Litronic – perfect moisture measurement

In many industries, the moisture content of raw materials is crucial to achieve the required finished product quality, which also applies to concrete production where accurate sand moisture measurement is of major importance to achieve the desired consistency and, ultimately, quality of the concrete.

The new generation of the Liebherr Litronic-FMS moisture measurement system has been improved even further. This system is in successful use in mixing plants worldwide. The setup allows for the integration of up to 16 interlinked sensors. Measured moisture values are aggregated in a mean calculator that forms part of the sensor electronics and transmitted to the controller unit to adjust the water content of the mix in the currently processed batch if and when required.

Mean value derived from up to 40 measurements per second

A comprehensive set of interfaces makes it possible to easily integrate the moisture measurement system into a wide range of production lines. The system comprises the “smart” moisture sensor, the electronics used for analytical purposes, and an easy-to-use software. It enables perfect moisture measurement and monitoring of values, as well as any adjustment or correction in the production process to adhere to the specified recipe parameters.

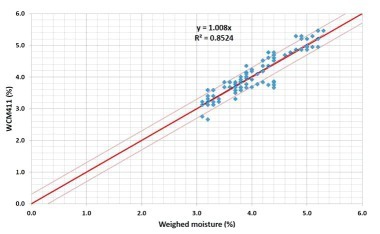

The integrated microprocessor performs up to 40 measurements per second to determine the arithmetic mean over the entire batching period. The moisture content of the material is measured in situ, which means that related values are made available in real time. The signal can be directly connected to personal computers, controllers or process control systems, such as the Litronic MPS mixer controller supplied by Liebherr.

Microprocessor makes results reproducible

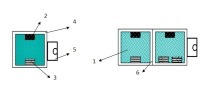

The microprocessor integrated in the sensor ensures reproducibility of results, which eliminates the need for recalibration when replacing the sensor. The microprocessor automatically evens out fluctuations in the material temperature that would have a distortive effect on measured values. The sensor can also be used to determine the temperature of the material. Fluctuations in the pH value of the medium will not distort measured values. An extremely wear-resistant zirconium oxide ceramic increases the stability and integrity of the sensor surface.

In concrete mixing systems, sensors can be placed, for example, in chutes underneath the silos or directly under silo outlets. Furthermore, sensors are optionally available in explosion-proof designs for dusts and gases according to the ATEX directives for use in potentially explosive atmospheres.