Elematic and Eurobend sign an official co-operation agreement

An official co-operation agreement between two world-leading suppliers, Elematic and Eurobend, has been signed. The precast plant and production line supplier Elematic now offers Eurobend reinforcing equipment as part of their production lines. The cooperation helps guarantee high quality results for precast factories worldwide.

Eurobend offers the most comprehensive range of rebar processing and welding equipment covering every precast application. Their portfolio of more than 100 machine types includes fully automated and electronically controlled machines for the straightening, cutting and bending of all types of steel wire as well as mesh welding machines.

Elematic, in turn, has the industry’s widest portfolio of precast manufacturing solutions including plants, production lines, single machines, the related services and knowledge network that covers all aspects of precast concrete in buildings – manufacturing as well as the method and the design.

Similar product philosophy

The two companies have a similar product philosophy and, therefore, products that match very well together. Eurobend’s system is modular, and the degree of automation in the machinery can be increased by adding more modules to the machines.

Elematic has a very similar approach. “We have packaged our precast production line offering into three technology levels – Semi, Pro and Edge - where capacity and automation levels differ. Together with Eurobend we can offer automation levels that best meet the needs of a particular precast factory, says Lassi Järvinen, Technical Director at Elematic.

The most basic technology level ensures that getting started with precast production is easy. In time, if more capacity is required, the level of automation can be increased.

The equipment that Elematic and Eurobend offer together is a strong combination for a successful precast operation, regardless of the size and geographic location of the company.

”We are pleased to have Eurobend as our cooperation partner. They are a very innovative developer of rebar processing and welding machinery lines with a portfolio that perfectly fits for our precast production lines” says Mats Jungar, CEO of Elematic.

Top quality guaranteed

The collaboration between Elematic and Eurobend serves as a quality guarantee to precasters worldwide. They will receive the best precast production solutions combined with the most innovative and technologically advanced rebar processing and welding machinery lines.

“Elematic is one of the top brands in the precast field worldwide. Their expertise and quality product lines are the perfect match to our innovative equipment. Basically, we provide what the market has been looking for: a synergy between the two leading manufacturers in the precast and construction business sector,” says Isabel Protopapa, Managing Director of Eurobend.

“Precast is one of the most – if not the most – demanding area of the construction business. To be successful, you need to provide excellent quality and craftsmanship together with reliable, trouble-free operation. We strongly believe that the cooperation between Elematic and Eurobend will provide all that to every precast operation, regardless of size, region or continent,” says Anthony Anagnos, President of Eurobend.

Elematic and Eurobend offering

Semi: Elematic Semi technology level plant is an easy startup of precast production with a low investment. It is perfect for precast pioneers, precasters who only need a few products or builders who need production for just one particular project.

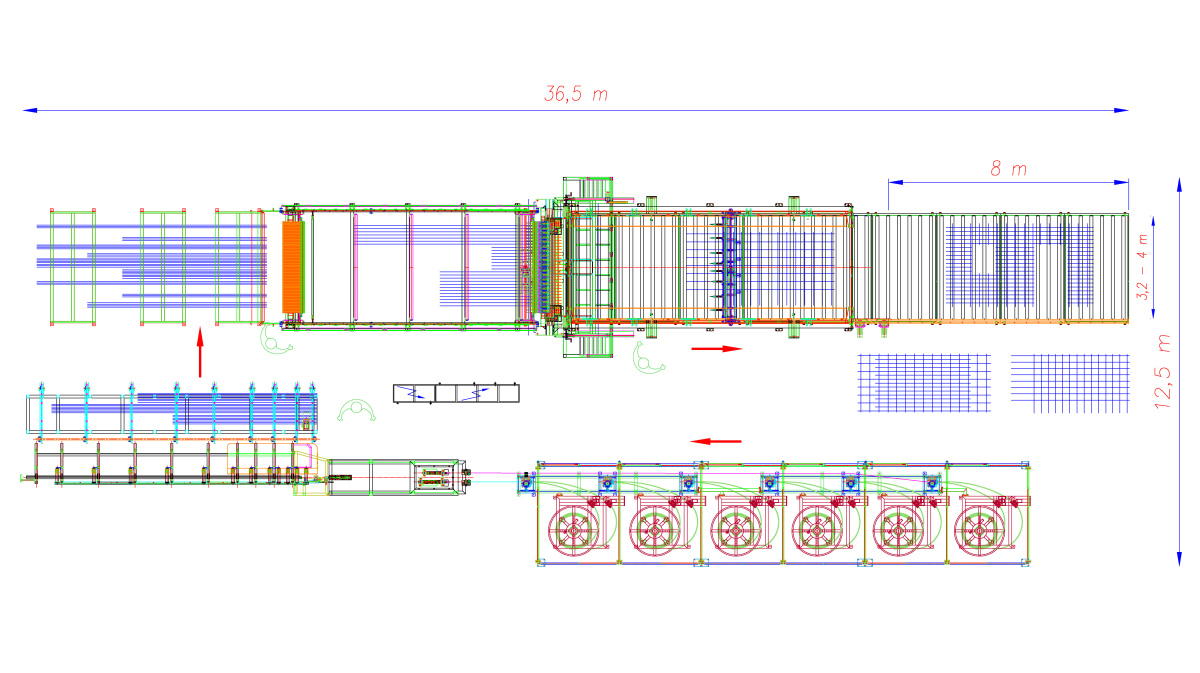

Eurobend’s machines that accompany the Semi version include an entry level straight bar fed flexible mesh welding line, together with either a single-line or flexible multi-line rotor straightening and cutting machine and an entry level rebar bending machine.

Pro: Elematic Pro production lines and machines are especially designed for producing different types of precast products with medium capacity.

For this mid-range solution, Eurobend suggests an increased capacity straight-bar-fed flexible mesh welding line, or a fully automatic, coil-fed machine version for more demanding precast operations, together with a flexible multi-line rotor straightening and cutting machine, an advanced rebar bender version and a shear line for processing larger diameters of straight bars.

Edge: Elematic Edge production lines and machines are especially designed for precasters seeking very high capacity, a wide product range, and highly automated precast production.

This high capacity production line will require both a flexible, coil-fed, or a high output, coil- fed mesh welding line, a flexible multi-line rotor straightening and cutting machine, an advanced rebar bender version, and a shear line for processing larger diameters of straight bars.

CONTACT

Elematic Oyj

Airolantie 2

37800 Akaa (Toijala)/Finland

+358 3 549511

www.elematic.com

Eurobend GmbH

Allersberger Str. 185

90461 Nürnberg/Germany

+49 911 94 98 980