Milestone in the field of digital construction - Peri and DataB establish joint venture

22.01.2025

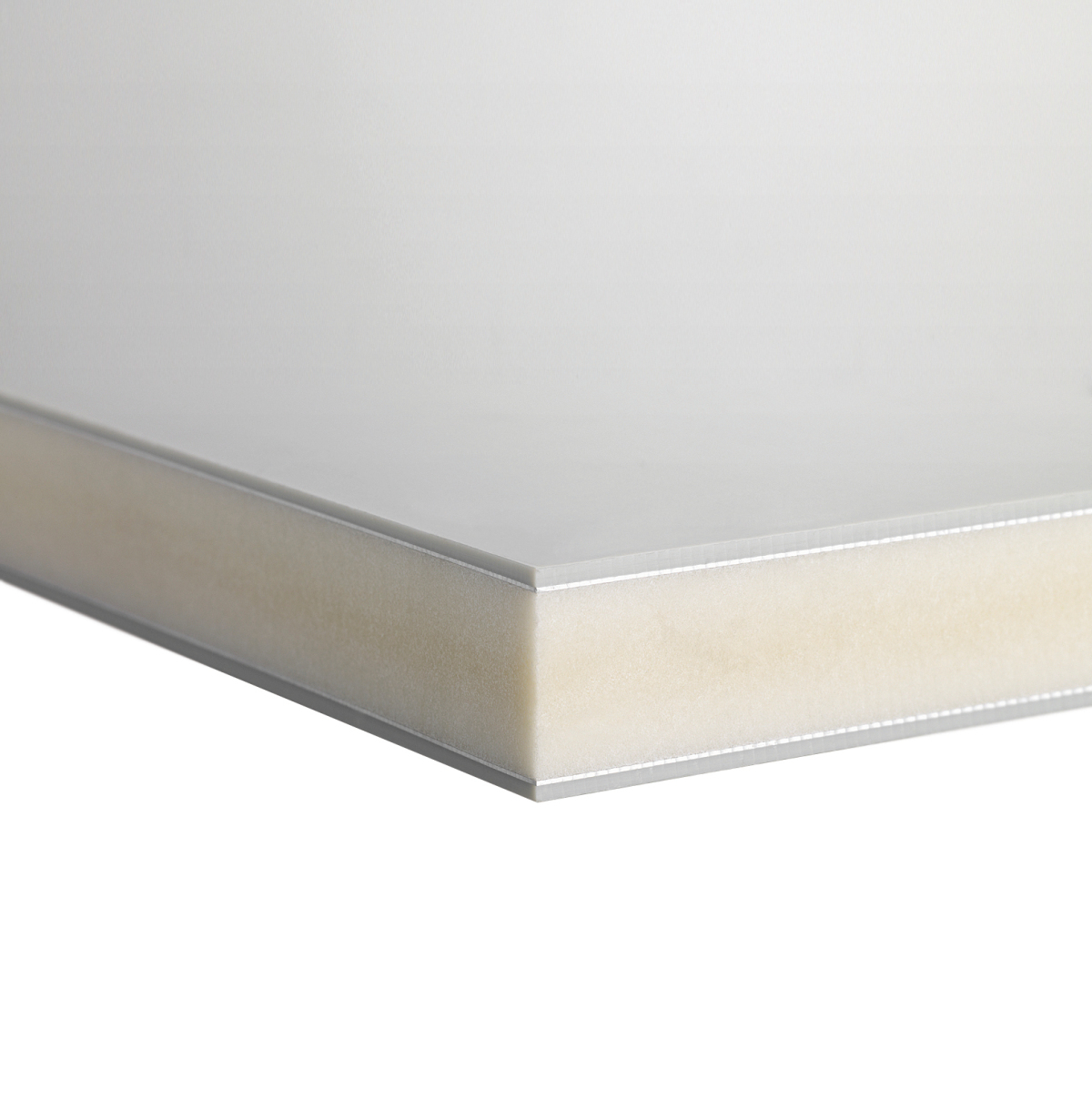

Figure: Peri SE

Peri SE (Weißenhorn, Germany) and DataB GmbH (Biedermannsdorf, Austria) founded the joint venture DataForm.Work GmbH on 8 January 2025.

Both partners each hold a 50 per cent stake in the joint venture, which is based in Biedermannsdorf (Austria). René Østergård will assume the Managing Director role of DataForm.Work GmbH. The Danish engineer brings extensive experience with almost 10 years at Peri.

With the founding of DataForm.Work, two innovation-orientated companies are combining their strengths to jointly drive digitalisation in the market segment for custom formwork solutions with a revolutionary technology and a newly created business model in this very demanding area of construction.

Comprehensive market knowledge

As one of the world's leading companies in the formwork and scaffolding sector, Peri contributes comprehensive market knowledge, sales experience and engineering expertise in all areas of application for concrete formwork. With the development of a software technology for the design and automated production of custom formwork solutions, the partner DataB has developed an innovative new technology that is now ready for the market.

Custom formwork for bridges

Custom formwork is required in particular for infrastructure projects (especially bridges) but also for aesthetically sophisticated cultural buildings (such as museums). Wherever the building material concrete has to be moulded into shapes that cannot be achieved with ‘standard’ formwork solutions due to architectural-aesthetic or structural requirements, DataForm.Work offers solutions that accelerate the planning, calculation and, last but not least, the actual production of custom formwork solutions making it significantly more efficient and cost effective.

The software developed by DataB automatically generates the substructure of the custom formwork in a reduced amount of time. This design is transferred directly to a CNC machine and produced with unprecedented dimensional accuracy. DataForm.Work uses a unique plug-in system for intuitive assembly.

DataForm.Work offers its customers two solutions:

”Complete service” by DataForm.Work: The planning information is generated using AI software, before being transferred directly to the CNC machines in the joint venture's production hall. There, the panels are milled and the custom formwork is assembled. The finished elements are then delivered to the customer.

“Formwork as a Service” business model: DataForm.Work is responsible for generating the substructure design for the custom formwork. This data is then transferred to the customer’s CNC machine, that is provided by Dataform.Work. The milling and assembly of the final custom formwork elements is carried out in-house by the customer. As the software generates a highly detailed assembly guide, this last step can be carried out regardless of the workers’ experience, even for the most complex custom formwork projects.

‘For our customers and their projects, digital construction with DataForm.Work solutions means significantly improved planning reliability, efficiency, flexibility and speed,’ says René Østergård. ‘We are convinced that our offering represents a technological leap forward in the field of custom formwork construction.’

CONTACT:

Peri SE

Schalung Gerüst Engineering

89259 Weißenhorn/Germany

+49 7309 9500