales, as he explains the project with an investment volume of around 480,000 euros.

With self-sufficient energy supply

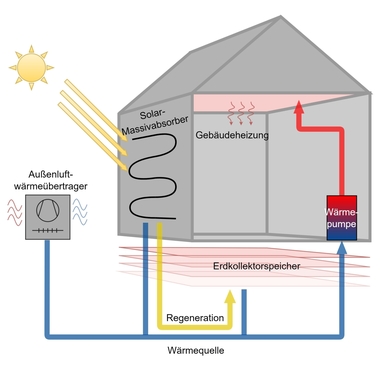

Although rather reserved in outward appearance, the concrete laboratory shines with inner values. The one-story building, designed by the architect Florian Schabner, supplies itself with electricity and heat from renewable energies and with specifically coordinated building services.

A photovoltaic system with an output of 17 kWp on the roof and a heat pump with ground collectors on an area of 200 m², are essential elements of energy self-sufficiency here. An air-heating pump from the manufacturer Hautec supplements this equipment, and an outside loop embedded in the thermal walls collects additional solar energy over an area of around 20 m², and serves to feed in additional heat.

Innovation through combination

“Planning of the building shell with thermo walls, and the HVAC floor slabs with integrated pipe registers for cooling or heating the rooms, satisfied the basic requirements for creating this climate-neutral building,” explains Dietmar Melchner.

Individually considered, all of the technologies used are technically mature, explains Melchner. But the special innovation potential of the building lies in the coordinated interplay of the various heat and energy sources and in the combination of HVAC floor slabs in the cooling mode. “In addition, new development of a special control system was necessary for the outside loop embedded in the thermo wall,” continues Dietmar Melchner.

The entire heat and energy technology in the building is also part of a research project. Scientific development by the Department Technical Systems, Processes and Communication – headed by Prof. Dr. Christian Schweigler at the University of Applied Sciences in Munich – was already implemented in the planning phase and is supported with continuous measuring by cast-in sensors throughout the building structure.

With this documentation, the technical staff of Meier Betonwerke would like to further develop their products. “But we are already quite satisfied with the results gained to date. The new building demonstrates that our thermal walls and HVAC floor slabs are especially efficient and future-viable in intelligent combination with other technologies,” is Dietmar Melchner’s summary until now regarding the equipment in this particularly sustainable reference project.

CONTACT

Syspro-Gruppe Betonbauteile e. V.

Matthias-Grünewald-Str. 1-3

53175 Bonn/Germany

+49 228 37756322