Unlocking the Future of Precast Concrete Manufacturing with AI

20.02.2024

Figure: iTheses

Figure: iTheses

In the ever-evolving landscape of construction, the precast concrete industry stands as a testament to innovation and adaptability. As the demand for faster, more efficient, and higher-quality building solutions continues to grow, precast concrete plants are turning to cutting-edge technologies to stay ahead of the curve.

Among these technologies, Artificial Intelligence (AI) is emerging as a game-changer, one which can revolutionize the way we manufacture precast concrete elements and which is ushering in a new era of efficiency and precision. How can the Precast Concrete Industry use AI?

Quality Control

Ensuring the quality of precast elements is paramount, and AI may prove to be an invaluable tool in achieving this goal. Machine learning algorithms can step into the role of meticulous inspectors, analyzing images and sensor data to identify even the tiniest defects.

Whether it's spotting fractures, spalling, cracks, imperfections, or deviations from design specifications, it’s possible that AI-driven quality control can elevate the standard of precast concrete manufacturing.

This will mean that only the highest-quality components make their way to construction sites, reducing rework, reducing associated costs, and enhancing project outcomes.

Proactive Maintenance

Downtime can be a significant setback in precast concrete plants. Could AI come to the rescue with predictive maintenance? By crunching data from sensors and historical performance records, AI algorithms may be able to predict when equipment is likely to fail and schedule maintenance accordingly.

This would result in reduced downtime, lower maintenance costs, and uninterrupted production—a win-win for both manufacturers and clients.

Efficiency & Optimization

Precast plants are complex operations, with a multitude of variables to consider. AI excels in optimizing production schedules, resource allocation, and material management. By analyzing historical data and real-time factors such as order volumes, raw material availability, and equipment capacity, AI can ensure that every resource is used efficiently.

The outcome is cost-effective production and timely deliveries that help to meet project deadlines.

Sustainable Manufacturing

Sustainability is a key focus in today's construction industry. AI can assist in optimizing energy consumption by adjusting equipment operation, HVAC systems, and lighting based on real-time demand and energy costs.

This can translate into energy savings but also a reduced carbon footprint, aligning precast concrete manufacturing with other modern and sustainable construction practices.

The Power of Data

The data generated by AI-driven precast plants is a goldmine of insights. By analyzing this data, manufacturers can make informed decisions, optimize processes, and uncover areas for improvement. This data-driven approach not only enhances efficiency but also fosters continuous innovation in the industry.

How is i-Theses Harnessing AI?

Developing innovative solutions for the precast industry is i-Theses’ mission. Two years ago, long before ChatGPT was commonly known, i-Theses decided to explore potential applications of AI.

In the precast flooring market, there is an undeniable evolution taking place. Automation and optimization of production has been focused on bed plotters, automatic saws and stacking. We now also see further stages in this evolution towards robotization.

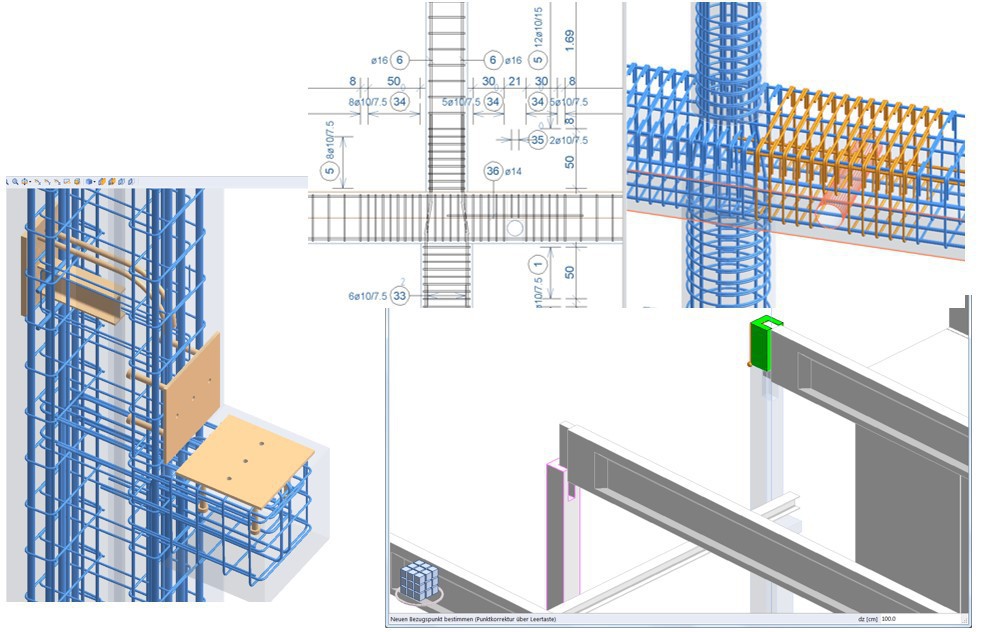

The creation of files to control plotters and sawing machines from various manufacturers has been standard in the company’s PlanDesk BedPlanner for years.

As a tool to increase your productivity and avoid production errors, i-Theses has developed M.a.X – “Multi-faceted AI-driven Planning eXpert.” With M.a.X, you can plan faster, evaluate millions of scenarios quickly, and make changes more easily.

Why multi-faceted? When planning, multiple optimization factors must be taken into account (sequences, shapes etc) and these are not always complementary. There is often no perfect solution, but M.a.X can help to find the optimal one.

Planning bed production while taking robot capabilities into account requires additional insight and knowledge, making error-free planning a complex goal. By deploying M.a.X, i-Theses can support your bed planning while taking the capabilities and limitations of the robot into account.

AI and Valid Concerns

As with any new technological development, there are always important questions to answer, and concerns to address.

For example, many people ask; will AI replace humans?

We don’t see AI as a job replacer, but rather as a tool to increase productivity. By leveraging AI, your teams can accomplish more work and handle planning changes easily, and more quickly. AI excels in evaluating millions of different scenarios, including some that a human might not have considered.

For users of software and equipment, a common question is; does automation mean users have to give up control?

Contrary to what is sometimes believed, automation with AI does not mean users have to relinquish control. Using M.a.X as an example, the AI provides optimized schedules, but it is always the user who ultimately has the final say. Users can make adjustments and modifications at any time.

Investing in the Future of the Precast Industry

As with other AI applications, this is just the beginning for the precast industry.

i-Theses has been investing hugely in recent years, both in new applications such as PlanDesk 360, and in broadening market availability.

Our development also includes the breadth of our product range, with extensive work going into applications for beams, columns, stairs and walls. Just as with flooring, we see many opportunities to use AI in the future.

As we move forward, the possibilities are boundless, and precast concrete plants that embrace AI are poised to thrive in the fast-paced and demanding world of construction.

CONTACT:

iTheses

Moortelstraat 27

Industriezone E17/3323

9160 Lokeren/Belgium

+32 9 33 88 252