Sustainable reinforcing steel with a clear carbon footprint

The construction sector is confronted with strict environmental constraints and with increasing pressure to reduce CO₂ emissions. The company Sülzle Stahlpartner offers a climate-friendly solution with the sustainable reinforcing steel Stoox PCF. This approach reveals the actual CO₂ carbon footprint with clear limit values for reducing CO₂ emissions in construction projects.

In the face of our acute climate change, Sülzle is pursuing a global approach toward sustainability. This is reflected in the corporate philosophy of the family-owned company Sülzle and in products such as the sustainable reinforcing steel Stoox. “With Stoox, we are pushing the development of sustainable reinforcement solutions and provide our customers with the possibility of demonstrably reducing the carbon footprint,” as emphasized by Heinrich Sülzle, Managing Partner of the Sülzle Group.

The special feature of Stoox PCF Steel: The entire process for determining the carbon footprint (product carbon footprint, PCF) has been validated by the German TÜV. This renders the environmental impact of reinforcing steel over the entire delivery chain more transparent than ever before. Digital processes in production make it possible to trace the derivation of the reinforcing steel and, accordingly, to determine a specific footprint.

With Stoox PCF Steel, Sülzle Stahlpartner uses advanced electric steel production for the greater part of production of its reinforcing steel. This steel is clearly more environmentally friendly than steel from conventional blast-furnace production. Conventionally, scrap steel instead of pig iron is melted, which accordingly attains a recycling rate of approx. 90 percent. Stoox PCF steel therefore represents a model for practical implementation of the circular economy in the construction sector.

Flexible through three product variants

Sülzle offers three variants of reinforcing steel for the various market and customer requirements. For Stoox PCF Steel, precise evidence of the PCF of the reinforcing steel can be provided by digital production technologies for batch tracing and by the TÜV-validated calculation method. Based on this knowledge, the specific carbon footprint of the reinforcing steel can be documented for subsequent analysis.

With the product variant Stoox PCF Limited, Sülzle guarantees adherence to a specific carbon limit value through additional control of procurement and production processes, averaged over the project term. In this way, reinforcing steel can be used as a significant lever for enhancing the climate balance of a construction project, as early as in the planning phase.

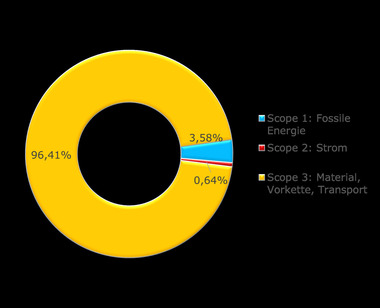

With Stoox PCF Premium, the system boundary of determining the carbon footprint can be extended beyond the production of reinforcing steel. Sülzle includes, in addition, its transport as well as its further processing. The PCF is thus documented up to its arrival on the construction site.

Proven in practice

The practicability of Stoox has already been proven: Sülzle – commissioned by the joint venture ARGE U5 consisting of Ed. Züblin AG and Wayss & Freytag Ingenieurbau AG – delivered sustainable steel for construction of the U5 underground rapid-transit line in Hamburg. This steel has an average carbon footprint of less than 400 kg carbon per ton. Accordingly, Sülzle had – one year earlier than planned – already clearly fallen below the original goal of less than 500 kg of carbon per ton of steel. This is part of the comprehensive sustainability strategy of the Hochbahn U5 Projekt GmbH, which had aimed for a reduction of 70 % in the conventional carbon emissions resulting from construction of the U5 underground rail line. As a result, this represented implementation for the first time of a comprehensive carbon reduction strategy for a rapid-transit infrastructure project in Germany.

In summary: Architects, investors, structural engineers, developers, precast plants and construction companies can integrate the reinforcing steel Stoox in an environmentally friendly and effective manner in their projects. “Our vision is clear: we want to play an active part – already in the early planning phase – in shaping sustainability and in acting as a reliable partner for environmentally friendly reinforcement solutions,” explains Heinrich Sülzle. The reason for our commitment lies in the deep conviction of our family enterprise, which has been active for 145 years and is now in its fourth generation: that sustainability must be an integral part of the company’s vision in order to be successful over the long term and to be able to make a positive contribution for coming generations.

CONTACT

Sülzle Holding GmbH & Co. KG

Hauffstraße 14+15

72348 Rosenfeld/Germany

+ 49 7428 9414-0