“Refractory industry as manufacturing partner for UHPC?”

The manufacturers of precast components are invitetd to meet the companies of the refractory industry as potential manufacturing partners now as suggested by the industry. The refractory company may be used as provider for the heat treatment. The manufacturer of precast concrete components may cast the components made of UHPC and carry them to the nearest refractory company for heat treatment and/or mixing and casting the formulation in the refractory company directly. In this way, it will be made even more use of the material UHPC.

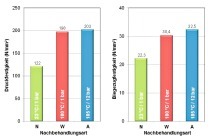

In the manufacturing process, structural components made of ultra high performance concrete UHPC need to be treated with heat, e.g., 2 days at 90 °C. However, precast concrete manufacturers are often not furnished with the appropriate generators. As a result, just a small number of structural components made of UHPC are offered on the market.

The symposium “Precast components made of UHPC – refractory industry as manufacturing partner?” intends to bring refractory companies, manufacturers of precast concrete components, potential “consumers of UHPC” as well as creative minds together. The...