Peri Pave – tested and proven in practical application

In the meantime, the production pallet Peri Pave has convinced a lot of manufacturers of concrete products. This, in particular, points out the fact that the manufacturers of concrete products pick out them again when equipping additional plants.

MBI Beton in the Netherlands has as well been manufacturing on Peri Pave pallets for several years. Positive experiences gained over many years of practical experience and a quite elaborate trial have been the decisive factors for furnishing several plants in the past years with the production pallets from Weißenhorn (Germany).

The first of the two circulating production facilities at the headquarters of MBI in Veghel was equipped with the production pallets in 2005. Plants at two further locations followed in 2006 and since last year the pallets have also been used for the second circulation in Veghel. “There have been various reasons why the decision was finally made in favor of Peri,” says Peter Leijen, purchasing manager at MBI.

Tried-and-tested quality

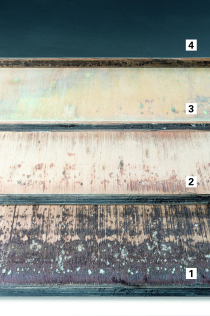

MBI is convinced of the high quality of the materials used and in particular of the core made of birch plywood. “We have been present during the manufacturing process of the production pallets and were therefore able to convince ourselves of the quality right on site,” explains Leijen. The experience made in practice at MBI confirms the impression: the condition of the pallets is to be evaluated

extremely positive, even after several years of application in air-conditioned chambers at warm humid climates (approx. 95% humidity and a temperature of 30°C) as well as for the production of washed-out concrete products. Even longer exposure times of the pallets in the hardening chamber are possible without any problems. The high stability of the pallet was an essential aspect for MBI. “Despite the high loads the pallets show a minimum deflection.” Furthermore, the closed surface of the pallet, which ensures a good quality especially in case of large-scale concrete slabs (“Gigategels”) with a surface of up to 1.20 m2, was a significant factor for the decision.

Durability proven in factory tests

Before taking the final decision in favor of an additional capital expenditure, MBI carried out a very elaborate trial in the own factory with various production pallets available in the market. Within a testing phase of just a few days a service life of eight years was simulated. The evaluation that followed not just confirmdid the stability of the core, but above all the newly developed coating turned out to be resistant to abrasion and long-lasting.

“Down to the present day, the current construction of the Peri Pave production pallet entirely comes up with our expectations and we are convinced that this will be all the same in future too,” comments Peter Leijen. “The price-performance ratio is overall satisfying and in particular technological further development of the product is very interesting for MBI.”

Peri as partner

“We had many good discussions with Peri, which at least contributed to our decision,” says Peter Leijen. He knows his contact persons in Weißenhorn and feels to be in good hands there. It goes without saying that in case of such an investment for MBI customer support was quite decisive, and as well in this regard the company in the Netherlands was satisfied in the same way. “We consider” Peri as partner, since also the after-sales service is good in every respect.” That there is such a big company behind the people known to him gives an addition sense of security to MBI, adds the purchasing manager. With a world-wide workforce of about 5,400 people and an annual turnover of about 1.2 billion (2008) Peri is an international market leader as regards formwork, scaffolding and engineering. The company stands for quality, reliability and innovation.

Address/Anschrift

Peri GmbH

Schalung Gerüst Engineering

Rudolf-Diesel-Straße 19

89264 Weißenhorn/Germany

Tel.: +49 7309 950-0

Fax: +49 7309 951-0

florian.brandl@peri.de

www.peri.de