Ameritex Pipe & Products LLC and Schlüsselbauer intensify collaboration

The decision-makers at Ameritex are setting the course for continually expanding its market position through quantitative and qualitative growth and by goal-oriented investment. Among the means for achieving this goal, in addition to higher production volumes, measures to enhance and ensure quality are now being implemented with new production methods. The findings gained from several new highly automated production facilities confirm that the managers at Ameritex made the correct decision to collaborate with Schlüsselbauer as a new technology partner in both production segments – wetcast and drycast.

Each new production unit and the immediately apparent benefits are followed by considerations for further automation as well as by further development of the product range with high-quality molds and handling components. Especially in a dynamic market environment, it is strategically important for the fast-growing manufacturer Ameritex to have suitable partner companies to ensure ongoing productivity enhancement and to achieve the planned growth.

Successful partnership toward quantitative and qualitative growth

In line with its strong position in the market for concrete components, the range of pipes and manholes manufactured by Ameritex Pipe & Products is steadily growing. This positive development within the company – and together with changes in the area of production technology providers – has meant that it became necessary to completely replace previously used machines and systems. Collaboration between Ameritex and Schlüsselbauer Technology already began several years ago when the decision was made to invest in the first highly automated production plant for mold-hardened manhole components.

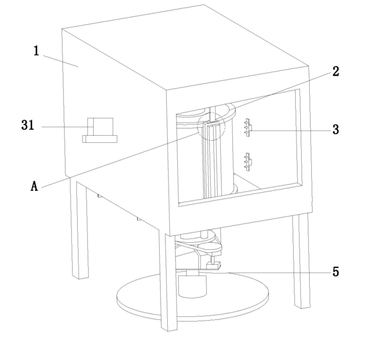

The mold-casting concept at Schlüsselbauer Technology that has been continuously developed over more than two decades, allows not only integration of cast production in a fully automatic handling concept. In addition, Perfect Forming Technology stands most of all for mold components of high precision as the basis for extremely high concrete component quality. All contact points for sealing, tooling, and drive functions are fully automatically processed in the mold construction technology provided by Schlüsselbauer Technology. Individual parts of the molds, such as bottom pallets or core elements are adapted and integrated into the mold.

More than 100 products per shift

All of this ensures the basis for durability and profitability of investment in the mold park. Moreover, Perfect Forming Technology also provides a basis for manufacturing high-quality components without compromising on accuracy of fit, tightness and surface quality. In addition to the many years of Schlüsselbauer Technology in implementing automated wetcast systems, the quality of the molds was for Ameritex Pipe & Products a significant criterion for making the investment decision. Rocky Lorenz, CEO Ameritex Pipe & Products LLC summarizes: „We evaluated casting mold suppliers from all over the world. In the end, we found Schlüsselbauer to be a supplier that would be able to best fulfill both tasks – supplying high-quality casting molds for several products and adaptation of the automation of wetcast production to all our customers’ requirements.”

This machine likewise manufactures standardized rectangular components and manholes: in addition to the individual circular manhole bottoms in always two nominal widths, with or without buoyancy protection. The work process is always basically the same here – beginning from opening the molds, leading through demolding of the products and progressing all the way to setting up and renewed filling of the molds. Due to the great number of setting-up stations, molds requiring different set-up times are flexibly and quickly moved through production, without causing bottlenecks in the production flow at any point. And planning of day-to-day production can be easily adapted to fluctuations in demand without having to daily reschedule the tasks of individual workers. In this way, based on a flexible production concept, significantly more than 100 mold-hardened products can be manufactured in one extended shift.

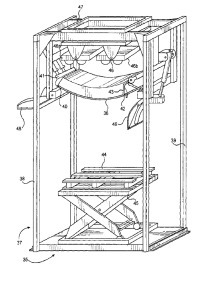

New type Magic manhole ring machine

The machine system most recently put into operation is a type Magic manhole ring machine. It enables production of manhole components up to an interior diameter of 1,500 mm (60 inches), or of rectangular construction of outside diameters up to 1,800 mm (72 inches). The associated concrete filling process was designed for handling the circular product sizes 48 and 60 inches, and the 60-inch rectangular products. Furthermore, a reinforcement feeder for all product types and nominal widths was integrated. The fully automatic Transexact system implements transport of the immediately demolded products into the curing area, and of the hardened components to the palletizer. In this manner, the hardened products are transported over optimized travel routes in the curing area, and the hardened products are picked up and replaced by fresh products.

Manipulation without human intervention of the products in the curing area leads not only to a reduction in personnel costs, but most importantly prevents all damage to the products and the production technology that are virtually inevitable with human handling in concrete works practice.

CONTACT

Ameritex Pipe & Products LLC

8489 Waukegan Road

Conroe, TX 77306/USA

+1 936-231-5660

Schlüsselbauer Technology

GmbH & Co KG

Hörbach 4

4673 Gaspoltshofen/Austria

+43 7735 7144-0