KANN and PERI Pave – strong partners for mutual success

KANN Baustoffwerke GmbH selects production pallets for the manufacture of concrete blocks after thorough material testing and according to the maxim: Every plant gets the optimum individual solution. Since 2007, PERI Pave has already scored several times when the Bendorf-based company made a decision for the optimum board. In the meantime, the tried and tested multiplex pallets provided with a plastic coating that is highly resistant to abrasion is the first choice for a total of 13 plants at nine locations of KANN. Below-mentioned are some of the experiences made at the Mittenwalde facility in the Brandenburg region of Germany.

One of German‘s leading manufacturers is currently operating his most efficient concrete block factory there, generating an annual output of just over 250,000 tons. The production runs all year round in a three-shift operation; the entire manufacturing process on two Masa plants is designed for a smooth workflow of the process chain, based on the high throughput. Changing the production pallets is regarded, on the one hand, as a measure to increase productivity and, on the other hand, to guarantee the high quality of the concrete products.

Core strengths

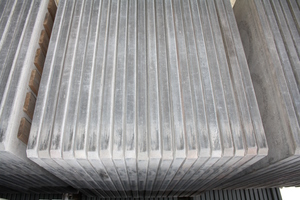

The Mittenwalde-based company has been working with PERI Pave production pallets since 2013 and 2014; they have passed more than 750 cycles each until today. The pallet size is 1400 x 1050 x 48 mm, at which the relatively low own weight of 52 kg is confronted with partially high load applications. PERI has dimensioned the pallet thickness individually according to the maximum load case.

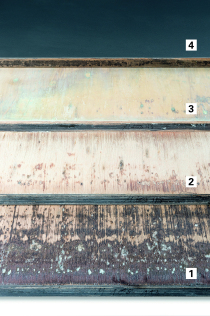

The factory had used softwood and hardwood boards before the replacement. After thorough tests and several years of practical experience, factory manager, Mirko Adam, is now in the position to draw a comparison between those and other pallet types: „In technical terms, the PERI Pave convinces with a very consistent transfer of vibration due to the homogeneousness of the multiplex pallet,“ Adam states.

Actually, the production pallets are characterized by their particularly high and uniform stiffness. This is due to the design of the 1.4mm-thick birch plywood veneers which are cross-wise bonded to each other. This results in a maximum dimensional stability, ensuring an effective and uniform transfer of the vibration forces during compaction.

Adam concludes the difference in practical terms from the production of concrete blocks under identical manufacturing conditions. The outcome: The block thickness was always clearly smaller on PERI Pave in comparison to softwood pallets, and the concrete structure was denser accordingly. As a consequence, the factory could reduce the vibration forces, shorten cycle times and save raw materials. In addition, the reduction of vibration energy has a positive effect on the service life of the entire plant equipment and the energy costs.

Besides the good compaction results, the factory manager refers to the loading capacity of the PERI Pave. Adam uses the heavyweights in the production as benchmark. In this case, nine curb units with an edge length of 1,000 mm each sum up to about 630 kg of load applied to each production pallet. The maximum deflection after long-term loading shown at the PERI Pave is so small that Adam can conclude this topic in short with „No problem!“.

The decisive factor for the remarkable load-bearing behavior for both longitudinal and transverse transport again is the multiplex core that is extremely stable and resistant to bending. High loading capacity, moreover, means small pallet thickness and savings in weight for the benefit of the entire production process.

Protecting consistent quality in the long term

The production pallet is provided with a specially designed, highly abrasion-resistant polypropylene coating. The rigid but impact resistant plastic has especially been developed by the specialists at PERI for heavy-duty operation in the concrete block factory, with also taking the resistance to chemical substances in release agents and block impregnation into account. The joint-free coating above all provides for a perfect reverse side of the block, without the need of withdrawal plates.

The edges of the pallets are generally open to vapor diffusion, but they are treated with acrylic lacquer to protect them against large quantities of water, as occurring in case of washed concrete products. This ensures that the pallet structure does not absorb water in an uncontrolled manner and does not swell, but moisture can be continuously diffused out.

Moreover, the individual layers of the multiplex pallet are bonded in a water- and boil-proof manner, which is guaranteed by PERI throughout the service life. The pallets are manufactured by one of the worldwide leading specialists in plywood products, the Finish company UPM. Birch wood with a high density from PEFC or FSC certified, sustainable forest management is exclusively used for the plywood core.

Conclusion

In summary, PERI Pave is convincing with an optimum interaction of the transfer of vibration forces, stiffness, load-bearing capacity, flatness and the surface coating. All this enables the KANN company to achieve good results. Purchasing manager, Carsten Märker, states another reason: „Apart from the technical characteristics, the cost-effectiveness also counts ultimately. In this regard, we made very good experience with PERI Pave.“

Outlook on innovation

The product strengths in terms of technology and efficiency are the basis for the long-term cooperation with companies like KANN. PERI product manager, Kathrin Wunder: „Satisfied customers are the crucial factor for us. We are aiming at long-term co-operations, where we develop solutions hand in hand for the mutual success. We offer our customers products and services based on high practical relevance, since they have been developed together with the user. Because the production pallet not only is a means of transport, but rather a decisive factor in production for strengthening the success of our customers,“ Wunder states.

PERI announces to present the latest development at Bauma 2019 held next April in Munich: the PERI Pave – Generation 2.0. A new feature is the modified plastic coating with integrated release effect against adhesion of concrete and acrylates, with otherwise unchanged high technical characteristics. PERI will present the innovation from April 08 to 14 in hall FN.719.