Syspro member Lütkenhaus drives optimization with

innovative air-handling ceilings

In spring 2024, construction contractor Heitfeld will move into its new head office in Waltrop. The company is currently constructing a four-story building with a total project investment of about 5 million euros on a previously unused brownfield site at the company’s premises in the northern Ruhr region.

“Environmental and cost aspects have caused the entire real estate industry to shift its mindset in recent years,” explains Heitfeld CEO Pascal Busch, whose company has been doing business throughout the Ruhr region for more than 120 years. Heitfeld offers shell and turnkey construction services to a wide range of residential and commercial clients.

Floor space for offices, medical facilities and gym

The “Zur Pannhütt 31” project named after the property’s street address includes up to eleven office and commercial units starting from 100 m² on a total floor space of more than 3,000 m². In addition to conventionally designed offices, some of which Heitfeld will occupy itself, large workspaces are planned for leasing to other businesses, while the individual floors extending over an area of up to 900 m² are designed to also accommodate medical facilities as well as doctors’ practices and a gym.

Getting rid of fossil fuels

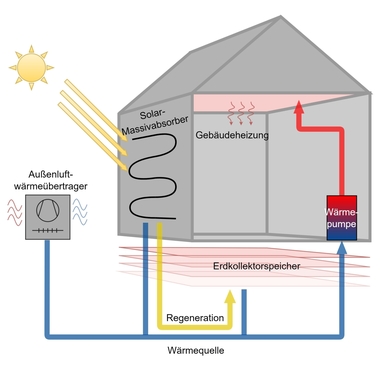

State-of-the-art, highly efficient thermal insulation ensures that the entire building will meet the requirements of the KfW 40 Efficiency House standard. A photovoltaic system with a generation output of approximately 90 kWp will be installed on the roof, and heating and cooling will also be provided by geothermal energy and air-source heat pumps. As a result, the Pannhütt 31 building can be heated completely without fossil fuels.

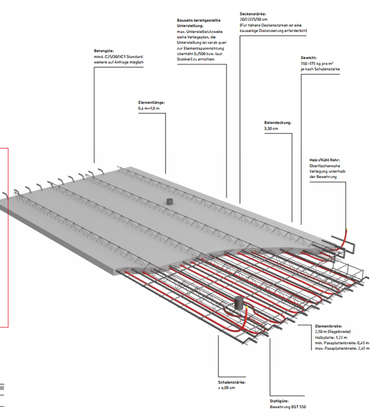

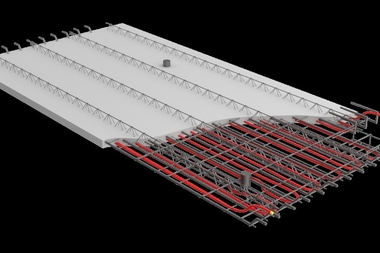

B. Lütkenhaus GmbH supplied extensive component-activated ceilings for the ground, upper and attic floors that are particularly effective for heating and cooling purposes. “Overall, we delivered 3,700 m² of prefabricated ceiling elements to the site during the 2022/23 winter season. 2,700 m² of these ceilings are equipped with the oBKT technology (oberflächennahe Betonkerntemperierung; near-surface concrete core activation). In addition, 1,000 m² of interior thermal wall panels from our production were installed,” reports Dirk Spielbrink, authorized representative and head of costing at the precast plant operated by the Syspro member.

Flexibly controlled heat registers integrated in ceilings

The heat registers integrated in the shells of the precast ceilings are placed much closer to the surface compared to conventional cast-in-place concrete air-handling ceilings, which enables even more efficient adjustment of heating and cooling outputs. While the conventional design uses the mass of the concrete components as a heat reservoir, air-handling ceilings equipped with the oBKT technology ensure much shorter ramp-up times. This type of fit-out thus makes it possible to heat individual rooms and usable floor spaces more quickly and separately from each other.

The proprietary technology named “LTKH-Klimadecke” (LTKH air-handling ceiling) developed by B. Lütkenhaus GmbH provides the option of reducing heating temperatures by up to 2°C. According to Rehau, the heat register manufacturer whose components were installed, energy consumption can be lowered by 6 to 12% as a result.

“This is one of the variants and continuous improvements of this air-handling ceiling that the Syspro member companies offer. In keeping with the spirit of our association, our members are continuously working on refining this technology. Lütkenhaus has developed a very interesting design that further optimizes the energy-saving potential of our product,” explains Syspro Managing Director, Dr. Thomas Kranzler.

The architects and engineers at Heitfeld focused not only on the obvious energy efficiency gains but also on the rapid construction progress that could be achieved thanks to the simple and flexible installation of precast components. The elements were delivered over a short distance from the Dülmen precast plant, which is located only 30 kilometers away from the job site.

CONTACT

Syspro-Gruppe Betonbauteile e. V.

Matthias-Grünewald-Str. 1-3

53175 Bonn/Germany

+49 228 37756322