Use of wastes from tunnel construction as additions to concrete

The major part of mineral construction wastes, according to the German Environmental Agency, originate to around 60 % from soils and stones. The TOFFEE research project investigated the suitability of excavation material from tunnel works for use as addition to concrete. The objective of the team of several scientists headed by Prof. Dr. Christoph Budach and Prof. Dr. Björn Siebert had been to relieve landfills and to make concretes more environmentally-friendly.

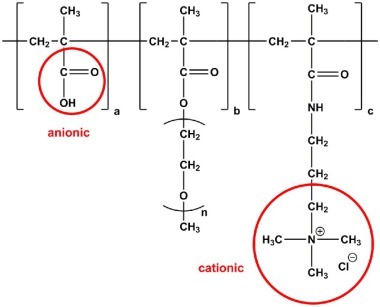

“Conventional concrete contains so-called Portland cement clinker for hardening concrete. It is made from ground clayey and calcareous rock, which is highly energy-intensive and emits enormous amounts of CO2. In order to eliminate this raw material in cement production and in this way to improve the eco-balance, we used an alternative raw material: calcinated, i.e. temperature-treated clays. These clays require significantly less energy to manufacture and are less CO2 intensive,” says Prof. Dr. Björn Siebert.

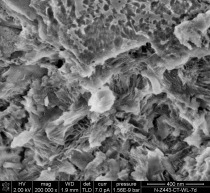

The TOFFEE project investigated three different types of clay – Paris clay, Frankfurt clay and London clay – for their material properties. The researchers of TH Cologne first described the raw form of the excavated materials to determine their suitability for calcination. This was followed by the pretreatment in a drying oven at 105 °C, as well as by sieving and subsequently grinding the material.

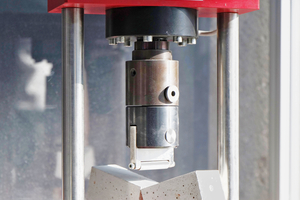

Testing the strength of the calcinated material

“To find out how efficiently the clay that had been calcinated by us would perform as binder in concrete, we made up test cubes with various cement-clay ratios. The spectrum here ranged from 100 % cement and 0 % clay up to a proportion of 60 % cement and 40 % clay,” said Prof. Dr. Christoph Budach The cubes were subsequently tested for their strength properties by Prof. Siebert in the laboratory for building materials technology by means of a hydraulic press and were subsequently classified.

The investigation of the technological properties of the building materials showed that the mixtures made by substituting 10 % of the cement with calcinated clay did not result in significant loss of strength. Even when increasing the proportion of binder up to 40 %, the calcinated clays retained their strength-increasing ability, which is referred to as a puzzolanic property. Based on the slower development of strength, compared to convention cement, the contribution to strength development of calcinated clays increases with the age of the concrete. As an additional positive effect, the research project determined, that the calcinated clays from tunnel excavation material are easier to process than the calcinated clays commonly available on the market. “Our analysis made clear that correctly treated calcinated clays develop sufficient strength to make them suitable as cement additions to concrete for construction purposes and can therefore be a CO2-saving alternative,” explained Siebert.

About the project

The TOFFEE research project – an acronym for research and activation of clay soils for resource-efficient construction materials – was supported from 2022 to 2024 by the German Federal Ministry for Education and Research (BMBF) within the scope of the FONA Research Strategy for sustainability. Affiliated partners were: TH Cologne, Brameshuber + Uebachs Ingenieure GmbH, MC-Bauchemie Müller GmbH & Co. KG, consulting engineers IMM Maidl & Maidl Beratende Ingenieure GmbH & Co. KG as well as the German Research Association for Underground Transportation – STUVA e. V. Also participating as associated partners were the German Federal Ministry of Transport and digital Infrastructure (BMDV), the Autobahn GmbH of the German Federation, VDPM Association for Insulation Systems, Plaster and Mortar e.V. and the Federal Association of the German Brick Industry e. V.

CONTACT

TH Köln

Referat Kommunikation und Marketing

Presse- und Öffentlichkeitsarbeit

Claudiusstr. 1

50678 Cologne/Germany

+49 221 8275-3731