Trapezoidal sheet fastenings

Till autumn 2009, Ikea is expanding its world’s largest distribution center up to almost 800,000 pallet places. The general contractor, Klebl GmbH of Upper Palatinate/Germany, among others, is responsible for roof and façade. In this regard, the company relies on a quick and cost-effective trapezoidal sheet fastening system.

Since 2001, Ikea has kept on constructing its already now largest distribution center in the world, which is located at the water-way “Dortmund-Ems-Kanal”. On a former mining ground in Dortmund-Ellinghausen almost 500,000 pallet spaces have been built on a surface area of about 270,000 m2 in fully automated high rack storages. Till the autumn of this year, additional 290,000 pallet spaces shall be built in a further stage of construction on a surface area of 129,000 m2. “We are going to invest 120 million euros here at the location in Dortmund for the completion of a 730 x 180 m hall. With this expenditure we are considerably expanding the distribution capacity for our European furniture stores with small-volume product lines and special items,” explains Harald Wöhlbier, Site Manager with Ikea.

General contractor for this project is Klebl GmbH located in Neumarkt (Germany). Within one year, the company of the Upper Palatinate is going to create a building structure totaling to 2,164,700 m3 closed-in space made of precast concrete components. For this purpose, Klebl is manufacturing more than 3,700 precast concrete components in its precast concrete plants in Gröbzig, Gönnern and Neumarkt. The dimensions of the precast components are quite significant. Just the columns of the hall have a length of 32 m and a weight of 70 t.

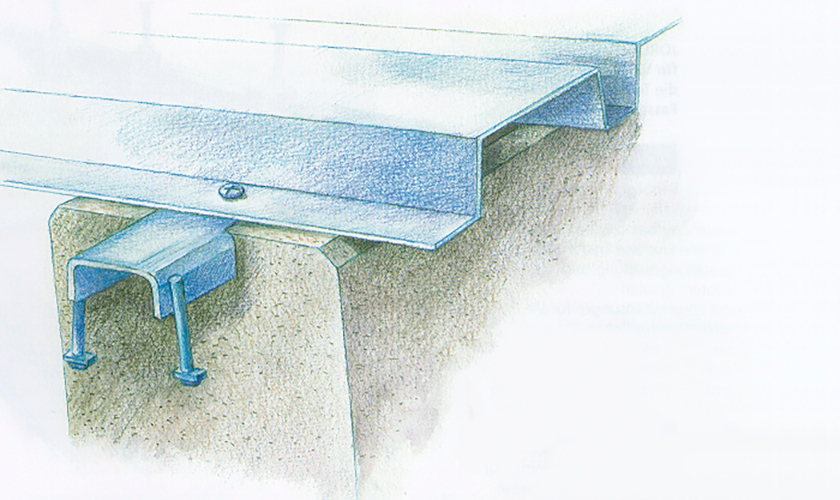

The roof and the façade of the hall will be constructed of thermally insulated trapezoidal sheet. For the roof trapezoidal sheet of ThyssenKrupp type T 150.1 will be used and for the façade the wall trapezoidal sheet 35/207. For quick and cost-effective fastening of the trapezoidal sheets both the roof and the façade elements, Klebl decided to use the Jordahl® trapezoidal fastening system of Deutsche Kahneisen Gesellschaft (DKG). The responsible project manager at Klebl GmbH, Michael Staudinger, explains: “For mounting the trapezoidal sheet we need a large number of specialized staff and equipment. In favor of a smooth construction progress it is necessary to use a quick but also cost-efficient mounting system. In consideration of these criteria the trapezoidal sheet fastening rail system is, of course, a well-proven choice.”

The anchors of conventional fastening channel systems are often difficult to insert in prefabricated reinforcement cages. The chosen fastening channels of type JTB-60/24/3-AR can be incorporated more easily into any existing concrete reinforcement, due to the slender anchor shape. The anchor channels of DKG are approved by building authorities under number Z-21.4-161. As channel material steel according to DIN EN 10025, hot-dip galvanized with a zinc coating of 50 micrometers was chosen in Dortmund. The 3 m long channels supplied by the Berlin-based company with anchor spacings of 450 and/or 150 mm are centrally divisible, allow cutting in half and are therefore cost-saving as well. The applied fastening channels of Jordahl are suitable for supporting loads in all directions. Depending on the anchor spacing the channels bear point loads of 5.0 kN (anchor spacing of 150 mm) and 3.3 kN (anchor spacing of 450 mm). When shortening the channels, a maximum spacing of 75 mm to the next anchor has to be observed.

Already in the precast concrete plant of Klebl, the channels with inserted foam filling are set in concrete to be flush with the surface and in alignment. The end joints between the fastening channels add up to 20 mm. Finally, the trapezoidal sheets are mounted onto the fastening channel by means of galvanized self-tapping screws with sealing ring. “However, what is crucial for our decision for this fastening channel system is, of course, the quality of the system, the processability of the same and certainly the price,” Michael Staudinger states. Till the completion of the hall, which will have a height of 33 m in the area of the high rack storage, a total of 151,000 m2 of trapezoidal sheet for the roof and the façade will be mounted.

By the way, giving the go-ahead for the location in Dortmund, the world’s largest home furniture brand not only took a decision in favor of German construction companies but also provided new jobs which are badly needed in the region. The number of people employed at the distribution center of Ikea and at the respective service providers amounting already to 1,300 will be increased by additional 250 colleagues in 2009.

Address/Anschrift

Deutsche Kahneisen

Gesellschaft mbH

Josefine Niemand

Nobelstraße 51

12057 Berlin/Germany

Tel.: +49 30 68283482

Fax: +49 30 68283497

j.niemand@jordahl.de

www.jordahl.de