15 years of quality in service

For 15 years now, the Allmendingen-based Rampf Formen GmbH has been operating a service center in the Thuringian Königshofen (Germany). The service team of Rampf is operating throughout the world. Branch manager, Reiner Schwab, is responsible for a workforce of 20 people. Concrete product molds come from all over the world to Königshofen for repair.

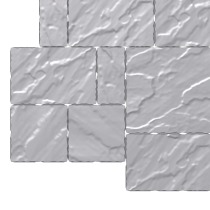

The Rampf group of companies is represented in all growth markets. Subsidiaries in the USA, Canada, Switzerland, Hungary, Poland, Mexico and China reflect exports accounting for about 80%. A large number of medium-sized family-run companies as well as internationally operating corporate groups and associations of the building materials industry belong to the customers of Rampf Formen. The Thuringian city Königshofen is not far away from the city Jena. Being expanded to a world-wide actively operating main service center for the repair of concrete product molds, the East German service center of Rampf Formen in Königshofen is as well a central address for European customers. If considering the geographical position of the service center of Rampf Formen on the map, one immediately notices that the subsidiary is located in the geographical center of Europe. And above all, in direct connection to the highway junction A9/A4, in close proximity to the logistics center of Leipzig and within the grasp of the airport Leipzig/Halle. The Thuringian factory employs 20 persons working in mold construction, as welder, steel worker, and CNC specialists. Early May 2009, the service center of Rampf Formen is going to celebrate its 15th anniversary. Branch manager, Reiner Schwab, being one of the original team, remembers very well the beginning of the factory: “It has been an ambitious road leading to the state of know-how of today’s production,” comments the mechanical engineer Schwab. On the shop floor of 1,500 m2 various concrete product molds are repaired coming from customers all over the world. Annually there are more than 1,000 concrete product molds of various kinds and manufacturers. Apart from molds for curbstones, planters or grass pavers, mainly molds for paving stones are finding the way to Königshofen,” informs branch manager Schwab. Here the slogan was created which we have remained true for 15 years: “My hand over my product.” Owing to a new three-coordinate measuring machine for measuring the stone contours and four CNC operated milling machines, step by step the service center has been cutting the cord of the parent company located in the Southern German Allmendingen during the last few years. Nowadays, the factory is in the position to examine, measure and repair signs of wear of concrete product molds in an entirely self-sufficient way. Most of the molds delivered, showing first signs of wear, have already completed between 80,000 and 100,000 cycles. “An enormous performance, considering that heavy vibration forces in the range of tons per cycle affecting in the production process of concrete products,” Schwab states. In Königshofen all repairing steps are carried out as soon as possible. After delivery of the used concrete product molds by a forwarder, the respective mold is washed at first. Afterwards it is possible for a specialist to evaluate the mold in detail. Depending on the costs and efforts and of course in agreement with the customer, the necessary repair works are carried out then at the concrete product mold. After this step of the procedure the respective stone contour is measured. Then the mold is ground and varnished until it is dispatched again to the customer through the forwarder after having been some days under repair. Various kinds of wear and tear occurring at the upper section and lower section of the mold can be the reason for a necessary expert reconditioning of the mold. When exceeding the tolerance it might become necessary to change the tamper shoes. Reconditioning of the lower section of the mold belongs also to the day-to-day work of the service team of Rampf in the Thuringian Forest. An excessive wear of the mold in the lower section – so-called “elephant’s-foot” in technical jargon – belongs to the most frequent signs of wear, which are expertly corrected in the service center. Reconditioning of a used mold is a costeffective alternative in order to extend the service life of concrete product molds. “After repairing it is absolutely possible that a mold might be applied for several more 10,000 cycles,” informs Reiner Schwab, head of the service center. The central location of the service center and the fast high-quality repair of concrete product molds by the brand product manufacturer are the strengths which the customers of the Rampf service center appreciate.

Mobile service team For different reasons a customer frequently is not in the position to dismantle the mold and to dispatch the same. Then the “Rampf service brigade” moves out to the concrete block manufacturer in order to repair straight on the ground – if necessary, even world-wide. Individual support has already been provided by the mobile work group of three in India, Canada, Russia, Ukraine and China. “However, the company clearly focuses the attention on the customers of the European neighboring countries,” Schwab says. As recently as some years ago, the branch manager had personally been on site at customers with the service vehicle of Rampf. The master mechanic, Alexander Herrmann and the mold constructor, Steffen Jahn, nowadays belong to the mobile service team of Rampf Formen GmbH. Their service vehicle, a truck with tandem trailer, is well equipped for all contingencies. On board there is among a protective gas welding machine and various grinding machines also a special tool box with a laptop, VTC vibrating table measuring instrument and mold controller. “Important spare parts for the different concrete product molds, such as duplex, rectangle and universal tamper shoes are always ready to hand,” confirms master mechanic, Alexander Herrmann. The need of any on-site support always depends on a cost-benefit analysis. “During the discussion with the customer we calculate the benefits and costs for an on-site support on the basis of experienced data gathered,” explains Reiner Schwab. If the decision is made in favor of mold repair on site, the field service engineer immediately drives to the customer. The large variety of different concrete block machines and the concrete product molds used by the customers require a profound know-how on the part of the service engineer. “Everybody in the service team of Rampf has acquired the skill to make a mold with his own hands and has reliable knowledge for attaching molds of Rampf to block making equipments of any manufacturer being applied all over the world,” ensures Reiner Schwab. Service work on site is mostly oriented on the well-proven repair work in the factory. At first, the engineer examines the concrete product mold during the production process in the block making machine. In agreement with the customer the mold is repaired. In contrast to the procedure in the service center, the technician demonstrates the repaired mold in the running production of the respective machine. In this process, the service engineer of Rampf reproduces the operation cycles of the respective block making plant with the aid of the innovative measuring system the Mold Controller of Rampf and optimizes mold filling and compaction per cycle at the same time.