Change and adjustment to shifting market focus

Amtekno LP sells automated wet-cast production equipment supplied by BFS Betonfertigteilesysteme GmbH in North America and Latin America. Its customers include manufacturers searching for a value-added opportunity to produce concrete products with higher margins. This equipment can be used to manufacture a large number of products, including paving slabs, steps, patio stones, walls and veneer stone. With wet-cast products increasing in popularity throughout the world, Amtekno LP and BFS stand ready to provide customized solutions to production facilities of any size.

Amtekno LP, a U.S.-based company in Atlanta, Georgia, has been providing customized solutions for concrete product manufacturers for eight years. The company’s focus is primarily on wet-cast and dry-cast production equipment, molds for wet-cast production, and technical and sales consulting. Amtekno LP has seen an increase in wet-cast inquiries and sales during the past two years. Ray Clark, Vice President of Sales for Amtekno LP, attributes this specific interest in wet-cast production to market shifts around the world. “Customers I speak to on a daily basis tell me that architects, contractors and homeowners are looking for products other than the traditional dry-cast paving stones,” Mr. Clark reports. “With the advent of automated wet-cast production and limitless product opportunities, wet-cast provides manufacturers with an entire new line of products to offer to the most discerning of their customers,” he says.

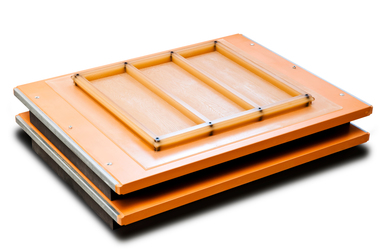

However, wet-cast products are not new to the concrete products business. Companies throughout Western Europe have been manufacturing wet-cast products for many years. The products, however, continue to be revolutionized. Products like travertine, slate and other natural stone look-alikes are now most popular. There is an increased demand for other natural-looking products like wood and granite. Successful wet-cast manufacturers have mastered the art of turning concrete into products that mimic these natural products, at a sales price that is often much lower than the natural products. “Even I have a difficult time distinguishing the concrete products from the real products,” Mr. Clark states. With new coloring and concrete dosing technologies, the possibilities of re-creating natural products in concrete products are virtually limitless.