Teka equips four CRP plants with turbine mixers

Within just four years – from 2018 to 2022 – the total production capacity for precast products was to be increased fivefold: This was the goal set by French precast business CRP. For this purpose, two new plants, including a twin production facility, were built in record time and the two existing plants were modernized with Teka turbine mixers.

Latest-generation Teka turbine mixers

Within just four years – from 2018 to 2022 – the total production capacity for precast products was to be increased fivefold: This was the goal set by French precast business CRP. The company specializes in the manufacture of products for civil engineering. To keep up with the strong sales growth recorded for almost a decade, CRP is bound to invest considerable amounts in its production sites. To achieve this goal, the quantity of concrete produced per day also needed to be increased by the same amount. CRP thus built two new plants, including a twin production facility, in record time and modernized the two existing plants. The company decided to equip all sites with the latest generation of Teka turbine mixers.

CRP: From regional SME to nationwide market leader

As an independent, family-run industrial company, CRP is located in the heart of rural France. In recent years, CRP has been able to turn what at first sight appears to be an unfavorable geographical location – far away from major conurbations and centers of economic activity – to its advantage.

The French town of Brive is located at the junction of two highways that extend through the country in the north-south and east-west directions. This is where CRP created a real logistics hub, marketing its products throughout France and in parts of Belgium. Over time, numerous merchants specializing in the distribution of precast products for civil engineering have entrusted CRP with the delivery of the products they demand. The company currently supplies a steadily growing network of about 600 merchant sites on a daily basis; it has thus become the third largest French manufacturer of civil engineering products in record time.

This was possible only because CRP offers an exceedingly wide product range, which essentially comprises four segments: stormwater drainage, sewers, utility networks and urban roads. Over the past four years, the company has invested more than 35 million euros in new production facilities. It currently operates five plants, four of which have just been built with an unprecedented level of automation. The newest site called CRP 5, the fully robotized “jumbo plant”, was commissioned in mid-2022 and will increase CRP’s total annual production capacity to just over 400,000 metric tons.

CRP 5 “jumbo plant” operating since mid-2022

The newest plant, CRP 5, has the largest production capacity in Europe for manhole bases for stormwater drainage and wastewater sewers. Prefabrication will be ramped up in three stages: At the end of 2022, 180 round manhole bases are to be produced per day, with the number rising to 240 at the beginning of 2023 and further to 580 from June 2023, and, finally, to over 800 manhole bases produced in three eight-hour shifts from 2024. The new products cure in the mold; they are made from self-compacting concrete on a robotized production line that only requires two people per shift to operate – rather than 70 to 100 employees who would otherwise be needed for such a production output. On a second production line, CRP 5 simultaneously produces square and rectangular manholes in very large quantities – in this case, from conventional concrete with immediate demolding.

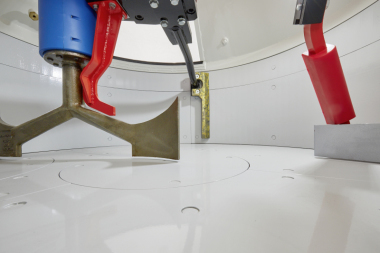

To be able to feed the two production lines with self-compacting and conventional concrete at the same time, CRP installed a new twin plant with two separate mixers. The significantly different mix designs of the two types of concrete involve widely differing water and admixture contents, which prompted CRP to opt for this technical solution allowing productivity to increase to a very high level. After contacting numerous European suppliers, CRP chose the latest generation of Teka turbine mixers, which were the only option to ensure a very high simultaneous production output of two different types of concrete while keeping batch-to-batch variations to a minimum.

As a rule, such an output level with a reject target of under 2% is heavily reliant upon the impeccable uniformity of the concrete batches produced. All new mixers were fitted with an automatic high-pressure cleaning system to complement the exceedingly productive equipment. Adopting a zero-waste approach, all concrete and rinsing water residues generated during the cleaning process are collected and fed back into the concrete mixers.

Teka leads comprehensive modernization of existing plants

Besides constructing the new plants, CRP modernized two of its existing plants completely. One of them had already been equipped with old Teka mixers from 1973 (!). Even after almost 50 years of faithful service, they were still working perfectly day after day. Yet CRP still wanted to replace them in order to minimize rejects and increase productivity here as well. The high robustness of the old mixers prompted CRP to replace them with new mixers from the same supplier, Teka. Having been in service since 2018, the new mixers produce both gray and colored concrete to a consistently high quality standard. The uncolored concrete is used for the manufacture of conventional products, while the pigmented mix containing high-quality aggregates such as quartz, basalt or granite is used for paving stones and slabs for the aesthetically pleasing design of urban spaces.

Industry partner for long-term cooperation

The considerations made by CRP’s management team since 2018 included a wide range of aspects and extremely demanding specifications, which were presented to several reputable mixer manufacturers. CRP subsequently shortlisted some of them and invited representatives of the selected companies to a joint visit to a number of production sites across Europe featuring the respective mixing equipment. Ultimately, Teka clearly emerged as the preferred supplier for the task at hand.

Not only was the world-renowned German manufacturer quick to provide assurances on all criteria relating to quality, safety, productivity, and versatility. They were also prepared to demonstrate not only new, highly automated mixers but also older installations, some of which had been commissioned several decades ago and still reliably produce large quantities of concrete every day.

“Trusting in Teka’s cutting-edge technology and the durability of the mixers convinced us because this is exactly the kind of industrial partner we were seeking for a long-term cooperation,” CRP concludes.

CONTACT

Teka Maschinenbau GmbH

In den Seewiesen

67480 Edenkoben/Germany

+49 6323 809-0