Five automated processes for more efficiency in precast project delivery

20.05.2021

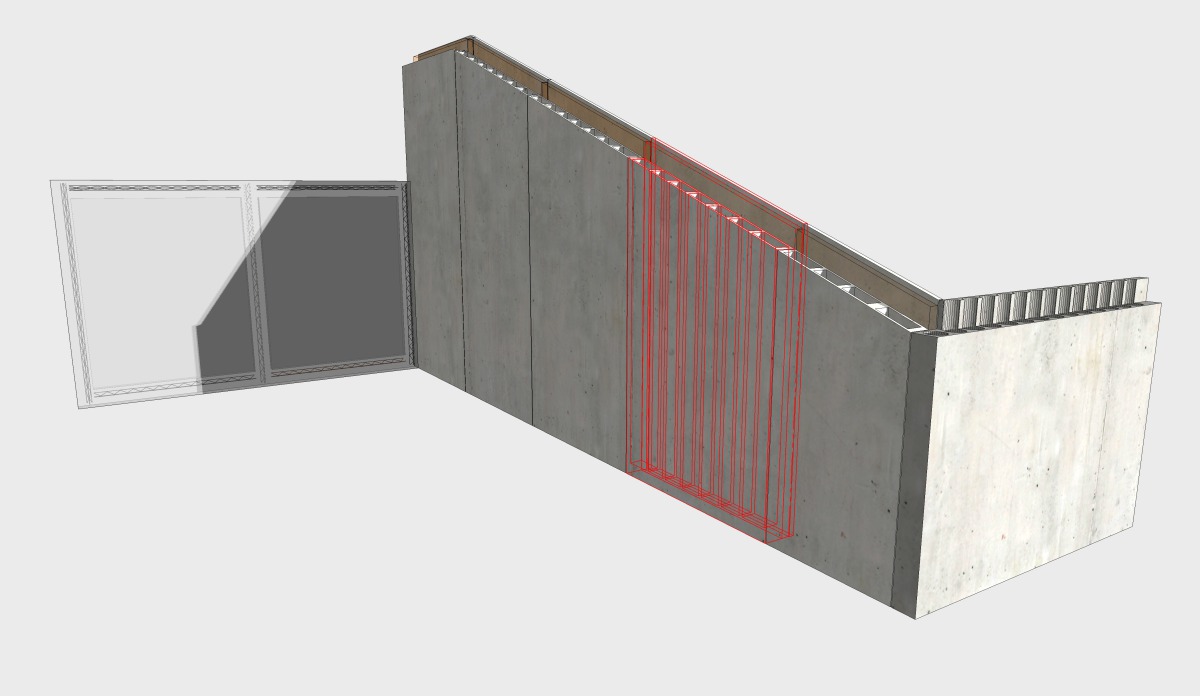

The more complex and larger construction projects are, the more participants work together on the project (Figure: Precast Software Engineering)

The more complex and larger construction projects are, the more participants work together on the project (Figure: Precast Software Engineering)

Increasing time pressure, changes to the construction project at short notice, cost efficiency, ever more complex projects, higher demands on architecture and an increasing number of participants characterize the construction projects of our time. Furthermore, everybody is talking about buzzwords such as BIM, digitalization or automation. Yet the challenge is to really implement these key words in a concrete and profitable way in the daily work of precast teams. So which screws within the design process can now be turned to achieve the necessary increases in efficiency?

Data import made easy

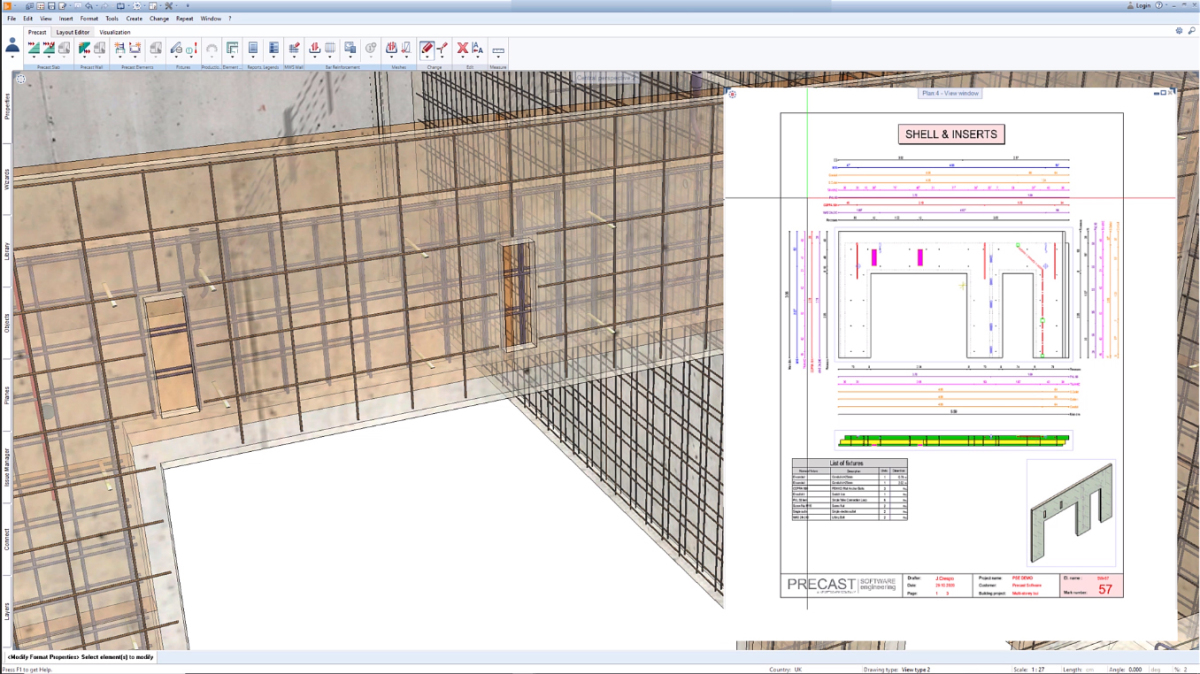

Such large-scale projects often involve the same elements (Figure: Precast Software Engineering)

Such large-scale projects often involve the same elements (Figure: Precast Software Engineering)

Multiple tracing and matching of data often leads to errors and costs valuable time. Meanwhile, innovative CAD programs have intelligent assistants that import architectural plans, structural design and technical building technology without any loss of quality. The MEP assistant in Planbar from Allplan, for example, takes care of the comparison of the imported fixtures with catalogs. It quickly and easily converts non-standard IFC objects into customer-specific fixtures. As a result, users with just one major project can quickly save several working days annually.

Increase productivity in design

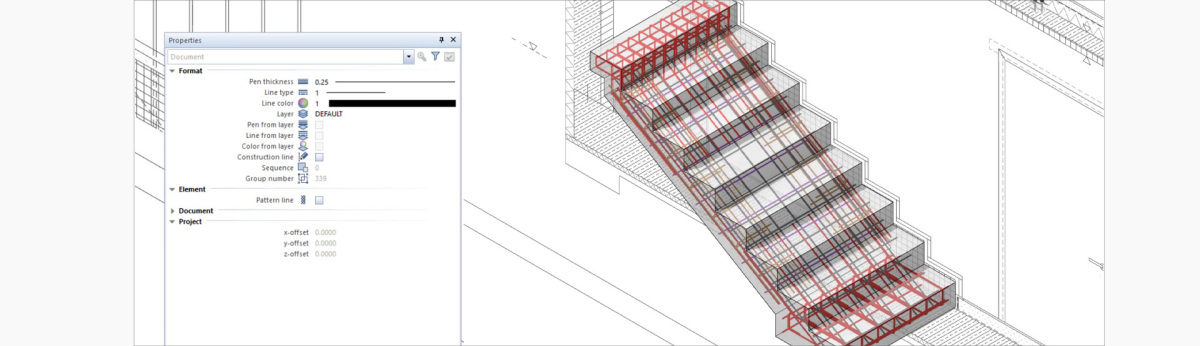

Plans impress with their clarity, models with their vividness. The combination of 2D with 3D represents a quantum leap in efficiency: with its unique Elementplan technology, Planbar enables model- and plan-oriented work. This is because the plan is not a mere 2D derivative of the model, but a view of the model itself. This means that the model and the plan are always 100% consistent. Planbar automatically creates all shop drawings including reinforcement, fixtures and dimensions - not according to a standard scheme but with the help of intelligent templates. Changes in the plan are automatically adopted in the model and vice versa - a major productivity gain.

The creation of structural precast parts is particularly efficient thanks to parameterized, interactive input, for example with the help of customization using Python programing. A few inputs are all Planbar needs to automatically calculate and design columns or stairs. This optimizes lead times and workload in the design team.

Facilitate collaboration on large projects

The more complex and larger construction projects are, the more participants work together on the project. Suitable software enables the design team to work simultaneously on large construction projects. Such large-scale projects often involve the same elements. In conjunction with Planbar, BIM Booster ensures that all identical elements, such as fixtures or reinforcement, are automatically synchronized in the background. Because the software takes over repetitive work, the design team gains valuable time. The BIM Booster also ensures a reduction in the amount of data without any loss of quality.

Efficient work preparation and quality-assured data

Successful precast design requires reliable work preparation. A customer-specific, rule-based quality assurance is essential here, which is used in particular to check secondary conditions relevant to production, transport and invoicing. Tim|work for manufacturers relieves the workload of numerous routine tasks and supports work preparation in production planning, 3D stacking and assembly, billing and quality-assured data creation. As a result, this work preparation tool ensures greater efficiency, precision and accuracy.

Single source of truth

However, it is not only the quality of the data that is crucial, but also that the right data is in the right place. Tim|flow software takes on the role of a data hub and ensures automated information flows between ERP, CAD and MES. This eliminates numerous manual work steps and increases the quality of the data. Openness to other systems and the processing of different data formats in the sense of openBIM enable a smooth data flow within the project.

Efficiency in the design process is thus the sum of all small and large screws, which in their entirety ensure the decisive productivity advantage. Software takes on the role of a game changer and helps companies to use automation and digitization to their advantage. Christian Schernthaner, Head of Sales at Allplan Precast puts it in a nutshell: "Use the automation potential of the best design and planning software - you will be impressed by the productivity gains achieved."

CONTACT

ALLPLAN Software Engineering GmbH

Urstein Süd 19/1/6

5412 Puch b. Hallein/Austria

+43 6245210010