Use of CO2-reduced cements in building practice

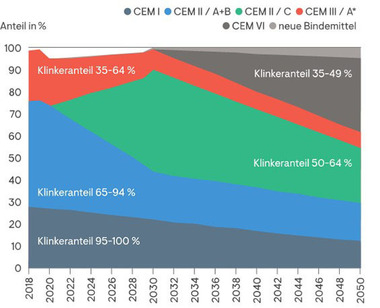

Versatility, moldability, loadbearing capacity and durability have made concrete the world’s most widely used construction material. For that reason, the environmental impact resulting from the production and utilization of concrete has come into focus. With the CO2 roadmap, the German cement industry has set ambitious aims that go far beyond what has already been achieved. Based on these measures, it may be possible by conventional reduction techniques to lower CO2 emissions by 36 % from 2019 and by 50 % against 1990. Conventional reduction measures include widespread acceptance of additional clinker-efficient cements such as CEM II/C and CEM VI. These cements contain a minimum clinker content of only 50 % and 35 %, respectively. It is planned that CEM II/C will by 2030 represent a percentage of approx. 45 % of domestic shipments. By 2050, at the latest, the content of CEM II/C and CEM VI cements is set to increase to a share of approx. 60 % of domestic shipments.

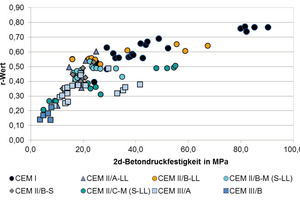

The more the content of Portland cement clinker in the cements is lowered, the more difficult it will be to prevent an increase in diversification of the performance efficiency of concrete. That means, for example, that curing of the concrete will become even more important. For concretes containing CEM II/C-M (S-LL) cements, minimum curing times are to be expected that are comparable to CEM III/A, when based on the known criteria of strength development. Further reduction of clinker content, e.g., with CEM VI cements, could lead, depending on the combination of the main constituents, to slower development of strength than is the case with cements currently being predominantly used, which would in turn lead to longer minimum curing time. In order to enable a wide future range of practical applications of new clinker-efficient cements in building practice, optimization should take place to that effect of concrete composition and construction procedures under consideration of all relevant parameters.