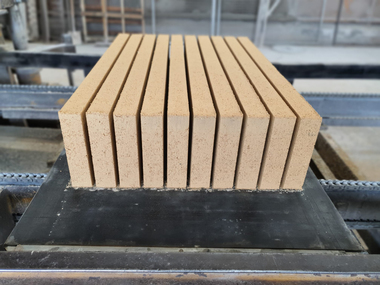

Standard pavers of premium quality

The small town of Senec just outside Bratislava has been a production site of precast concrete elements for over fifty years. The history of ELV PRODUKT a.s. began with the production of spun concrete poles, which were later complemented by steel poles for the operators of power transmission systems. In 2007, the company made the decision to expand its product range to include pavers, and subsequently invested in a new production line.

The decision to expand the production capacities to include pavers and blocks was made in western Slovakia at a time when there was no thought of the global financial bubble yet and nobody was even considering such an economic development possible. Since that time, the company’s success has been based on three mainstay activities: spun concrete poles, steel poles and concrete products. Production is taking place on a company site of 12 ha in size, with an adjoining area of 3.5 ha recently cleared for the block machine.

ELV a.s. does business as a joint-stock company. It is held by some major shareholders and several minor shareholders and is governed by a supervisory board. Both the supervisory board and the company management have been holding their positions for over ten years, determining the company’s course of action. In the past, the manufacturer was a state-owned corporation, doing business as a service company for the power industry.

This has remained a mainstay activity of the company even today as ELV, employing a staff of around 150, continues to be a successful producer of concrete poles and solid-wall steel poles for Europe’s energy groups. RWE, EON and others count among the loyal customers of the Slovak manufacturer. This, in turn, required the company to introduce a German supervising authority so as to improve transparency in terms of its competitiveness vis-à-vis other suppliers. As a result, ELV has been supervised by Güteschutz Nord e.V. (registered quality assurance association for manufacturers of concrete and precast concrete products) for several years. Graduate engineer Gustáv Časnocha, Chairman of the Board and Managing Director of ELV, comments: “Unfortunately, the additional costs incurred by third-party supervision are usually not paid for by the customer. We have taken a firm stand, however, to ensure that the prices can be placed in line with market standards, enabling us to supply the high quality specified by the customer.”

The company’s experience of many years is complemented today by its convenient geographical location in Europe. The distance to Vienna from the company’s yard is only 70 km, and Budapest is less than 200 km away. The neighboring Czech Republic with its currently strong economy offers equally good sales and commodity markets. It is mainly ELV’s favorable location within the infrastructure network of the EC, however, which offers good conditions for both purchasing and sales.

The decision to purchase a paver machine was made in 2007, and the purchase contract was signed in the spring of 2008. Summing up, Gustáv Časnocha reflects: “The machine was put into operation in 2009. In the beginning, we did a lot of trials, however, producing small amounts only. After a while, we found the ideal combination of materials thanks to the support of our cement supplier, and production could begin in earnest.” There can be no doubt today that the Senec based company produces gray mass market pavers of an entirely flawless surface quality. Both the high quality and the finely textured, impermeable face mixes have rarely been seen in the gray pavers to date. Nevertheless, the company management maintains its modest stance: “We have not yet completed our testing or running-in phase. We have many products yet to be tested, some colored mixes need to be ascertained, and last but not least we also want to drive further developments.”

The machine built by German manufacturer Rekers has commenced full production this year or, to be more precise, is producing in extended shifts of approx. 10 hours per day. This is necessary in order to be able to respond to market demands and to have standard products for both private customers and key accounts (building material suppliers, building contractors) available in stock.

Decision for growth

In our industry, the “crisis” has resulted in many projects being either postponed or cancelled altogether due to the instable economic situation. Not so at ELV, however, where the question was raised even earlier: will it really be worthwhile to expand production to include concrete products? What quantities will have to be produced on a daily/annual basis in order to be profitable?

Statistics of the “paver nation” Germany were looked up, and the numbers were evaluated. The result was encouraging, for the sales of concrete products remained fairly constant even in times of economically weaker periods. In addition, there were the potential reserves/demand in Slovakia.

Cool calculation, good decision. The only remaining question was which manufacturer to purchase the plant from. German manufacturer Rekers had been on the shortlist right from the start. The company had submitted an attractive offer for an almost fully automated machine which perfectly fitted the concept developed by ELV. Gustáv Časnocha stresses: “We consciously decided not to purchase the most low-priced machine but the one that fitted best in our overall concept while guaranteeing quality and reliability at the same time. And we can say today that Rekers offers excellent service and support fully tailored to meet our requirements. In addition, we have had online monitoring included in our contract.”

It is evident from the interview that the company combines economic thinking with ecologically sound action. An important aspect influencing the decision to purchase were labor requirements: the block machine can be operated by a crew of 5 to 6. This number includes the forklift drivers to be deployed on an as-needed basis.

Since introduction of the euro in 2005, investments in both infrastructure projects and the private sector have increased significantly, a fact which may also be attributable to the simplification of foreign investments.

It goes without saying that ELV also notices the effects of regional competition coming from the Czech Republic, Hungary, and Slovakia itself.

Product portfolio

The KRS 4 block machine manufactures concrete products from 50 mm to 300 mm in height. Pavers with integrated spacers at the sides are standard also in Slovakia, the spacers being between 1.5 mm and 3 mm in size depending on the product. The molds for paver production are purchased from Rampf, Kobra or Techmatik. The basic product portfolio presented in ELV’s current product catalog includes interlocking pavers (double S), rectangular pavers, flagstones, grass pavers, curbstones and edging stones. Tactile pavers are also part of the company’s product offer.

A Colormix module was factored in as early as the planning stage. It is to be installed in the short term once production of the gray range fully meets the requirements of the company management and better estimates are available to assess potential sales of the shaded products.

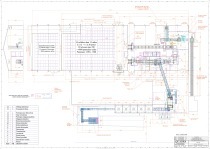

Plant design

The KRS 4 universal block machine is equipped with computer control, hydraulic power pack and the proprietary fully variable servo drive vibration system. This machine type is suitable for the production of a wide range of concrete products of premium quality.

The main frame is of welded design (rectangular steel sections), thus offering maximum stability and durability. To ensure the correct alignment of vibration axis and amplitude, the mounting plate has been finished to maximum precision.

The core concrete hopper and accompanying feed box are mounted on a separate frame. A load cell integrated into the core concrete hopper detects the current filling levels and forwards them to the central control system.

The central control system is a special feature of this type of plant, with all control pulses being emitted from the control panel installed next to the fully enclosed machine. The transfer car including elevator and lowerator (24 levels in single storage) is supplied with control pulses via a trailing cable. All modes of operation can be selected via a Siemens S7 control system.

The servo drives for both the core and face mix feed boxes are equally unique in design.

The feed boxes are of self-supporting design and are moved along guide rails. An adequate travel distance over the molds ensures that the face side of the mold is always sufficiently filled. The patented mold changing system comprising a dual swivel arm enables the molds to be changed in less than ten minutes.

The vibrating system is governed by frequency and amplitude control, which enables absolutely vertical vibrations to be transferred to the single-part vibrating table (vibrating force 225 kN at 3,000 rpm). Optimal filling and compaction are reflected in the high bulk density and strength of the concrete product. The vibrating system comprises two identical, symmetrically arranged, counter-rotating unbalance units.

In addition to the standard operating mode, the vibrating system features two “Rekers type operating modes”. The first mode enables a horizontal vibration component to be added during preliminary vibration, thus ensuring optimal filling of the mold, for example, when producing thin-walled products. The second mode of operation allows an offset to the left or right during the main vibrating process. This helps to compensate for minor differences in product height when a fixed height has been specified instead of a fixed main vibration period.

The machine is fully enclosed, with brick-built walls to ensure efficient soundproofing.

Board transport inside the machine is effected by a walking beam conveyor which is also driven by a servo motor. This type of board transport ensures exceptionally gentle handling of the green products while causing only little or no wear at all on the vibrating table. The production pallets (Rettenmeier softwood boards) carrying the freshly produced concrete blocks are driven to the curing chambers by means of the centrally controlled transfer car.

Following the grab / cuber, the separate layers are covered with a plastic net and then stacked on a pallet (1200 x 800 or 1000 mm respectively) to form a pack that is automatically transported to the removal conveyor. Vertical strapping of individual layers in the pack is also performed in an automated process.

The overall safety concept of the plant is based on light barriers. The entire production process has been separated into different sections and is secured against unauthorized access by means of the light curtains, thus guaranteeing good access and maximum safety standards at the same time.

Source materials and quality control

The concrete plant in Senec is fortunate to be located in a geological region which is rich in gravel resources (near the Danubian Lowland). Sand and gravel are of excellent quality and are complemented by cement provided by a reliable cement supplier.

The aggregates are temporarily stored in covered storage boxes prior to being transported, via a hopper and skip hoist, to a large bin. The bin holds all types of aggregates and, via a conveyor, empties them into the mixer in a vibrating movement. The core mixer was supplied by Pemat, the face mixer was purchased from Slovak manufacturer QEL.

Liquid colorants are used for the manufacture of colored products. The range of colors currently on offer includes red, black, brown, yellow and green.

Factory production control is performed by an outside testing laboratory which is EC approved and can therefore help to dispel any doubts related to product deliveries from Slovakia to other European countries, or issue the required product certificates. The company management recalls the initial stages of collaboration with the laboratory: “We never had any problems with proving or implementing quality standards and the measures we needed to take. The accompanying paperwork was what was really complicated and time-consuming.” Today the company is proud of the surface and block qualities achieved and delighted at the EC certificates issued for their products to date.

Outlook

ELV is especially satisfied with the quality of its mass market products and the cycle times achieved as everything is well within the target the company set for itself. The manipulator required for rejection during quality control will be installed within the next few days as the production of larger items (slabs, curbstones etc.) has clearly shown that this will allow interventions in the production process to be performed much more quickly and also in a more ergonomically efficient way.

Dust extraction in the production building has already been implemented, the air on the green side being extracted and conducted away via a wall opening.

The company states that it has currently achieved only around 70% of its targeted production capacity. This sets a clear goal for 2012: an output of 100%.¢