Economically and environmentally sensible

As a manufacturer of concrete products one is often faced with a request for black concrete – not just anthracite. Permanent supposedly “black” coloring is obtained only with iron oxides (anchorage in the concrete, both mechanically and electrostatically) or with carbon black (purely mechanically anchored). Advantages and disadvantages are found in both variants.

Variants of the “black coloring”

The iron oxide, the safe version of a “black coloring”, unfortunately, does usually not achieve the desired color intensity, even at high doses, despite further developments of some products on the market. Anthracite colors are available that are stable and durable.

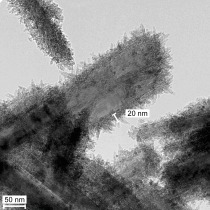

With the use of carbon/soot a deeper blackening can be achieved. Due to only mechanical anchoring in the concrete, the “blackness” and the durability are extremely dependent on the particle size and the raw material mix for the production of carbon. Necessary for the anchorage would be a high...