Value stream mapping

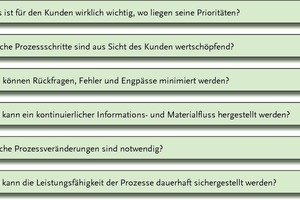

Today, industrial enterprises are forced to identify and fully utilize cost saving potentials in all areas of the business. The related activities focus on the restructuring and streamlining of all operational workflows and business processes. In many cases, however, the actions taken to implement such plans are targeted at isolated process improvements not interlinked with each other. Such isolated endeavors do not sufficiently consider the entire value stream, which is why they do not result in ground-breaking success stories.

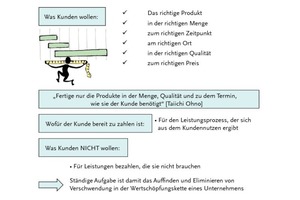

Just like other sectors, the building materials industry is faced with the challenge of marketing its products at reasonable prices despite high materials and personnel costs and the ever-growing demands of their customers (Fig. 1). There is a trend towards flexible factories and companies operating at highest productivity levels despite changes in the number and types of products manufactured.

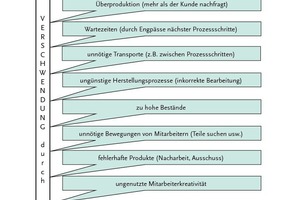

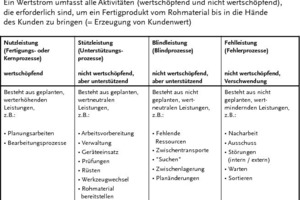

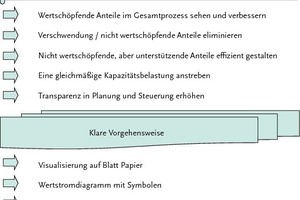

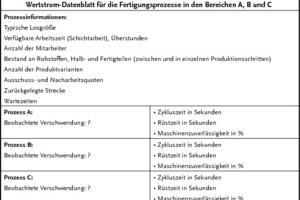

Existing saving potentials can be identified using value stream mapping, which is a lean management method. Another term commonly used to refer to this concept is “value stream design”. This article sets...