Hörmann Refrigeration: Cool concrete for Cairo Metro civil works

03.04.2018Egyptian-French joint Venture (Bouygues, Vinci, Arabco and Orascom) to use Hörmann technology for concrete temperature control: the consortium took responsibility for extending Line 3 of the Cairo mass transit system. The Line shall cross under the two branches of the River Nile with a tunnel and further extend with a bridge in the city. The latter mass concrete constructions require special strength. Therefore, the constructors must accurately control the temperature of the concrete, which they produce in extreme weather conditions (ambient temperature at 45 °C, cement 65 °C). For this purpose, the constructors missioned the specialized German refrigeration company to design, size and supply their new cooling system. Hörmann GmbH, will supply the cooling system, who developed a unique know-how in this field for thirty years.

Fighting the heat of hydration with ice

The "heat of hydration" released during the concrete mixing, can exceed twenty degrees, which adds to the already hot temperature of the aggregates (In Cairo, a temperature between 35 °C and 65 °C is being considered for aggregates and cement). The warm concrete mass shrinks while cooling at night and minute cracks occur, which would greatly impair the strength of the construction. Therefore, it becomes necessary to Control the magnitude of this thermal fluctuation, by adding cold water (3 °C) and ice in the batching phase. The large latent heat of fusion of the sub-cooled ice (-5 °C) on the one hand and the large heat-exchange area of its thin particles on the other hand, make it possible to manage an effective control of the temperature of the mix, in a quick and accurate way, thus achieving a high grade of concrete.

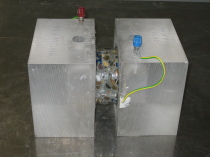

Containerized water chiller and ice production plant

Dosing these "cold materials" into the mixer, will enable to poor the concrete in Cairo at 22 °C. The Hörmann plant is tropicalized and operates up to a 50 °C ambient temperature. The refrigeration circuit and components are contained inside a 40 ‘High-Cube ISO container, transportable by truck or boat. The installation does not require any additional building. It is easy to start after connections (electrical, hydraulic) and refrigerant charge. It can be transported and relocated to another site at the end of the project. Containerized cold water and ice storages will enable to sustain ice production at night while construction work is off. Ice delivery to the mixer is fully automatic.

Thermal performance and environmental protection

The plant is charged with Ammonia, a high performance refrigerant fluid with far better thermodynamic properties than Freon. The resulting performance gains enable an estimated 15 % power saving. What's more, the Global Warming Potential (GWP) of this fluid is null, as well as its Ozone Depletion Potential (ODP).

CONTACT

Hörmann GmbH Refrigeration

Weiherstr. 8

89251 Illertissen/Germany

+49 7303 5423

i