Solid Unit: Circular economy needs short distances and regional solutions

14.03.2025

Figure: Werner Rothenbacher, Schwenk

"Our goal must be to reduce the consumption of resources and the volume of waste in the construction industry and to consistently promote circularity," emphasises Thomas Zawalski, Managing Director of Solid Unit Germany. The need for a different approach to materials is also reflected in the figures: According to the latest monitoring report from the Circular Economy Construction Initiative, there is an annual demand for around 564 million tonnes of aggregates in Germany.

Regionality as a decisive factor

However, it is important to know that the availability of RC material is currently limited and cannot be increased at will. The supply depends heavily on the amount of deconstruction material produced. The recycled construction materials produced in 2022 could only cover around 13 per cent of the demand for aggregates. In turn, around half of this is already being reused in road construction - with an almost closed material cycle. The regional availability of substitute building materials should therefore always be a priority. Dismantling on site, recycling and reusing the materials directly on the construction site - an ideal cycle in terms of sustainable resource utilisation. After all, emissions can also be reduced with recycled aggregates if their use does not result in additional transport routes.

Planning and building in cycles

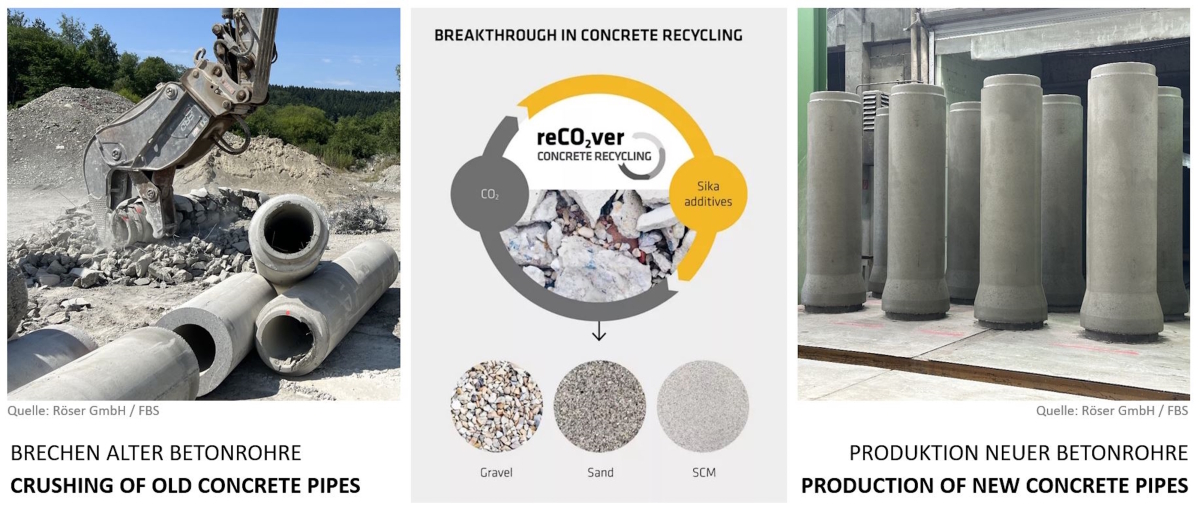

R-concrete is already being used in numerous construction projects, such as the recent modernisation of the MHPArena (formerly the Mercedes-Benz Arena) in Stuttgart or the construction of the new town hall in Korbach, Hesse. In a recycled house pilot project in Heek, North Rhine-Westphalia, the entire aggregate was even replaced with mixed demolition material.

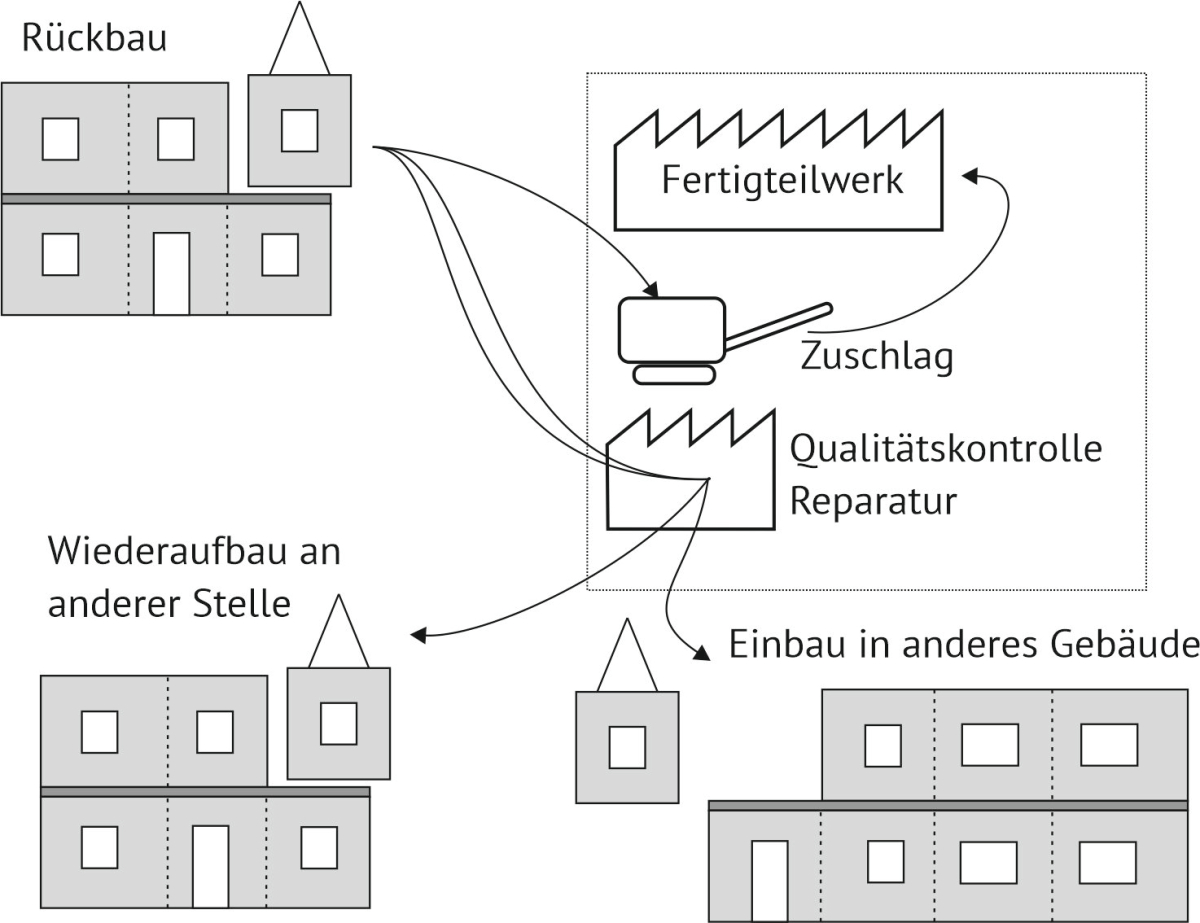

There are also promising innovations in masonry construction, such as the unfired cold brick made from recycled material or the KS circular brick. In addition, the reuse of materials from other cycles - such as iron and steel slag from steel production - helps to conserve resources. Responsible handling of building materials, excavated material and demolition material ideally begins as early as the planning phase. Corresponding digital trading platforms are already on the market.

"A functioning circular economy is fundamental to sustainable resource management. The use of secondary building materials should be increased, taking into account regional availability and existing material cycles, and their utilisation should be considered in planning from the outset. Regionality is a decisive factor for the environmental balance of the circular economy. Emissions can be further reduced by using CO2-reduced cement. This applies to all concretes, not just R-concrete," concludes Thomas Zawalski.

Further details on the practical examples mentioned and other innovations can be found on the Solid Unit website at www.solid.unit.de.

Event tip:

On Wednesday, 19 March 2025, Solid Unit invites you to the web seminar ‘Circular construction - planning tools and practical examples’ from 12:30 to 16:00. The speakers are Dr Andre Baumann, State Secretary in the Ministry of the Environment, Climate and Energy of the State of Baden-Württemberg, Markus Tresser, Innovation Centre for Circular Construction at the State Institute for the Environment of Baden-Württemberg, Christian Landes, N1 Circular GmbH, Markus Meier, construction company Martin Meier AG and Dipl. Ing. Architect Benno Tillmann, Bau- und Liegenschaftsbetrieb NRW. Registrations are now possible at www.solid-unit.de.

CONTACT

Solid Unit

Wiebke Zuschlag

+49 621 423 01 42