Refractory industry and precast industry in collaboration?

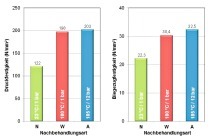

The idea is truly ingenious: can the waste heat readily available from processes in the refractory industry also be used in the production of precast UHPC elements? Recent results have shown that heat-cured UHPC (e.g. at 90°C) results in marked improvements in hardened concrete properties. On the basis of these results, the question arises as to where and how this heat could be made available on a cost-effective basis.

The refractory industry, with over 50 production sites throughout Germany and Austria, is active in many countries of the world. Many companies also offer, in addition to burned blocks, so-called unformed products, such as refractory concretes, and the precast elements made of them. The precast elements are typically delivered in tempered form, at drying temperatures of up to 350°C. This produces the waste heat of interest here. Some refractory plants, moreover, are equipped with grinding machines for processing large-size products with which, for example, glass tank blocks, installed without...