Shuttering panels: repairing long grooves easily

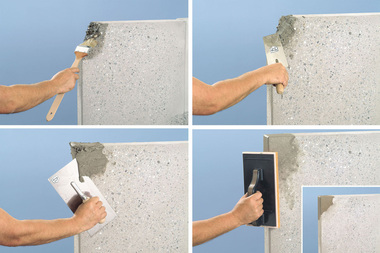

Shuttering panels have to withstand a lot of things on the construction site – vibrators or forklift trucks are often reason for cracks and scratches. If such damages are not repaired, they will cause so-called concrete “noses” after concreting, that have to be cut off manually in order to get a smooth surface again.

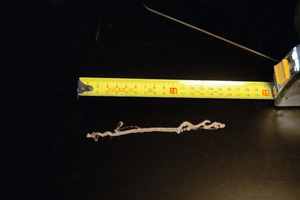

Emplica has found a possibility to repair even cracks having a length of up to 20 cm without much effort. For this purpose, the company has designed the longish repair patch “Plicafix 200”, using the same functional principle as the circular relatives “Plicafix 40 and Plicafix 60”.

Straight milling line thanks to a template

The repair patch is made of birch plywood with a brown coating on one side. The special feature, however, is the milling tool scoring longish grooves into the shuttering panel allowing “Plicafix 200” to sink into the panel in an optimum way. The four knives of the milling tool provide for a remarkable feed and are aligned as precisely as to allow inserting the “Plicafix 200” accurately fitting after milling. Emplica newly developed the milling tool for the longish repair patches.

A milling template, which is fixed to the edge of the shuttering panel by means of screw clamps, prevents the milling tool from slipping out of position. Thus, a straight milling line is created having the precise length of the “Plicafix 200”. Any kind of time-consuming re-working, as required by other repair methods of shuttering panels, is no longer necessary. The outcome is in a smooth, closed surface. Owing to the new repair patches of Emplica, it is no longer necessary to use the circular repair spots “Plicafix 40” in an overlapping way.

The new repair system of Emplica also qualifies for scratches in the center of the panel. However, it is not possible to fix the milling template there. Therefore, Emplica is urgently working on a solution in order to make such repair processes as easy as possible too – and make it quicker as a consequence.