Component activation using precast wall panels or floor slabs

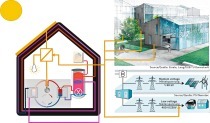

Heating and cooling buildings all year round using renewable energy – this is what the innovative system of thermal component activation based on precast elements can achieve. This system works according to a simple principle: Tubes are installed in the floor slab or wall panel and gently heated to a surface temperature of approximately 26°C. The ceiling radiates this energy into the room. Objects or bodies will be heated wherever the heat waves hit them. Due to their design, standard radiators emit only a small portion of the heat as radiant heat; the major portion of it is emitted into the air. The warm air rises and colder air flows in, increasing the energy demand.

Cooling rooms using component-activated ceilings uses the same principle as heating, except that water colder than the room temperature passes through the tubes. The objects in the room transfer their energy to the cold ceiling. Component-activated buildings thus require significantly less energy for heating and cooling than those equipped with conventional heating and cooling technologies. The lowest environmental impact is achieved in combination with renewable energy sources: Smart thermostats call up heating or cooling energy whenever it is available cheaply from renewable sources in the grid. Current weather forecasts can be considered in this process.

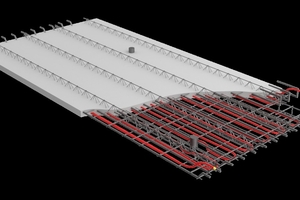

To maximize the potential of thermal component activation, the tubes should ideally be designed and installed in the precast elements at the factory. It is possible to insert them into the formwork either mechanically or by hand: The precast element will be poured immediately after attaching them to the reinforcement. After installation, the individual tube connectors are coupled, and the elements are connected to the manifold. This eliminates the risk of damage to the tubes caused by on-site placing of reinforcement or installing embedded components such as electrical conduits.