3D concrete printing: stylish seating elements for Heilbronn‘s Dammschulen

By the investment in the technology of 3D concrete printing in 2020, the Röser IV GmbH located in Laupheim turned into the first German precast concrete plant equipped with a 3D concrete printer for large-sized concrete components, according to the manufacturer. The technology comes from Cobod and Peri. The pilot project for the application of open space elements from the 3D concrete printer, that we present you in this article, is about the schoolyard refurbishment of Heidelbronn‘s Dammschulen.

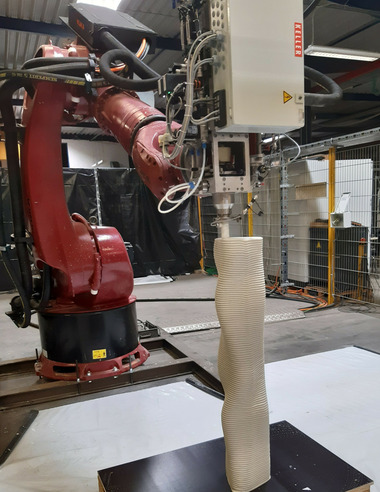

In 2020, Maximilian Röser decided to make an investment in the technology of 3D concrete printing. This turned the Röser IV GmbH located in Laupheim into Germany’s first precast concrete plant equipped with a 3D concrete printer for large-sized concrete components, according to the manufacturer. The technology comes from Cobod and Peri. The print space has a potential production area of 10 x 10 m and a printable height of 3.00 m. A modular expansion is possible. The investment, first of all, is aiming at simplifying and optimizing production processes that are outdated, physically demanding and thus time-consuming and cost-intensive. The focus is on special formwork construction as well as on elaborate special building structures which can hardly be accomplished, in particular, in times of a shortage of skilled labor. Due to the high degree of freedom of form and design, moreover, the process of 3D concrete printing also enables the development of new markets and an extension of the the existing product range, apart from the production of conventional special shapes.

The Röser IV GmbH located in Laupheim is part of the Röser Group and has specialized in the production of 3D printed precast concrete elements. Therefore, the production site in Laupheim has been tailored particularly to the requirements of 3D concrete printing and provides a lot of space for further expansions. The team behind the 3D printing process consists of experienced skilled workers from the precast concrete production as well as young engineers and innovation enthusiastic students.

Pilot project: „Boomerang“ walls for Heilbronn‘s Dammschule

The schoolyard refurbishment of Heilbronn‘s Dammschulen served as „pilot project“ for using open space elements from the 3D concrete printer. Dammschulen – consisting of an elementary school and a secondary school – are a representative, four-story school building being constructed at the beginning of the 20th century (opened in 1908) and that is characterized by immense sandstone façades.

Right from the beginning, redesigning of the two schoolyards was subject to the conditions to preserve the existing trees with improving their locations, to create barrier-free access to the schools and, in spite of the confined space, to integrate elementary school sports facilities (running track / broad jump / small playing field). Both schoolyards covering an area of 4,200 m² in total are clearly sloped. Maintaining the existing topography was imposed as part of preserving the building structure as well as the tree locations, partial areas intended for the school sports facilities, on the contrary, required leveling. The related differences in altitude of the site were to be integrated as walls or seating elements.

As in all public spaces, open space elements as well as seating furniture in schools must meet particularly high requirements in terms of ruggedness and durability. They must feature low maintenance and be easy to replace and/or reproduce. At the same time, they contribute considerably to the quality of stay in public spaces.

Demands on design and economic efficiency

The request for freedom of design and a correspondingly better integration of the seating elements into both schoolyards was the task assigned to Mr. Kühn, project manager of the Parks Department (Grünflächenamt) of Heilbronn. Several variants for the realization were contemplated in cooperation with the Pfrommer + Roeder landscape architecture office. The design idea of the Pfrommer + Roeder office to combine seating elements and walls in terms of design to retain differences in altitude and have them swing across the campus in free form like boomerangs was supported by the client. The elements developed should „swing“ through the yards as striking boomerangs (according to their project title) implementing the design topic „exercise and creativity“ by this sovereign, formal gesture in a creative way. They also form the thematic bracket of the two otherwise rather different courtyards. Beside the design aspects, the economic aspects had to be considered, too. Technical solutions were searched for to realize the various freeform elements with as little effort and costs as possible. Different material versions were examined, all of them, however, requiring individual production or formwork.

3D concrete printing with the approaches required

A TV report about the first attempts to use 3D concrete printing in housing construction inspired Mr. Kühn, who came across Röser GmbH in subsequent internet research. Hence, the search for the method of execution finally ended with the technology of 3D concrete printing. The technique offers the possibility to manufacture every precast part individually, without formwork and with optimized material expenditure.

The initial contact took place on the Röser GmbH location for 3D concrete printing in Laupheim. During this appointment, it soon became clear that 3D concrete printing was the solution for free planning and design without high formwork and capital expenditures. The conceptual design and planning could be implemented as requested. Further co-ordinations were made jointly in the constellation of client, planning office and the manufacturing plant.

Sampling and segmentation

The benches that were designed as solid bodies in the beginning of the planning process should be adapted to a 3D printable concept afterwards, which saves material, but nevertheless exhibits the same load-bearing capacity. A segmentation concept had to be prepared for the large-sized and slender components. The subject of transportation and handling on the construction site had to be considered as well. For this purpose, a reference / sample component was specified.

The test components made for this purpose were carried to Heilbronn, where they were installed in the proposed design to determine the suitability. In this way, the stipulated requirements on material and transport loads as well as construction loads could be examined and verified. The segment sizes chosen proved to be appropriate and were thus adopted to the entire project. Depending on the designed shape of the individual parts, additional reinforcement was included in the printing process, thus making the segments themselves dimensionally stable and covering the various load cases such as transport, installation, earthworks, and asphalt works in the finished state. Transport anchors, which are also used for conventional precast concrete elements, were incorporated in the printed structure in order to move and shift the components after the printing process. So as to ensure the suitability in 3D-printed concretes as well, test series were carried out in the form of mechanical pull-out tests. Hence, the capability of the transport anchors could also be proven for printed concretes and safe operations on the construction site.

Visual requirements

Central point of this specification was the architectural incorporation of the precast elements into the design of the two schoolyards. Next step was to improve the color shade of the concrete and the cement respectively. The cement gray of the first sample appeared too cool. The aim was to create a relatively bright, warm shade of gray having slight beige nuances, matching the color shade of the sandstone façades even better as well as the other materials used in the schoolyards (like wood, natural stone pavement, asphalt). This was achieved by the cement mixture of Schwenk.

The surface structure of the precast elements played an important role. The typical horizontal pattern resulting from the printing paths should appear as consistent as possible and by no means coarse or even like sausages. Hence, the idea to visualize the manufacturing process of the seating walls and to show the material „pure“, i.e., without any color coating, became part of the design concept.

To turn the precast elements printed as hollow bodies into seating walls with quality to stay, it should be possible to close them on the upper side with so-called seat covers. The wood coverings often used for classical benches were not durable enough for a schoolyard. Therefore, they decided to use cover panels made of recycled plastic, which were screwed onto the side walls of the precast elements by means of a substructure. At the same time, the seating walls were provided with a special color aspect, liven the schoolyards up visually.

„Cepriment 04“ of Schwenk Zement

The material contemplated in the initial phase of project planning had to be rejected in the course of the project unexpectedly, because the uniformity of the print pattern as well as the coloring of the finished concrete element did not meet the visual requirements of the client.

The Röser GmbH group of companies has been working together with Schwenk Zement GmbH & Co. KG as supplier of their precast concrete plants for many years now. It was obvious, on the part of Schwenk to develop in cooperation with Röser a printable material for this new and innovative application of 3D printing of concrete – supplied as binder compound with a maximum grain size of 4 mm and as silo material or in big bags. The „Cepriment 04“ dry mortar was mixed by Schretter & Cie., an affiliated company of Schwenk, located in Vils in Tyrol according to specifications and delivered to Laupheim. The Dammschule project in Heilbronn was presented in the course of the already ongoing printing tests at the location in Laupheim. Schwenk Zement expressed great interest in this project. The development department of Schwenk was able to incorporate the project-specific requirements directly in the material formulation by adapting the mix design of the 3D dry mortar material to the given conditions of water-binder ratio, mixing system, feed pressure and printing speed.

In addition to an adequate final strength of the fine concrete, the visual structure and the complete recyclability, the client also demanded resistance to freeze-thaw attack, which could be simulated and verified by means of the test specimens printed in the laboratory according to current test standards (CDF test). Moreover, a refurbishment concept had to be submitted in the event of damages occurring on the surface during the useful service life. It is based on the well-known and practice-approved measures for cosmetic repair of fair-faced concrete in building construction. The „status report on fair-faced concrete cosmetics“ (version December 2016) of the German Society for Cocnrete and Construction Technology (DBV - Deutscher Beton- und Bautechnik-Verein e.V.) gives corresponding guidelines.

Production and installation of the benches

The benches were manufactured with the aid of the 3D concrete printer of Röser GmbH in Laupheim. The total of 11 benches could be produced in an overall printing period of 25 hours. The benches were designed completely by CAD models, and thus could be handed over to the parties involved in planning without any problems, allowing a smooth cooperation with them.

Benigus Garten- und Landschaftsbau based in Backnang was awarded the contract for the realization and implementation of the outdoor facilities redesign of the schoolyard of Dammschule. Röser GmbH scheduled an appointment with Mr. Gans, the site manager of the company, at short notice, to talk about peculiarities concerning the positioning of the slender concrete components and to answer questions of the company. The outcome was an absolutely clean, professional, and flawless execution of positioning and incorporation of the concrete components.

Conclusion – Open space planning in an individual, sustainable and economical way

The project is the first open space facility manufactured in a 3D concrete printing process in Germany. A transportation and segmentation concept had to be worked out for the components in sizes of 8 to 13 meters, allowing the transport of large-sized, slender special components made in a 3D concrete printing process. Owing to the architecture, in particular, the bends and curved shapes of the benches should be maintained.

Thanks to the 3D printing concept, it was possible to save more than 2/3 of the concrete quantity needed for each individual segment. The material required for bench 1.2 was reduced from 1.83 m³ to 0.48 m³, for example.

The total of 11 benches were each separated into 2 to 5 individual segments, which were then manufactured monolithically in a 3D concrete printing process. The total of 36 segments with a length of 4 m on average were made on 5 production days and manufactured within an overall printing period of 25 hours.

Model-based planning allowed for an easy coordination among the parties involved in planning. In this way, it was also possible to generate the exact shapes and curves of the individual benches from the models.

Sustainability thanks to material savings

The 3D concrete printer was the only possibility to manufacture the unique and individually designed shapes of each bench and each individual segment without causing additional costs per segment. Even additional savings in material of nearly 70 % were possible. Due to the growing belief that a cost-effective alternative had been found and the openness of the client to use 3D concrete printing, it was finally possible that the swinging boomerangs could be planned and implemented as open space elements into the local conditions of the project. The outcome shows the cost-efficient realization of open space concepts that are demanding in terms of design using concrete components made in a 3D printing process.