Rampf Formen GmbH revolutionizes steel mold construction: Worldwide novelty presented on in-house exhibition

Rampf Formen GmbH, a leading manufacturer of brand name steel molds for the concrete block industry, presented itself a great number of customers coming from Germany as well as foreign countries at the beginning of May. The company used this in-house exhibition in order to introduce a world-wide novelty beside the well-proven product portfolio.

Rampf Formen GmbH invited business customers to the trade exhibition held at the headquarters located in the Southern German city Allmendingen. The company was pleased to welcome visitors coming from Croatia, England, Russia, Poland, Latvia, Slovenia, Turkey and the German-speaking countries. Apart from the presentation of the various products of Rampf as well as a tour of the production facilities and the stone exhibition hall, there was a quite special item on the agenda: the world premiere of a new mold!

In his entertaining welcoming speech, Managing Director Achim Rampf explained that the up-to-date manufacturing methods for the production of concrete blocks used by Rampf Formen GmbH have continuously been brought to perfection during the last few years. In the company’s own “Technology” department a team is entrusted with research and development of innovative solutions concerning the entire production process of concrete block manufacturing.

After his speech he handed over to Andreas Wörz, Product Development Manager at Rampf, who initially provided the audience an insight into conventional mold systems and the loads exerted on the respective models by these systems. In addition to this, the speech then surprised with the worldwide mold novelty called “FlexWay”. At first, this new mold sliding system was presented in an animated high-tech presentation. Afterwards, there was the possibility to visit a demonstration of this innovation held at the factory premises.

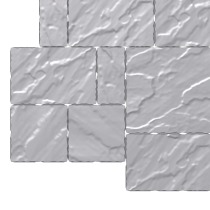

The new system optimizing the production process of block making machines directly met with great approval among the customers invited. The new patent device of Rampf called FlexWay will optimize the production process of concrete blocks all over the world – this was taken for granted among the experts soon after the on-site presentation. “With the new system we will stimulate the market and revolutionize the production process of concrete blocks, so to speak a paving block ‘made by FlexWay’,” remarked Product Development Manager Andreas Wörz.

The most important features of FlexWay are an extensively minimized wear and tear of the concrete block mold and the variable application of the new mold sliding system together with all paving block molds of Rampf. All these features enhance the quality of the finished concrete block considerably. In addition, the cycle performance will be increased and the reject rate decreased. In this way, costs and expenses will be reduced mold by mold.

The company expects further interesting marketing opportunities also for the future, owing to the continuous development of the products. On the occasion of the in-house exhibition the company showcased a cross-section of the well-known Rampf products in an exhibition tent, such as Quick Box, Mebaform, Oscillator, Sliding-Panel Mold, Vibration Table Controller or even a mold equipped with heating as well as a Mold Controller. In the conference room Service Manager, Otmar Sontheimer, took the opportunity to explain industrial professionals in a speech the great variety of services offered by Rampf Formen GmbH.

Concrete block manufacturers from all over the world are among the business partners of the manufacturer of brand name steel molds for the concrete block industry. The Rampf group of companies is represented in the most important growth markets. Among others, internationally operating corporate groups, associations and medium-sized family-run companies of the building materials industry belong to the customers. Subsidiaries in the USA, Canada, Switzerland, Hungary, Poland, Mexico and China reflect exports accounting for 80%.

Address/Anschrift

Rampf Formen GmbH

Altheimerstr. 1

89604 Allmendingen/Germany

Tel.: +49 7391 505 0

Fax: +49 7391 505 142

info@rampf.de

www.rampf.com