Fastening anchor channels with installation cones

High quality demands are placed on precast elements made of reinforced concrete. They pose a particularly high challenge with regard to the geometry. This also applies to the built-in components such as for example anchor channels. The position must be precisely coordinated with the planned reinforcement, which is often laid very tightly. Planning a reinforcement of exactly ¼ mm is currently no longer rare. Therefore perfect positional securing of the components is of utmost importance so that the components do not shift when the concrete is being poured. The positional securing must on the one hand be firmly attached to the formwork. On the other hand it must ensure that no damage appears on the formwork and the precast element, when removing the precast element from the formwork.

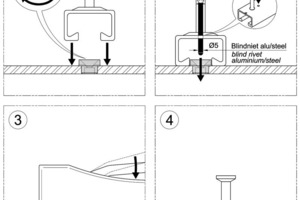

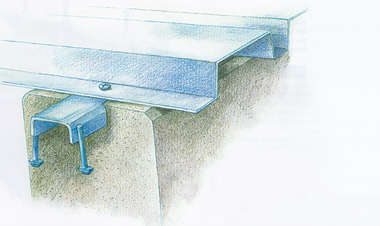

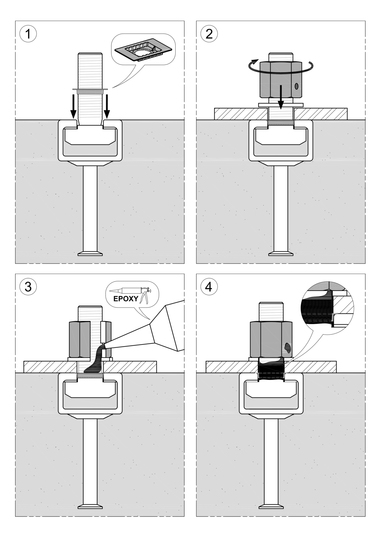

In order to fasten Jordahl anchor channels to steel formwork, the precast element factory of the company group Max Bögl in Sengenthal successfully uses the Jordahl installation cone. This accessory made of steel has a threaded pin on the one end and is funnel-shaped on the other end. For the installation, a threaded hole is made in the steel formwork at the intended fastening point into which the installation cone is screwed. The installation cones are placed along the axis of the projected anchor channel at a distance of about 500 mm.

Major project with about 500 elements

Next, the anchor channel is positioned and fastened to the installation cones with blind rivets through the existing nail holes. The fitness for purpose of the Jordahl installation cones was proven at the end of 2016 in a major project. For this about 500 precast elements with curved Jordahl anchor channels were produced. The uniqueness here: The anchors featured irregular distances so that they could be perfectly matched to the reinforcement. Owing to the installation cones, the anchor channels were yet perfectly positioned even though the anchor channels presented a special challenge due to their curved design. Stefan Bachschmid, the project leader for the tubbing production at Max Bögl, is very happy with the fastening solution and praises the constructive and smooth cooperation with Jordahl.