The world's first series-produced concrete cap slab

02.09.2024

Figure: concap

Figure: concap

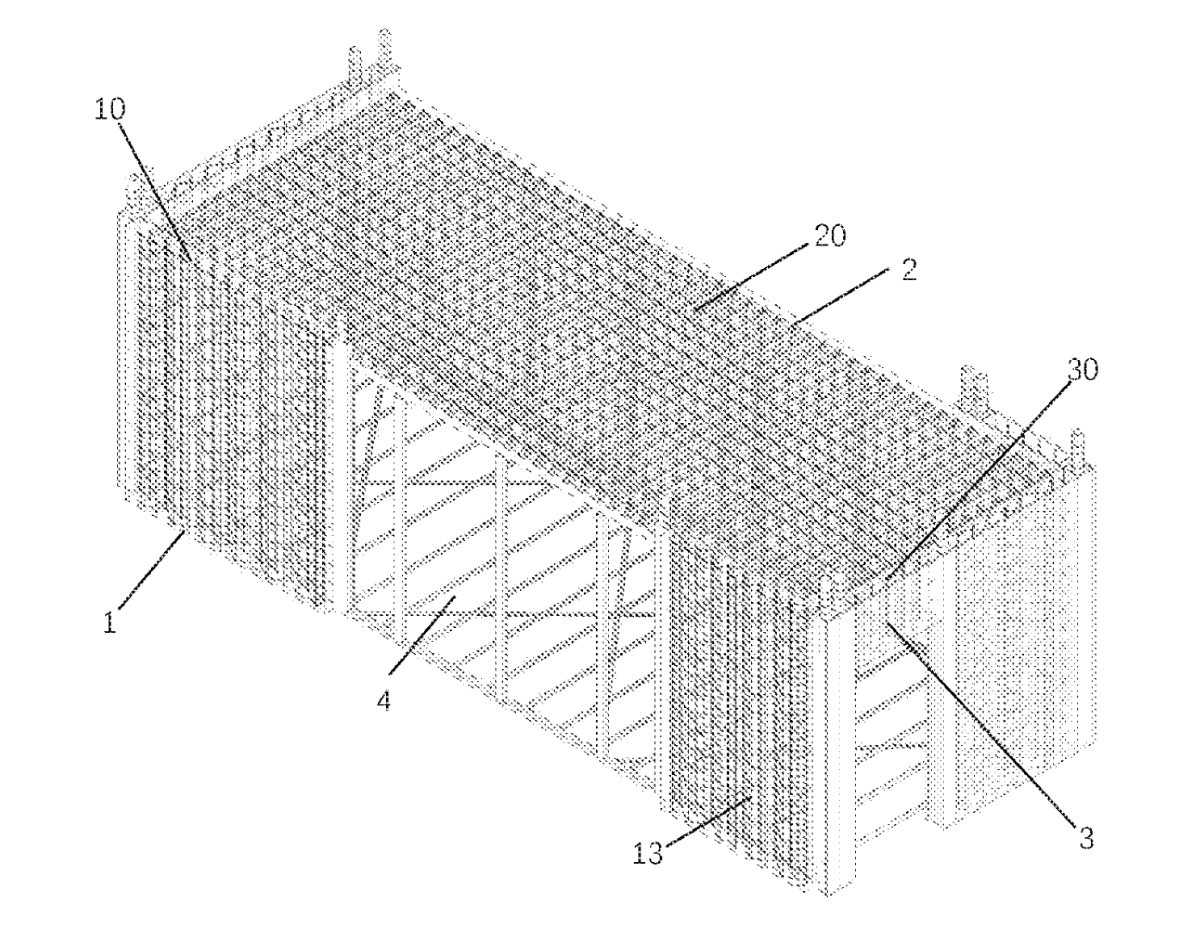

The engineering firm schlaich bergermann partner and the precast concrete component manufacturer thomas betonbauteile have jointly developed the first series-produced vaulted ceiling made of concrete. concap is a reinterpretation of the historic vaulted ceiling and sets new standards in the areas of elegance, resource conservation, technology integration and construction logistics. In addition to leveraging the striking aesthetics of its historical predecessors, concap also offers significant CO2 savings, simple connection details and intelligent technology integration.

Thanks to concap's efficient shape and structure, with a thickness of just 6 cm at its thinnest point, the same spans and load-bearing capacities of conventional ceiling systems can be achieved, but with a saving of approximately 60 percent of structural concrete. concap is not only efficient and sustainable, but also gives rooms a special elegance and spaciousness thanks to the characteristic flat arch profile, creating a bright, open atmosphere. As an exposed, high-quality precast concrete element, concap is filled on site with readily available granulated recycled bulk material. All technical building installations can be laid and installed in this infill, hidden from view.

Thanks to the different module sizes and widths, the ceiling system is suitable for office and residential buildings as well as industrial and commercial buildings. In combination with the infill, it meets all technical requirements in terms of ceiling loads, sound insulation, fire protection and user comfort.

concap is elegant and efficient

With its simple elegance, concap creates a generous and wide spatial impression. The basic ceiling soffit of concap is concrete gray and smooth as the elements are manufactured using the positive production process. The elements are supplied in exposed concrete quality and can be individually produced in various concrete colors as well as acidification and sandblasting.

concap also meets the increased requirements for sound insulation, 90-minute fire protection and enhanced user comfort for residential and commercial construction projects. concap was designed for a live load of up to 3 kN/m² and an additional permanent load (in addition to the infill) of up to 2.5 kN/m².

concap is space-saving and intelligent

concap enables a reduced total height of ceiling and installations, as all the pipes and cables required for plumbing and electrical installations can be integrated into the accessible infill under the floor covering. This eliminates the need for raised floors, even in high-tech buildings. The cables are routed either through recesses between the elements or in an intermediate layer above the element. This means that a total ceiling height of only 32 cm is possible. If desired, concap can also be used for room temperature control. In this case, thermal concrete core activation is achieved using capillary tubes already installed in the factory.

concap is tested and uncomplicated

concap complies with all applicable German building standards and can be adapted to technical EU standards if required. In addition, an assessment of the existing sound insulation is available for all types. This eliminates the need for time-consuming tests and approval processes so that concap can be included directly into the individual planning process. On the construction site, the precast concrete element enables a simple process and a rapid progress with a consistently high quality. concap is currently available for an axis grid of up to 810 cm in length, 270 cm in width and in various sound insulation and load-bearing capacity levels. Other individual dimensions are available on request.

concap is sustainable and recyclable

In direct comparison with an 8.1 m wide flat slab made of in-situ concrete, the ceiling structure with concap saves an average of 55 % CO2. This is made possible by the efficient load-bearing method of the arches and the use of granulated recycled material for the infill. At the end of a building´s life the non-destructive dismantling and uncomplicated reuse of the concap elements are possible.

Experience concap

On the concap website (www.con-cap.de), virtual rooms offer an impression of how the ceiling system works in the context of homes, offices, commercial and industrial buildings. In addition, an AR app makes it possible to virtually walk through individual rooms under the concap ceilings. Another highlight is the showroom in Hennigsdorf near Berlin. Here, the ceiling system can be experienced on a 1:1 scale. During an individual tour of the showroom, visitors can view and walk through an 8.1 m module with exemplary technical integration.

About the origins of concap

In the 19th and early 20th centuries, the so-called Prussian cap or Berlin cap was increasingly used for ceilings in residential buildings and in commercial or agricultural buildings as well as long-span factory halls. These historical vaulted or cap ceilings were crafted with stones or bricks. The construction was therefore time-consuming and required specialized craftsmanship.

Professor Mike Schlaich, who has been researching sustainable construction with concrete at the Technical University of Berlin for many years, came up with the idea of further developing the vaulted ceiling. As a partner of the renowned engineering firm schlaich bergermann partner, he found the ideal ally in Eckhardt Thomas, managing partner of the thomas gruppe. Working together as an interdisciplinary team, they succeeded in 18 months of intensive development work to rethink the historic vaulted ceiling and revive it as an intelligent, resource-saving precast concrete component.

CONTACT

concap

+49 3302 803 587