The Reeperbahn in Hamburg shines in new splendor

On the Reeperbahn in Hamburg, one of the best-known streets in Germany, you are now on the safe side, even after dark, because seven suburban S-Bahn train access staircases provide a bright façade cladding of innovative light-fiber concrete. The illuminated panels were created in collaboration with the company Siut and Hering Bau.

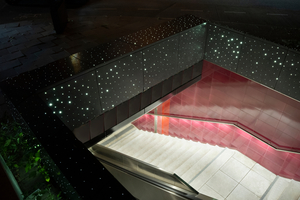

Who doesn’t know it, the Reeperbahn in Hamburg? On one of the best-known streets in Germany, you are now on the safe side, even after dark, because seven suburban S-Bahn train access staircases now feature a bright façade cladding of innovative light-fiber concrete. The illuminated panels were created in collaboration with the company Siut and Hering Bau.

What is BetoShell and what is BetoShellSiut?

BetoShell, from Hering, is a textile-reinforced, slender and light concrete façade that satisfies strictest demands on quality. The elements of the BetoShell Flex40 systems, with material thickness of 40 mm, enable a variety of design possibilities in innovative architectural concrete. The glass-fiber mats and/or carbon-reinforced concrete panels are many times lighter and therefore more resource-conserving than steel-reinforced concrete panels.

In building construction, the BetoShell textile system, in combination with licensed lighting technology from Siut Technology, offers fascinating design possibilities that are hard to equal: luminous façades.

Siut Technology is a patented production process that enables dedicated and individual integration of optical fibers in precast concrete elements. They glow out of the concrete, but can neither be felt nor are they visible when switched off. In this way, the natural properties of the concrete are retained, as well as its appearance and haptic feel. The selective integration of optical waveguides in the concrete façade elements makes the concrete material itself a source of light.

Power supply for the concrete elements takes place centrally and externally by a high-performance generator installed behind the façade cladding. Structural elements and light input are thus separated from each other. To ensure uniform light intensity as well as uniform color in the various areas of the concrete panels, several cables of equal length were installed behind the structure. As a result, the illumination is not only aesthetically attractive, but also energy-efficient. There are approx. 75 light spots per m² – and thanks to especially economical LED technology, a service life of 50,000 hours can be reliably expected. For maintenance work, the complete technical equipment, including light generators, can be removed by simply taking off the façade panels suspended from the supporting structure.

The elements are provided with four undercut anchors on the rear side and can therefore be easily mounted on a supporting structure of the system.

Reeperbahn pioneer project in Hamburg

In Hamburg, seven suburban S-Bahn stations along the Reeperbahn were modernized within the context of a program concerning the future of railroads: “Zukunft Bahn”:

as planned by the Deutsche Bahn Station & Service AG. The access staircases were given a modern look, appropriate to the location. The primary object of the new functional and design concept was to optimize orientation and customer information, to rearrange the existing facilities and to structure the entire ambience to be more welcoming and more easily navigated. Especially apart from comprehensive redesigning of the walls, floors and platforms, the façades in the stations on the access staircases of the Reeperbahn were given a more appealing design. They would have to be robust and vandal-proof. The renovation work was completed in the summer of 2022 and the project was successfully accepted.

The Reeperbahn stop was initially put into service in 1979. Today, the stop with the world-famous St. Pauli district of Hamburg can no longer be imagined without it. The stop is heavily frequented by partygoers, especially on weekends. Today, there is much more than only bars and pubs. A great variety of restaurants and attractive boutiques have become established all around the station. The highly diverse city quarter has become more fashionable – no doubt about that. Against this background, Deutsche Bahn started the renovation project in 2018. The main highlight, in the true sense of the word, are the seven access stairways with their aesthetic cladding of luminous BetoShellSiut concrete panels.

The Hering precasting plant in Burbach-Holzhausen in Germany manufactured approx. 6000 precast concrete elements with optical waveguides for the project, and installed them in Hamburg on approx. 550 m². The concrete elements were provided with an elaborately ground finish in the color charcoal.

The access staircases now provide a welcoming, bright atmosphere and enhance pedestrians’ sense of security in the evening and at night. Passers-by and passengers are presented with a light scenario that welcomes them from the surroundings and helps them find the entrance to the stations. The high quality and exciting design in combination with robust material must be the reason that so far there is noticeably little graffiti and no structural damages due to vandalism.

The result is truly impressive – an innovation with genuine highlight factor.

CONTACT

Hering Bau GmbH & Co. KG

Neuländer 1

57299 Burbach/Germany

+49 2736 27-250

info@hering-ac-com