A New Factory set up by Bortubo/Spain

In Marchena, Andalusia, Bortubo Group and partners have set up a complete production line for the manufacture of a wide range of pipes and box culverts in an existing, recently acquired production facility. This move appears to be a bold, anticyclical investment against the backdrop of the current situation of the Spanish construction industry. All the more reason to publish a site report that looks more closely at this installation.

The group

“Geysermarkt” is an artificial name that stems from the original establishment of the company. In addition to Bortubo, Placasmurcia and the old shareholders have a stake in the business. Bortubo Group is one of the leading Spanish producers of civil engineering products made of concrete. The company is a medium-sized, family-run business. Established in 1988, the group has a relatively short corporate history but has been expanding its activities considerably in this period.

Total 2008 sales amounted to 22.4 million euros (compared to 25.7 million in the peak year of 2007). This result was based on a production output of slightly over 300,000 tonnes (2007:slightly over 350,000 tonnes) achieved by 46 employees.

The company is being managed by one of its major shareholders, José Pujante (Fig. 1), but several other family members also hold senior management positions. Over the years, the business was positioned strategically to cover the entire value chain of the industry. For instance, Bortubo can draw from its own raw materials resources, which include one quarry situated close to Murcia that provides a capacity of 650 tonnes per hour and several other quarries near Albanilla with a total capacity of 1,100 tonnes per hour and enormous reserves. As a matter of course, this degree of independence is an invaluable benefit for a precast element producer.

The main production facility is situated near Murcia. On this site, the company started producing DN 300 to DN 600 concrete pipes (i.e. a very limited range) in 1988. Today, the production site occupies a total area of over 150,000 m², of which 16,000 m² are areas covered by the factory buildings. The three factory building sections are used for the production of a full civil engineering range that includes concrete and reinforced concrete pipes in any conceivable dimension, box culverts and all associated custom elements, as well as paving blocks, curbstones and other road construction products, such as concrete crash barriers.

Jacking pipes are a major product line of the business – even their steel collars are produced in-house.

Fig. 4 and 5 show examples of the diversity of the product range.

The plant and equipment provided in Murcia comprises:

» 2 Schlosser-Pfeiffer radial presses (RP 830 and RP1235)

» l3 Schlosser-Pfeiffer Variant machines (2500, 3600, 6000)

» 1 Hess circulation system with a RH2000 VA unit

» 1 Prinzing Mistral unit

» 1 Prinzing Blizzard unit

» 3 MBK cage welders

» 1 MBK test rig for pipes and testing equipment for curbstones and paving blocks

» 4 mixing units

» 1 pipe mill (MBK)

The Fig. 2 side shows a view of the main factory but does not include the recently constructed third building section.

The Marchena factory

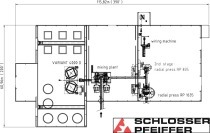

The above image on the right-hand side provides an overview of the production site. The factory was originally part of the Spanish Fabrega Group. Following the take-over of Fabrega by French Bonna Sabla Group, the “Geysermarkt” business with two factories – the Marchena production site referred to above and another facility at Almensilla (also close to Sevilla) – was separated from the group and acquired by Bortubo.

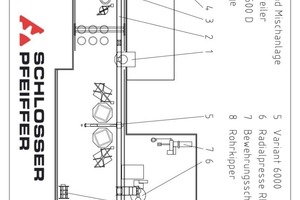

About two and a half years ago, the company decided to completely redesign its production and to equip the factory with state-of-the-art plant and machinery in order to serve the entire Andalusian market from there. Fig. 3 shows a complete view of the production facility, including the existing old factory building and the generously designed new building. The entire range of plant and equipment newly installed at the Marchena site includes:

» 1 mixing unit, supplied by Frumecar

» 1 Schlosser-Pfeiffer Variant 2500 (single unit but prepared for extension to double unit)

» 1 Schlosser-Pfeiffer Variant 6000 D

» 1 Schlosser-Pfeiffer RP 1235 with stronger drive unit to also produce DN 1500 pipes

» 2 MBK cage welders.

All these installed machines are completely new, which represents quite a sizeable expenditure given the current reluctance to invest seen in the industry.

However, not all of the machines are operating to full capacity as a result of the market situation. For instance, the flexible design of the Variant dual unit is utilized whereas the single Variant line is currently put on hold.

The mixing unit

The mixing unit has a capacity of 2 m³ and can thus supply all three machines. Five different aggregate grades are available. They are stored in a tower system providing a total capacity of 240 tonnes, which is sub-divided into two bins of 60 tonnes each and three bins of 40 tonnes each. The tower system is fed via a bucket conveyor (Fig. 7).

The system uses a weight-controlled batching process. Vibrating batching chutes convey the material to a weighing conveyor that feeds the material directly into the mixer. Moisture measurements and adjustments of the sand/water ratio are not required because the aggregates supplied are of an extremely uniform quality.

The mixing unit was installed in the central section on one side of the factory building, which enables material to be fed to all three production machines via a straight bucket conveyor without gradient that needs to overcome only a short distance.

The Variant 2500 E pipe machine was not in operation on the day of the site visit. Although significantly smaller, this machine is equipped with the same vibrator as the Variant 6000. No contour control is included because only circular elements are produced on this machine.

The Variant 6000 D machine has been designed for the production of elements with any contours, which is why it is equipped with a control unit featuring state-of-the-art software and drive technology. Both the rotary feed conveyor drive and the rotary drive itself are servomotors that include the feedback of actual parameters and a very high degree of accuracy (+- 1 ° for the rotation and +- 1 mm for the travel drive) (Fig. 8). The associated synchronization software is used to continuously adjust the conveyor position to its corresponding filling speed.Element contours are defined in a very user-friendly manner using a “teach-in” process on a touchscreen (Fig. 9).

The filling level is controlled by a laser system that yields very accurate results. When concrete feed has been completed, the press head with the spigot end profile travels across the mold and performs the final compaction step. For the first time, this method ensures a fully automated process also for this machine – even when producing items with sophisticated shapes, such as rectangular and oval.

Particular emphasis was also put on the safety of the control system. For instance, a modular, expandable safety controller monitors and checks all emergency stop switches and individual safety switches for any occurring short circuit or cross connection.

After completion of the compaction process, a 32-tonne crane moves the complete set consisting of bottom pallet and mold to the curing area, where the lock that holds the mold and bottom pallet together is released and the product demolded. If required, top pallets or supporting profiles are attached, and minor rework is carried out.

At the same time, the crane travels to prepared sets of bottom pallets and reinforcement cages and adds them to the mold shell.

On the day of the site visit, box culverts were produced on one side of the machine while standard circular pipes were manufactured on the other. This meant that the removal and fitting of new pallets was performed in an alternate arrangement. This way, the flexibility and performance of the machine was utilized to the highest possible degree while keeping labor cost to a minimum.

1235 radial press

This machine can produce pipes in nominal bores of up to DN 1500. Its mechanical design is equivalent to the tried and tested predecessor models, which also permits a smooth exchange of molds with the Murcia plant. On the other hand, however, the control system of the radial press reflects the state of the art as presented at bauma 2010: all paths are measured using laser systems and shown in the actual unit, i.e. mm (Fig. 10). This approach eliminates the need for any mechanical parts prone to breakdown or malfunction.Likewise, pressures measured by dedicated sensors are displayed in bars. This arrangement is of great assistance to the machine operator – who constantly changes his position because he also needs to operate the forklift – when it comes to optimizing the machine settings. When the best setting has been identified, it can be stored on a product-specific basis. This setting can then be easily retrieved after each change in the product dimensions.

The control unit includes a fault diagnostics system. Any disruptions of the automated process or errors committed by the operator are detected and displayed. This fault diagnostics system also includes the monitoring of the circuit breakers of the individual motors. The control system is battery-buffered and retains all stored variables even in the event of a power failure.

Particular emphasis was put on the safety features of the machines because they include a large number of moving parts and thus potential risks of crushing or shear. This especially applies to the turntable with mold and the forklift used to transport this mold.The machine was thus completely blocked off by wire mesh guards that only allow for a single, strictly defined point of access (Fig. 11), which is secured by two light barriers arranged in series so that the control system always “knows” the direction from which the access point was used.

A manual controller has been fitted for cleaning movements of the machine. This controller includes clearly designed pictograms that once again highlight risks and hazards (Fig. 12).

Another hazard had previously been posed by the risk of falling during cleaning of the feed table. Although handrails could be used to secure the table toward the outside, only a safety harness provided appropriate protection against falling into the mold. However, the degree of acceptance of this precaution was obviously low among the workforce.

In this respect, Schlosser-Pfeiffer has now implemented a novel, consistent solution: the table guide and distance measuring system have been extended toward the bottom to such an extent that the table can be lowered to a height that no longer poses any risk.Overall, this permits the conclusion that any and all conceivable arrangements have been made to ensure a maximum degree of safety at work.

Forklifts are used to transport the finished products to the curing area and to feed the machine with the manually prepared sets consisting of bottom pallet and cage, complemented by the mold shell. Mr.Pujante has always been in favor of using this transport system, as opposed to a fully automated system. The very small number of people required for this work step makes it difficult to justify any major investment in a fully automated solution, be it a “moving floor” or an “open floor” design.

Cage welding machine

An MBK machine is used for this purpose, just like at the Murcia plant where several such machines were incorporated in the production line (Fig. 13). The business does not currently see any need for change because this machine has delivered outstanding results so far.

The Products

The Marchena factory exclusively manufactures pipes and related products – no blocks or similar items. However, the range of the manufactured products is extremely wide nonetheless: it includes reinforced concrete pipes from DN 300 to DN 3000 but also giant box culverts (Fig. 14) and the complete range of custom products and accessories for pipes, such as elbows or connecting pieces.This diversity is shown in the picture detail on the right-hand side. The large number of different products is all the more remarkable because the picture was taken only a few weeks after the start of the commissioning process.

Market situation

Fortunately, the opportunity arose to engage in a longer talk with Mr. Pujante, who had a very pessimistic view of the current situation of the Spanish construction industry. According to him, the problem was caused by the financial bottleneck of the government, all the more so because the business had to rely exclusively on public projects due to the offered product range.The current degree of machine utilization amounts to less than 50% of the theoretical single-shift performance. Two years ago, the factory had still been producing in two shifts, achieving a utilization of over 100%.

As referred to above, this situation was also reflected by the current production processes: the Variant 2500 machine was put on hold completely whereas a circular pipe was produced on one side of the Variant 6000. The smaller machine would have been the better choice for this pipe but the large machine could at least be utilized fully. Likewise, the radial press used only one mold shell because maximum output was not required at this stage. Nonetheless, Bortubo still supports the investment made, mentioning that the business would be in an ideal position to ramp up capacity again once the construction sector begins to recover.

Summary

Amid a dire economic situation, a completely new precast pipe factory was set up in Andalusia. Bortubo Group intends to further expand its business despite any adverse conditions in the short term.The factory is well-prepared for any future challenges due to its installed radial press and two Variant units.