A path to more ecological architectural concretes –

low-carbon white cements

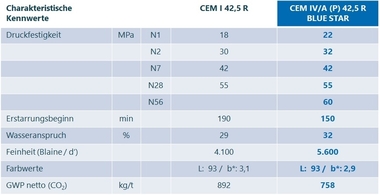

For more than 90 years, Dyckerhoff Weiss has continually contributed fresh ideas to building and designing with concrete. Differentiating between grades (“Starke Typen von Dyckerhoff Weiss”) made it possible even in the past to offer cement solutions optimized for use in different applications. Cement grades of increased fineness and thus increased performance (52.5) were made available, for example, which optimize the cement content in customer formulations by using different types of fillers.

It is now vital to also transfer white cements to a carbon-efficient future. Potential substitutes for clinker are found, on the one hand, in the field of natural and artificial pozzolans. Unburnt limestones may also be useful substitutes depending on the intended use.

Limestone powders are physically processed mineral additives that have been successfully used in the production of gray cement for several decades and, in a suitable color, may be a useful addition also to white cements. Natural pozzolans, such as those of volcanic origin, and artificial pozzolans, such as calcined clays, may also be interesting raw materials for the production of white cements.

Dyckerhoff experts have for some time been working on these alternative raw materials in laboratory and technical trials. In recent

months, the development stage has been left behind, the first successful plant trials have already been carried out at Dyckerhoff’s white cement production facility in Wiesbaden, and field applications of the cements produced with these materials have been promising.