Ten consecutive years of sales growth in China

Peikko Group Corporation is a leading global supplier of Slim Floor Structures, Wind Energy Applications and Connection Technology for Precast and Cast-in-situ construction. Peikko’s innovative solutions offer a faster, safer, and more sustainable way to design and build. With subsidiaries in more than 30 countries and manufacturing bases in 12 countries, Peikko operates in Europe, APAC, Africa, the Middle East and North America. Peikko is a family-owned and managed company that employs over 2,000 professionals. Peikko was founded in 1965 and is headquartered in Lahti, Finland.

Peikko China established in 2011

Peikko China established a manufacturing base in Zhangjiagang Economic Development Zone, Jiangsu Province, in 2011, and has become the regional headquarters of Peikko in the Asia-pacific region. An annual turnover of EUR 23 million was generated in 2023 on a production area of around 15,000 m²; up to EUR 40 million is expected for 2025. Of the total workforce of around 220 employees, almost half (47%) are female, including managers.

The Zhangjiagang manufacturing base currently supplies products and solutions to multiple markets around the world, including China, Southeast Asia, Korea, Australia, the Middle East and some Europe & American markets.

Since entering China, Peikko has been committed to introducing mature European experience and technology, and carrying out localized application research and innovation according to the needs of the Chinese market, so as to better serve the local market and customer needs.

Peikko is a global leader in sustainable construction with its technologies and solutions to implement low-carbon construction in all phases of construction, including ultra-low energy buildings, green prefabricated construction, low-carbon production and circular economy of buildings.

Peikko has achieved 10 consecutive years of sales growth in The Chinese market, and has gradually established brand influence in the domestic assembly construction industry. Its connection technology and products are reliable, advanced and widely recognized by the industry.

World Class Manufacturing

Peikko China factory is a production base of global certification, Peikko Group has a comprehensive factory certification system, including ISO9001, ISO14001, EN1090, ISO 3834, ISO45001, ICC - ES, etc. The production processes are certified by the American Institute of Steel Structures (AISC), the Canadian Welding Bureau (CWB) and the Australian Code of Steel Structures (SCA).

Peikko‘s insistence on in-house manufacturing ensures product quality and flexible, fast delivery. At the same time, optimized production and logistics also ensure cost effectiveness.

Peikko always focuses on technological innovation and new product research and development, and actively participates in various industry standardization work and large international research projects, and maintains long-term cooperation with world-class research institutions and universities.

Leading in R&D and Innovation

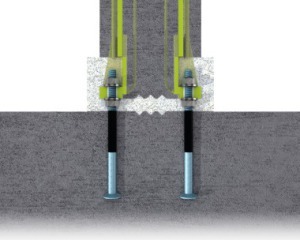

“In fact, many of the innovative solutions Peikko has introduced to the market have revolutionized the way we build, and even created a new way of building. For example: “Gangjie®” (Chinese registered name of bolted column connections)”, explaines Martin Fenčák, General Manager Peikko China.

Eith the rapid development of China´s prefabricated construction industry, Peikko invested an additional 10 million euros in 2020 to improve local R&D capacity and production efficiency, so as to better serve the needs of local customers and markets.

“In 2021, Peikko China was put into storage through the cultivation of “High-tech Enterprise” in Jiangsu Province, and passed the high enterprise certification in the same year. In the core business areas of wind power base, prefabricated and cast-in-situ connection technology, Peikko China owns more than 30 patented technologies”, added Fenčák.

Participation in Industry Standard Setting

Peikko China has carried out rigorous experiments and pilot projects on new technologies of „ultra-low energy building wallboard system“ and „fully assembled dry connection“, and participated in the formulation of relevant standards. Participated in compiling Technical Specification for Prefabricated Multilayer Concrete Structure and echnical Specification for Application of Metal Tie pieces for Precast Concrete Sandwich Insulation Outer wall Panel, which was edited by China Building Research Institute.

Participated in the compilation of Shanghai local standards: Design Regulations for Public Buildings with Integrated Concrete, for Design Regulations for Residential Buildings with Integrated Concrete and Specification for application of precast concrete sandwich insulation outer wall panel.

Participated in compiling the National Standard atlas Precast Concrete Wall Hanging Panels, which was edited by China Building Standards Design and Research Institute.

Iconic Industry Breakthrough in China

In 2018, Peikko China accomplished the very first full dry connection project together with Shanghai Chengtou Highway Investment (Group) Co. Ltd., result in 90% less labor and speed up by 7 times. In 2020, First full-dry precast connection project in high seismic area was achieved with Tianning Island Star Sand Hotel project.

In 2022, the first prefabricated ship crane project in China, the East Port Terminal Project of Maoming Bohe Port, was officially launched.

Practice Low-carbon Construction

As previously mentioned, Peikko China is committed to low-carbon construction. With green assembly connection technology, ultra-low energy consumption building, low-carbon production, circular economy and other combined strategies, layout and ecological climate expectations consistent business blueprint, to help the construction industry to achieve net zero emissions, low carbon economy and sustainable goals:

Green assembly connection technology: A more lightweight rigid connection can speed up the construction process by four times, greatly saving the consumption of building auxiliary materials and reducing the safety risks at the construction site.

Ultra-low energy building: Peikko has over 65 years of proven technology and experience in building envelope connections for ultra-low energy buildings.

Low-carbon production: Peikko‘s factories currently uses more than 60% renewable sources and is expected to reach 75% by 2025.

Circular build solutions: Peikko‘s recycled construction solution makes it possible to recycle concrete building components. The technology has passed the test of disassembly and bearing capacity and entered the pilot application stage.

Over the past ten years, Peikko has accumulated a large number of solid typical engineering project cases across the country, involving public buildings, industrial plants, policy housing, ultra-low energy consumption buildings and other subdivisions.

Further references

Peikko currently has significant portion of the prefabricated sandwich wall market in Shanghai. In the field of ultra-low-energy buildings, Shanghai Dingke Community Project, Shanghai Merchants Hongkou Siping Road Project, Jing an District Central Community Project and Jiaxing Road Sub-district Project of Shanghai Hongkou District, the first urban unit of „scientist community“ undertaken recently, are all under construction. The insulation thickness of Dalian Zhengda Qingyuan Dormitory project and Qinghai Baoheng Ultra-low energy Consumption Office Building project reached 200mm and 190mm respectively, which is the successful application of ultra-low energy consumption building technology actively explored and practiced by Peikko in cold regions.

CONTACT

Peikko Group Corporation

P.O. Box 104

Voimakatu 3

15101 Lahti/Finland

+358 20 707 511

Peikko Construction Material (China) Co., Ltd.

Nr. 1288, Fuxin Road

215600 Zhangjiagang

Province Jiangsu/P.R. China

+86 0512 58166601